|

By peeeot - 4 Years Ago

|

I had a breakdown recently due to a weak spark. I am not sure that I understand what the underlying problem was, and would like to make sure I fixed it for good. Here are the details:

The breakdown consisted of the sudden onset of misfiring, leading to an engine stall. Once stalled, the engine would not fire, but holding the coil wire near a ground while cranking showed a consistent orange spark. The spark would not appear if I opened the gap more than about 1/8”. On the roadside using an engine analyzer and a multimeter, it appeared that I had excessive voltage drop (0.4V) from coil negative to ground, and that most if not all of this drop was through the points themselves. The multimeter I had available would not give a reliable low-ohm reading, so the coil was suspect as well, because I couldn’t verify primary resistance.

I replaced the coil first because that was easier to do. The coil is the internal resistance type and sees 12V on the positive side. The new coil didn’t make any observable difference in spark quality, so next I tried cleaning the points with some 350-grit sandpaper, still trying to avoid a roadside point replacement job. The voltage drop through the points was reduced to more like 0.2V and the car was now running, but I didn’t get more than a couple of miles down the road before I had to pull over again due to heavy misfiring.

This time, I installed the new points, set the dwell to 30, and was able to drive to a safe location nearby without any more trouble. The new points yielded an obvious improvement in spark quality.

The next day, at the safe location, I wanted to be sure primary side resistance was minimized so I tested voltage drop with a different, better multimeter. This time I was showing no drop through the points, but 0.2V through the coil-to-distributor wire. I replaced that, and then both my multimeter and analyzer showed less than 0.1V drop from coil to ground. I drove about 20 miles home without any trouble after that.

Before the trouble appeared, the car ran great. Points and condenser were both new with less than 200 miles on them. It seems that the immediate cause of the breakdown was weak spark caused by bad points, as new points set up with the same dwell as the old ones “healed” the misfiring and hard starting immediately. So, why did the first set of points die so quickly?

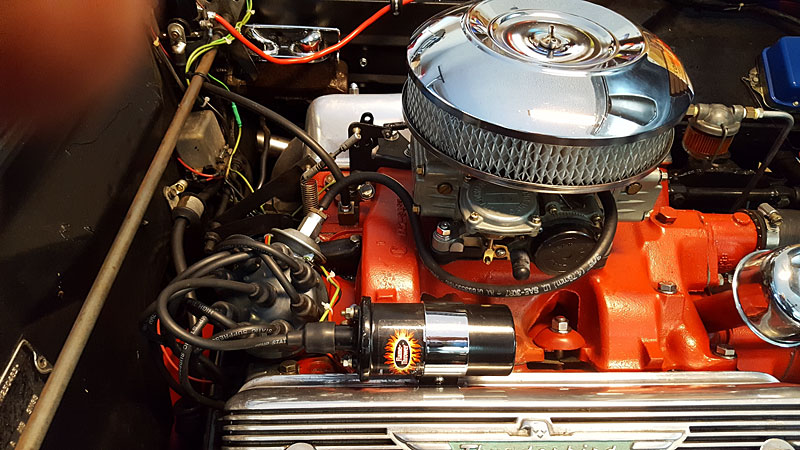

Here are pictures of the “bad”contact points.

|

|

By RB - 4 Years Ago

|

|

Just a guess but excessive voltage to the coil will burn the points contact

|

|

By Deyomatic - 4 Years Ago

|

|

When you cleaned the points, did you recheck the gap? Wondering if the screw may have loosened and the gap was messed up?

|

|

By oldcarmark - 4 Years Ago

|

|

New condensor may be Offshore Junk. Been a lot of bad non USA made Condensors.

|

|

By peeeot - 4 Years Ago

|

I checked the dwell both before and after cleaning the points and it was about 30 degrees. I thought the gap seemed very small but the dwell meter seemed to say it was OK.

