|

By 46yblock - 17 Years Ago

|

|

While breaking down a distributor for rebuild, I noticed there was a lot of wear in the centrifugal weight slot and it's post, both sides. Dist. is C3TF. So I took apart another dist., found less wear, and installed the points cam with slot and centfrigal weights on the first unit. Then almost by accident noticed one of the weight's posts that anchors the spring was almost eaten in two from wear received via spring. Looked at the three other weights and two spring anchors were close to breaking in two. Are new weights available for purchase? Are they included in dist. rebuild kits? Both distributors had one relatively thin spring on one weight and a thicker spring on the other. Each of the thicker springs were very sloppy, applying no tension to their weight in the collapsed position. It doesnt seem right?

|

|

By oldcarmark - 17 Years Ago

|

|

If you are interested Autozone sells a rebuilt distributor(application 64 F100 with 292)for $39.00 exchange or $69.00 outright.I have one in my 56,works great.I don't think you could rebuild yours for that price?Regards Mark

|

|

By 46yblock - 17 Years Ago

|

|

Thanks Oldcar, but I want to rebuild this. It is one of those things that I would like to know how to do, and I have an extra new dist. gear on hand. Plus there is at least some chance that their rebuilt dizzy has some of the same issues. Bushings, shaft and plates on this one are in good shape. I discovered the problem by manually advancing the weight mechanism and releasing. There was a jerky return to position, accompanied by an an audible "ting" from one of the springs, which was hanging up on a bur on the weight post it was attached to. With good glasses the cause was clear.

|

|

By GREENBIRD56 - 17 Years Ago

|

|

There are two post '57 flyweight systems - the slotted one you are working on is the earliest. I have only found one of the early distributors in "rebuilt" condition with like new parts - and it was an extremely ancient "NOS". The slotted upper rotor shaft is top left in the photo for those that haven't had one apart ...

I have also seen the worn posts that engage these slots - but don't have a good way to fix them. I do like the bronze bushed weights and generally heavier duty parts of the early version - and have built that style to use in my outfit. Good luck on the rebuild '46 - it may take a stack of donor parts to get a really good finished version.

|

|

By 46yblock - 17 Years Ago

|

Steve, thanks very much for wishing me good luck, because I sure had it  . I went to my retired mechanic's with shaft and advance mechanism in hand to see if he had any tips. I bought his last two NEW centrifugal weights, and a new 10 degree slotted rotor/points cam. He had the parts left over from his Dyno shop which closed 30 years ago. Both of the stock advance rotors I had were 13 degrees. So this dizzy will be going back together soon, and in great condition. Bill has a Sun machine to do the final tune up. . I went to my retired mechanic's with shaft and advance mechanism in hand to see if he had any tips. I bought his last two NEW centrifugal weights, and a new 10 degree slotted rotor/points cam. He had the parts left over from his Dyno shop which closed 30 years ago. Both of the stock advance rotors I had were 13 degrees. So this dizzy will be going back together soon, and in great condition. Bill has a Sun machine to do the final tune up. I asked him about the springs. He said the big heavier spring was a bad idea that Ford came up with. Allowed for very rapid advance due to no tension on the weight, and then limited max. advance to somewhere above 3000 rpm.

|

|

By Doug T - 17 Years Ago

|

|

In addition to wear where you discribe it I have also taken apart a dist with the crimped connection between the slotted plate and the cam very loose with maybe 10 deg of slop. I have also seen the wear in the slots and on the pins of the weights. I really wonder if the rebuilders take all this into account and check and replace these parts. Has anyone disassembled one of these distributors to see how they look inside? With regards to the short light spring and the heavy longer spring this might not have been such a bad idea. As your guy said it gave a rapid advance up 'til the heavy spring started to extend then a more gradual advance. The problem is that it is very hard to develop a curve like that without a lot of dyno time for each carb & cam combo so yeh for most tuners not a great help.

|

|

By 46yblock - 17 Years Ago

|

Doug T (8/3/2008)

In addition to wear where you discribe it I have also taken apart a dist with the crimped connection between the slotted plate and the cam very loose with maybe 10 deg of slop. I have also seen the wear in the slots and on the pins of the weights. I really wonder if the rebuilders take all this into account and check and replace these parts. Has anyone disassembled one of these distributors to see how they look inside? With regards to the short light spring and the heavy longer spring this might not have been such a bad idea. As your guy said it gave a rapid advance up 'til the heavy spring started to extend then a more gradual advance. The problem is that it is very hard to develop a curve like that without a lot of dyno time for each carb & cam combo so yeh for most tuners not a great help. Yes there was a lot of wear in the slots and on the pins. That was what initially worried me. The wear on one pin was .015, and the slot it fit in had a wear of .012, if memory serves. The pins new are .250. "Has anyone disassembled one of these...?" Good question. My feeling is that the same wear issues would be found in an Autozone "rebuilt" dist. I have to say that diving into the mysteries of the distributor has been fun. Having read quite a few distributor posts in the past, I still lacked a lot of understanding regarding what they were talking about.

