|

By Ricks56 - 11 Years Ago

|

My 56 Fairllane is not getting oil to the passenger side rocker arm assembly. I have removed the assembly, found the rocker shafts clean and clear. I checked the passage thru the head, clear and clean. I put carb cleaner in the oiling hole and let set. The level did go down a small amount. Cleaned out the hole several times then tried to blow 120 psi air down the hole and could not.

Here are my questions...

The motor was supposed to have been rebuilt sometime around 2012. Internals appear very clean. The driver side is getting PLENTY of oil. Are both sides fed from the same cam bearing? The motor is believed to be a 312 and was made in Jan 1956. Not sure what was replaced for the rebuild. If it has a crossed drilled cam, maybe the holes were not lined up when I tried to blow out the passage? Is it possible that I have to turn the motor over until the holes are lined up?

I figure I will have to pull the head next spring and check the head gasket and the oil passage in the block. Does the fact that oiling on the driver side of the car is more than enough indicate that the cam bearing is passing oil ok? Also, I read somewhere that there was TSB from Ford about a fix for an imbalance in the oiling (assuming that both sides are fed from the same cam bearing). Any thoughts?

Thanks!

Rick

|

|

By charliemccraney - 11 Years Ago

|

The term "rebuilt" is used pretty loosely. Without documentation, you just can't know what was done.

Both are fed from the same bearing. If it does have a cross drilled cam installed, then you may need to turn the it. If the bearings were replaced, then it is possible that the bearing is installed incorrectly.

On an old, worn engine, the passenger's side tends to stop oiling before the driver's side so oil to the driver's side does not necessarily indicate that everything is ok with the bearing.

|

|

By Ricks56 - 11 Years Ago

|

|

Thanks for the reply Charlie!

|

|

By schlockrod - 11 Years Ago

|

|

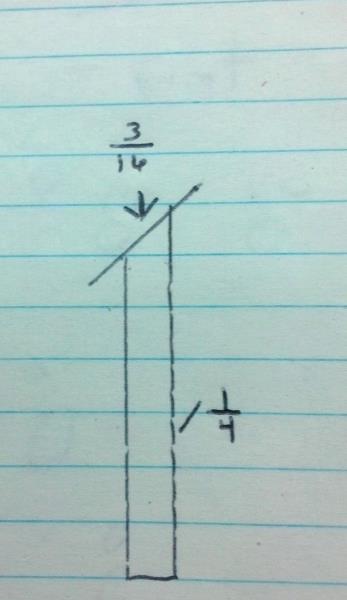

My problem has been low oil pressure at hot idle (<5 psi with a gauge installed). While I suspect either an eronous reading on the gauge, the nut on the pickup tube to pump is leaking, I removed both valve covers and observed at hot idle a river of oil flowing out of the rockers and along the bottom of the head and draining down the end holes on the drivers side. The passenger side, however, was flowing much less oil. I'll say less than half the amount of the drivers side. I thought of an old trick Ford FE owners did ( I was one of those), you restrict the oil passage up thru the rocker shaft to keep more oil down inside the internals of the motor. I removed the rocker shaft on my 312 on the drivers side, made a sleeve and inserted it into the oil hole that feeds the third rocker stand. Now my oil pressure is up at least 10 psi and about the same amount of oil is flowing on each side. I'll include pictures, unfortunately I was so anxious to try it out I didn't photograph the actual sleeve but I did draw a picture and will show what I made the sleeve out of. It was a cement wall anchor that I cut and filed then bent the top at an angle to fit nicely under the rocker stand. I did have to tighten the two valves down slightly as it slightly raised the height of the rocker stand (only a fraction). The sleeve is 1/4 in and the inside hole of the sleeve is 3/16 inch. Hey, maybe crude but it worked.

|

|

By PF Arcand - 11 Years Ago

|

Rick: As Charlie points out, without documentation the term "rebuilt" can mean just about anything, from a part job which maybe didn't include new cam bearings, to a full out figment of the sellers imagination. And it's quite possible you have a cross drilled cam & or the cam bearing wasn't lined up properly. Try turning the engine in small increments to see if you have any success getting oil or air thru. If the engine looks very clean, it's hard to say what the problem may be. Possibly one of our engine gurus may have other suggestions, short of a total tear down.. Good luck.

S Rod: You need to fix that leaking pump to pan pipe connection. According to a pump rebuilders tag I have here, the pump seal can easily be installed incorrectly & will be damaged & not seal properly. Get a new seal and install it carefully so as to not damage it! Your other fixes for low psi are not likely to be effective until that is fixed...

|

|

By Barry L - 11 Years Ago

|

|

Paul, I hope you meant small "increments".....the other would be messy. Barry L

|

|

By Doug T - 11 Years Ago

|

Assuming that the engine was cleaned inside (especially the oil hole from the cam bearing to the head surface of the block) before re assembly you might have a serious problem. There are three holes in center cam bearing that must be lined up with 3 holes in the block. The other cam bearings only need the supply hole in the block lined up and it doesn't matter which hole in the bearing it is. But if the rebuilder did not pay attention to this on the center cam bearing it is possible to line up the block supply hole to one of the 'wrong' holes in the bearing which means no oil gets to one of the banks. Unfortunately there is no easy fix for this, most people would disassemble the engine and replace the center cam bearing in the right orientation.

|

|

By PF Arcand - 11 Years Ago

|

Barry L : Thanks for the correction note.. it wouldn't have smelt good either...

|

|

By Ricks56 - 11 Years Ago

|

Thanks for all the ideas. I'm going on vacation for 2 weeks and when I get back I'm going to try blocking off the oil passage on the side that is oiling. Maybe that will force out anything that may be blocking the dry side. My oil pressure is good, maybe a little too good? It runs around 70 lbs at road speed and drops to about 35 lbs at idle (hot). I'll report back in a couple of weeks.

Rick

|

|

By John Mummert - 11 Years Ago

|

In nearly every case where a new cam has been installed and there is no or little oil to the passenger side the groove in the center cam journal is not deep enough. I've seen this too many times to count. The groove in all new cams is too wide and not deep enough. The only cure is overhead oilers (no longer available) or pull out the cam, put it in a lathe and cut the groove to .035"-.040" deep. Don't make the groove wider as this will only reduce the bearing surface area and cause the bearing to wear faster.

It is possible that the bearings were installed incorrectly but this is an easier fix so hope this is all that is wrong.

|

|

By crownvic55 - 11 Years Ago

|

When I rebuilt my 292 I had the block work and cam bearings installed by a shop that mostly did Chevy race motors. When I assembled motor, I could only get oil to one head. Had to tear down motor again and discovered cam bearing holes didn't line up. Shop owner said nothing he could do since they were the right bearings and I would have to drill the bearing. Went to Bumper to Bumper auto parts and as soon as I told guy at counter he said "the guy put in Chevy cam bearings. Without even looking up part numbers, he walked back and returned with a set of cam bearings. Fixed my problem. Moral of story: don't get machine work on a Y-block done by an egotistical shrub builder and check before assembly- saves gasket sets and labor.

Ben

|

|

By MoonShadow - 11 Years Ago

|

If the shop owner is that arrogant and refuses to listen you should make sure everyone you know is informed. He's probably screwing up a lot of motors. His skill isn't in question as much as his professionalism is.I wouldn't take a lawn mower to him. Chuck

|

|

By crownvic55 - 11 Years Ago

|

|

After building the motor back again and making sure everything was okay, I went back to shop to explain to guy what he did and to try to get my money back for the gasket set I used and the wrong cam bearings he had installed. Shop was closed and the next time I went by building was empty. Guess I wasn't the only one who had a problem with him.

|