Regarding the possibility of a bad condenser: I have read that if the condenser is bad there will be significant arcing evident when the points open. In my case, if it is dark I can see a pinprick blue/white spark at the points when they open. I took that to be normal and indicative of a properly functioning capacitor. Does that sound right?

|

|

By blocky - 4 Years Ago

|

|

are you positive you are using the correct coil??

|

|

By Lord Gaga - 4 Years Ago

|

Condenser is bad

|

|

By Tedster - 4 Years Ago

|

peeeot (12/22/2021)

Regarding the possibility of a bad condenser: I have read that if the condenser is bad there will be significant arcing evident when the points open. In my case, if it is dark I can see a pinprick blue/white spark at the points when they open. I took that to be normal and indicative of a properly functioning capacitor. Does that sound right?

I've wondered about that, having noted a pretty strong spark at the points in testing. But, I've no long experience eyeballing point systems to make a comparison. It later dawned on me that the only way to actually see the points in this situation is with the distributor cap removed, so obviously there's no place else for the spark to go. If you've seen a few, then you'd know what is typical I guess.

Condensers (and ignition coils) are always tested at normal operating temperature. Hot. In the electronics world, a capacitor shorted to ground isn't unusual but I've been told this doesn't typically happen with ignition condensers, due to the high current involved, they tend to go "open" and probably intermittent, as they come up to temperature.

Shorter answer is ignition condensers need to be tested for insulation resistance at around 500 volts DC, the modern digital "capacitor checkers" simply can't do this. Defective condensers can be weeded out with these, but that's only part of the story. A healthy capacitor will charge up and hold high voltage for a very long time, at least a day or two. I noticed this in comparison testing some suitable high voltage modern poly film caps. My stable of NOS or junk box "pulls" appear to pass the high voltage leakage tests cold but they are no longer able to retain voltage for any length of time. In rainy weather or high humidity I bet it would cause trouble, also under severe service.

I don't ordinarily run points any longer but do have a spare points distributor setup w/ tested condenser and spares. This is a weak spot for the DIYer without access to the right test equipment. We tend to think of new ignition parts = good parts, and that isn't true, not with condensers, and we also tend to think of NOS parts = good parts, and that isn't necessarily true either, for different reasons. They are getting older and degrade just sitting on the shelf.

|

|

By peeeot - 4 Years Ago

|

blocky (12/23/2021)

are you positive you are using the correct coil??

I am not positive about the coil. The car was rewired with an EZ mini 12 circuit harness before I bought it. The coil bore no brand identifiers, just a blue can with markings stating that an external resistor was not required and a 4-digit number that doesn't seem to cross-reference with any part numbers I could find. The coil I replaced it with was the closest thing I could find at the local parts store: Carquest EBC1487. I have considered using a stock coil and adding an external resistor so that I could be sure, plus get the 12V starting boost from the solenoid, but as it is I am able to start in freezing weather just fine.

Tedster, when I was cranking and observing the points I had the coil-to-cap wire plugged into the coil and grounded, so the spark did have somewhere to go (if I understood your comment right).

I did buy a spare replacement condenser to install in case of a repeat breakdown. I don't like to think it's 50/50 whether a new condenser will be good, but I have the impression that is a common perception, so maybe that's how it is.

One other variable I wondered about with regard to the points failure was whether I might have over-lubed the point cam. The factory manual calls this out as a possible cause of burned points. To my eye the points and surrounding area look totally clean though.

I drove the car about 75 miles today with no ignition trouble at any time. Perhaps this weekend I'll take another look at the points for signs of premature wear.

|

|

By FORD DEARBORN - 4 Years Ago

|

|

It looks like you probably have a good condenser since the car is back on the road with the same condenser. Since it's a points system, just by design it's designed to run with a resistor in the circuit. The original Ford yellow top coil of the day had a primary resistance of about 1.5 ohms and about that amount again for the resistor. This keeps the current through the points at a level for which they will be happy with for many thousands of miles. That coil you had that stated no resistor required was probably for some form of electronic ignition system. You didn't stae what the primary resistance of the coil was but it may have been low enough to cause excessive current/heat for a points ignition. Just a thoght - hope it helps.............