|

|

By PF Arcand - 17 Years Ago

|

|

Guys; would similar wear as described, in some cases prevent getting a proper Dwell reading? I've reset my points a couple of times but can't get near the factory recommended dwell. This is in a NAPA rebuilt.

|

|

By Hoosier Hurricane - 17 Years Ago

|

|

Paul: The wear of the pin and slots would not cause any problems with dwell. I would say your distributor has a worn cam. I'll bet when you set the points with a feeler gauge, the dwell is too short. That's because the tips of the cam lobes are worn or polished off. John in Selma, IN

|

|

By 46yblock - 17 Years Ago

|

Hoosier Hurricane (8/4/2008)

Paul: The wear of the pin and slots would not cause any problems with dwell. I would say your distributor has a worn cam. I'll bet when you set the points with a feeler gauge, the dwell is too short. That's because the tips of the cam lobes are worn or polished off. John in Selma, IN John, If the dist. cam is worn as you suggest, what would be the best way to set points and dwell? Optimum gap or dwell, or compromise?

|

|

By Hoosier Hurricane - 17 Years Ago

|

|

46: You asked a loaded question. The "best way" would be to replace the cam. However, I don't practice what I preach, on my Ranchero it seems to run better when I set the dwell. Pattern on the 'scope looks better that way too. John

|

|

By pegleg - 17 Years Ago

|

|

Mike, If you can find a better/newer cam...... use it. The points have to open some amount to decrease "sparking" so the coil can charge, the amount of time (dwell) affects the amount of charge also. Which all means the spark will get weaker and you'll lose top end power first. As John said!

|

|

By HT32BSX115 - 17 Years Ago

|

Mike,

You could just eliminate the points/dwell problem by putting a Pertronix kit in it. I did that on my previous 239 and it ran well (until the timing "belt"  jumped a few teeth!!!) It's in that distributor I think I got from you!! (didn't you send me a dist?) jumped a few teeth!!!) It's in that distributor I think I got from you!! (didn't you send me a dist?)

Cheers,

Rick

|

|

By 46yblock - 17 Years Ago

|

|

Hi Rick, Yes the dist. came from me. I think about the Pertronix everynow and then, but also remember I have purchased three of them and they all were toast within 2500 total accumulated miles. One failure was due entirely to me leaving the ignition on. Never found the cause of the other two. The dist. that I was using had some kind of problem in that a regular type rotor was very difficult to fully seat on the shaft. Actually didnt realize that problem until two caps and rotors were eaten up. One of the Pertronix burnouts happened on the road away from home, almost exactly two years ago, with the wife on board. That day it was over 100, and not fun changing out the ignition to points. So it has been points ever since. Mike

|

|

By GREENBIRD56 - 17 Years Ago

|

|

Mike - you can modify one of the slotted upper rotor shafts and install the Ford electronic ignition trigger (reluctor) with a little machine shop work. Send me a PM with an e-mail address and I'll send you the drawing via PDF. Ends up looking like this:

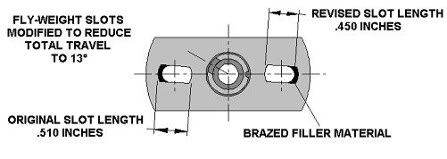

If you braze up the end of the slot you can change the total centrifugal advance by gently using a rat tail file and a caliper. The two upper rotors I came up with both had slots for 15° advance (30° crank) so I shortened the travel so I could use more initial in the curve.

The Ford external ignition box simplifies trouble shooting - just plug in another box. They are cheap and pretty reliable if you take it easy on the amperage they have to switch.

|

|

By 46yblock - 17 Years Ago

|

|

Yeah, I feel ready to try that. Thanks Steve. Mike

|

|

By pegleg - 17 Years Ago

|

|

Mike, I built a Pertonix setup along the lines of what Steve is describing to you. Sent it to Mummert to use when we Dyno'd the engine. He took the Pertronix out, stuck Duraspark parts in it and we hooked it to an MSD6al. I have never touched since except to replace the cap and rotor and wires. It has worked flawlessly for three/ four years now. My F code makes cylinder pressure and will pull well over 6 grand If there was a problem I'd have found I'd have seen it by now. This is the answer with today's technology.

|