|

|

By Lord Gaga - 4 Years Ago

|

I use a .22 MFD (double check your condenser's specs.) CAPACITOR from a electronics supply. Much more robust than the junk condensers that are only manufactured as an obsolete afterthought now.

|

|

By 312YBlock - 4 Years Ago

|

|

I had a similar experience, same symptoms. When cold all was well, when hot all was hell, backfiring on steroids. I was 12v with new resister and condenser. Long story short the ballast resistor was replaced with and old one and the car ran fine for a couple hundred miles when the miss and backfiring began again, this time it was the condenser. I was now in Memphis, Tennessee and drove back to NY with no further incident. I’m now all electronic ignition and my blood pressure has returned to normal.

|

|

By Tazx100 - 4 Years Ago

|

I am definitely not an expert in this area, I had the same issue back in the day running dirt track, I had 12 volts going to the points and they didnt last long I was advised to put a resistor that brought the voltage down to 6 volts to the points and that fixed it.

|

|

By Tedster - 4 Years Ago

|

I don't know if it's the voltage so much as the current (heat) that is the issue here. Maybe arcing becomes a factor, I don't know. Excessive heat will cause coil trouble. He mentioned replacing with an "internal resistance" coil, but the details matter. I assumed it was a standard ignition points coil of approx. 1.5 ohm primary winding. Coupled with the ign RUN ballast of approx. 1.5 ohms, this will keep the total ampere flow through the ignition system within spec with the engine running.

It's probably a good idea to check "point resistance", between battery negative post and the movable points plate in the distributor. Depending on the distributor design various intermittent ground defects can cause trouble, too. Frayed primary wiring from coil to distributor, or the bare copper stranded strap that grounds the points plate to the distributor housing might be missing or "not installed".

|

|

By Tedster - 4 Years Ago

|

Lord Gaga (12/24/2021)

I use a .22 MFD (double check your condenser's specs.) CAPACITOR from a electronics supply. Much more robust than the junk condensers that are only manufactured as an obsolete afterthought now.

Which one do you use? I have several in my kit for radio & stereo work. I tested some Sprague "Orange Drop" 715, these are large 600 volt 0.22uF film capacitors. The thin metalized film type are said not to work in this application. The orange drops seem to look great on a scope in the garage but I didn't try them on a road trip or anything like that. They have solid leads though, so they would need protection from vibration or they will work harden and break, I expect.

|

|

By peeeot - 4 Years Ago

|

312YBlock (12/24/2021)

I had a similar experience, same symptoms. When cold all was well, when hot all was hell, backfiring on steroids. I was 12v with new resister and condenser. Long story short the ballast resistor was replaced with and old one and the car ran fine for a couple hundred miles when the miss and backfiring began again, this time it was the condenser. I was now in Memphis, Tennessee and drove back to NY with no further incident. I’m now all electronic ignition and my blood pressure has returned to normal.

I know what you mean about blood pressure! :-D When I was on the roadside dealing with this I was really reconsidering going with Pertronix. I still might eventually make that switch.

I just did a quick check and found the following, with drivetrain cold and ambient temperature of about 55*F: coil primary resistance = 3.0 ohms, secondary resistance = 9560 ohms, voltage drop from coil negative to battery negative, 0.145V (key on points closed). My distributor, points, and condenser are 1959-spec. The coil internal resistance is very close to the '59 cumulative resistance of ballast + coil, the range of which is 2.7-2.94 ohms per the factory service manual. The '59 stock coil is supposed to have 8000-8800 ohms secondary resistance, so my current coil exceeds that. The manual also expects a coil negative to ground voltage drop not exceeding 0.1V.

I'll also note that the distributor was disassembled and thoroughly cleaned before installation just a couple of hundred miles ago, and that the breaker plate ground wire was replaced at that time as well as the coil to distributor terminal wire. The only piece of primary wiring I haven't replaced yet is the distributor terminal to points terminal wire, but it hasn't shown any voltage drop any time I have checked it. If trouble persists without an obvious culprit, I will replace it.

My current plan is to keep driving and just periodically check the coil to ground voltage drop for signs that it is increasing. I will of course have diagnostic tools and spare parts on hand! Do you think the differences in coil spec would have significant impacts on point life or ignition performance?

|

|

By Florida_Phil - 4 Years Ago

|

Back in the day, we never worried about these things. We ran down to the local auto parts store, bought new points and a condenser and rode down the road. These days, buying points and condenser for a Y-Block is like playing a slot machine with a 50% house edge. Buy a Pertronix unit and the matching Pertronix coil and forget about it. My TBird engine starts first time every time and never misfires, stalls or leaves me on the side of the road. I do miss waiting around for the AAA tow truck driver..... :>

|

|

By Dave V - 4 Years Ago

|

|

There is a guy (Jon G) on www.stovebolt.com which is old GM trucks that developed a capacitor that replace condensors in most any situation. Fits in just about any distributor or can be mounted externally. Search the Forum section for "The electrical bay" section and browse for "Aftermarket condenser". Looks to be a pretty good idea.

|

|

By DryLakesRacer - 4 Years Ago

|

|

The points to me look like too high of a voltage but they were not blue like others I have seen not running a ballast resistor. I suffered twice with point/condenser problems before going electronic. Many to choose from and I haven’t changed or had to clean spark plugs for 8 years. Timing also never moves.

|

|

By Tedster - 4 Years Ago

|

Honestly I can't see anything wrong with those point faces in the picture?

I ran points for a long time, thousands of miles and they always looked something like that. Like somebody mentioned, nobody paid any attention to this stuff years ago. We just drove.

|

|

By 2721955meteor - 4 Years Ago

|

|

I removed the ford duraspark,relaced with used dist(points)and sprayed some thin rust remover.. started but run poorly. pulled dist found the points not working due to the spray,dismant dist clean and am installing petronixl system. work still in progresses vac advance wear buttons missing from movable plate to vac advance unit. appears points very sensitive tomtits trapped re lube or cleaning

|

|

By Lord Gaga - 4 Years Ago

|

What I used was an IC PPB 1K VDC .22uF 10% FD50 mounted externally. I bet the Orange Drops would work fine and fit under the cap.mounted securely. You can carry a spare stock type condenser with a screwdriver and a wrench just in case.  Tedster (12/24/2021)

Lord Gaga (12/24/2021)

I use a .22 MFD (double check your condenser's specs.) CAPACITOR from a electronics supply. Much more robust than the junk condensers that are only manufactured as an obsolete afterthought now. Which one do you use? I have several in my kit for radio & stereo work. I tested some Sprague "Orange Drop" 715, these are large 600 volt 0.22uF film capacitors. The thin metalized film type are said not to work in this application. The orange drops seem to look great on a scope in the garage but I didn't try them on a road trip or anything like that. They have solid leads though, so they would need protection from vibration or they will work harden and break, I expect.

|

|

By peeeot - 3 Years Ago

|

After several months and hundreds of trouble-free miles, this problem has emerged again. Exact same story as before. This time the ignition went from normal to dead-in-the-water in about 10 seconds idling at a stoplight. Spark was weak and resistance through the points was excessive (0.4-0.5V). I used a nail file to try to bring the points back but I could only get the car to run for a minute or two before it quit again. As before, a new set of points instantly cured the problem.

2 new wrinkles to the situation:

1. this time I installed my new spare condenser

2. I only got about 100 miles in before the same symptoms appeared again (both failures occurred today!). This time it quit a few blocks from my house. I pushed it into a street side parking spot and walked home.

I don’t understand what’s killing the points, and why sanding/filing them doesn’t bring them back. 2 new condensers, same outcome.

Part of me wants to make the points work, but the rest of me is ready to throw in the towel and go Pertronix.

|

|

By DryLakesRacer - 3 Years Ago

|

|

Sorry to hear of your troubles. After 2 Chinese condenser failures I installed a Pertronix II. I used their coil and kept the ballast resistor. I have never ever used a coil with an internal resistor and converted many 6 volt cars to 12 volts. Pertronix told me on the phone either way with the ballast resistor use, there was only less high voltage going to the plugs. I choose to have the lower voltage because I figured the coil would be cooler and engine is only 8.1 stock anyway. I have never had any failure or even an engine miss. I’ve cleaned the inside of the cap once in 10 years and that’s it.. good luck.

|

|

By Robs36Ford - 3 Years Ago

|

What is the min and max voltage of the voltage regulator ?

Too high will burn point and fail Condesor.

|

|

By 2721955meteor - 3 Years Ago

|

|

just go with the dura spark,easey to inst and works. I was hard to convince, but gave in and should have listened would have saved some gray hair

|

|

By Saltshaker - 3 Years Ago

|

peeeot,

This is my first time posting on the forum. Hope this might help.

Your problem may be with the ballast resistor. Did you have one on the coils that failed?

Depending on the coil you are using, the ballast resistor (if you had one) needs to be compatible with the coil.

The original 56 Ford coil primary winding should be around 1.5 ohms at room temperature. The ballast resistor for the 56 should be about 1.5 ohms, giving a total primary circuit resistance of 3 ohms.

So what happens if they aren’t? You will eventually burn up your coil and possibly your points without one because at low RPM the dwell time, increases causing more current to travel through the primary coil and points. The fix is to install a ballast resistor, in this case a 1.5 ohm version for a total of 3 ohms. This is what the system was designed to use.

If you don’t have a ballast resistor you might want to get one, and also make sure you’re coil primary winding is 1.5 ohms plus or minus a quarter ohm.

Another solution is to use one of “Internal Ballast” coils. They don’t really have an internal ballast they just have a somewhat lower ohm primary winding and you can get by without a ballast resistor.

I know some people insist that they do have a ballast, but if that was true how do you hook up a bypass cold starting circuit? There is no third terminal. Also, there is the heat problem. An internal ballast would heat up the coil which is already on the edge of being a barbecue grill. Better to have the heat on the outside.

Some British coils did have three terminals with internal ballasts, but the Lucas Company who forever ruined the British automotive electrical industry's reputation made them, and anything they built was sketchy to start with.

Don

I checked the Carquest EBC1487 coil and it's primary resistance is .3 to 1.0 ohms.

|

|

By peeeot - 3 Years Ago

|

Robs36ford, the car has a Delco 12SI alternator (78A) and voltage has been observed in the 13.5-14.6 range.

Saltshaker, I have seen the same specs posted for the EBC1487 but I don’t know why because they are totally wrong. The coil has an internal resistor and actual primary resistance is 3.0 ohms. You are correct that the “extra” 1.5 ohms of resistance cannot be bypassed, but I have found using the 12v supply during cranking from the starter solenoid still helps.

I found this article elsewhere regarding condenser failure: http://www.nonlintec.com/sprite/cap_failure/

I think Lord Gaga has the right idea about sourcing a modern capacitor that is up to the task as opposed to the mixed-bag indifferent-quality parts that are readily available. All that being said, since distributor access is so unpleasant on my ‘54 (especially in a roadside emergency situation) I have ordered Pertronix 1281 and will carry my best set of points and a condenser as “just in case” parts.

|

|

By peeeot - 3 Years Ago

|

|

Does anyone know whether excessive resistance in the spark plug wires could contribute to breakdown at the points or condenser?

|

|

By FORD DEARBORN - 3 Years Ago

|

|

As secondary resistance increases, the voltage necessary to overcome it must also increase. That in itself will add stress to the secondary and primary circuits. I've never really thought of the added stress as detrimental to the points or condenser. An open sparkplug wire, however, will drive up the induced voltage to it's max and that has been known to cause coil damage. It appears most all the points/condenser issues, IMHO, are related to poor quality condensers. Use a 1KV rated capacitor as stated by Lord Gaga. If I remember correctly, there's quite a surge at the moment the points open as seen on an oscilloscope. It's the condenser that takes this surge by momentarily taking the + end of the secondary winding in the coil to ground to provide a rapid collapse of the field. I've gotten more than one good jolt from rapidly simulating the points with a wire in my bare fingers. That surge on the condenser when the points open can be up to 200V or more. I often wonder if the present condensers now on the market are only good for about 12V? or somewhere close to that. Besides mechanical wear, 2 things cause points to go bad, 1) excessive arcing caused by a marginal condenser and 2) excessive current possibly from not enough resistance in the primary circuit - the resistor itself, or a coil not matched for points/condenser. Hard question to answer, hope this makes some sense.

|

|

By Tedster - 3 Years Ago

|

Voltage rating is only part of the story when it comes to capacitors. Ignition Service is rough duty. It isn't that they are a high-tech product, after all they've been around for 100 years now, but apparently modern manufacturers can't build them to a low price point any longer. Not in the small, compact package used when mounted internally inside a distributor anyway. The other criterion other than voltage rating is known as Dv or rise time. Kind of related to current, I expect.

So what you have to look at when actually choosing a capacitor for points & condenser applications is whether it can meet the ignition specs. There are very compact yet high voltage capacitors available made by metal vapor deposition, these are tempting to use because they will so easily fit inside distributors, but they simply won't hold up. Suitable capacitors tend to be a little on the chunky side, physically speaking. There's nothing that says it must be mounted inside the distributor, btw.

|

|

By peeeot - 3 Years Ago

|

Thank you for your detailed responses! I understood that increased resistance would demand more voltage on the secondary side, but the nuances of the current/voltage/magnetic fields/oscillation on the primary side are pretty nebulous to me so I wasn’t sure whether the primary side would also see increased current or voltage in some way. I have found that some of my plug wires are over 32k ohms, and even the coil to cap wire is over 12k. Those resistances, along with the “E” type rotor on the distributor, must be working the ignition system harder than intended.

Before I install the pertronix I’m going to see if there is any evident change in spark quality from just changing the plug wires, just out of curiousity.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

Those sparkplug wire resistances sound high to me. I just went out in the garage and measured a couple new spiral wound sparkplug wires. They averaged about 3760 ohms per foot. If I can remember correctly, even the old carbon wires were not as high of a resistance as you reported, maybe others will chime in. When you get the new sparkplug wires it will be interesting to see what they measure. Rotor and sparkplug gap is what the voltage must overcome. I don't know off hand what the size hole is in a Ford rotor but if you can find something that size to slip the rotor onto, a dial indicator can be used to compare the tip to that of a known good rotor. I recently found the rotor in my distributor to be eroded by .010" but that's another story for a new thread.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

I should of added that the actual resistance with an ohm meter with its 3 or 4 volts across the probes is not a true indication of wire condition but the resistance I stated above is typical of what I'm used to seeing. The resistance of the core is designed to reduce RMI and RFI interference. The actual energy passes over the core (skin effect) rather than through the spiral core. Someone else with more knowledge than I on this subject could explain this much better.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

https://www.magnecor.com/magnecor1/main.htm Hopefully I did this correctly. If the link opens, on the left side of the screen click on "THE TRUTH A BOUT IGNITION WIRE CONDUCTORS". It's a long article by Magnacore but very good..........................

|

|

By charliemccraney - 3 Years Ago

|

Sortof off topic.

I've started checking plug wire resistance when new and writing it down. This helps to confirm that the new wires have no problems but also provides a baseline for future trouble shooting. Resistance per foot can vary wildly from one wire tech to another so knowing this from the start can be a big help.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

Charlie, can you fix my posted link so it will open? I think this article will explain some of what you mentioned above along with what is important, what is not and why. Thanks.............

|

|

By charliemccraney - 3 Years Ago

|

|

Fixed it. There was an extra space at the end.

|

|

By peeeot - 3 Years Ago

|

Interesting reading from Magnecor. It is refreshing to read what appears to be a transparent, no-nonsense representation of the product and its appropriate application.

I measured the resistances of my new wire set and it looks like they are about 4500 ohms per foot. This is definitely an improvement over what I had on there, which was probably deteriorated from age, oil, antifreeze, temperature, etc.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

Looks like things are headed in the right direction. When you have the new Pertronix unit and coil installed, I think you will put your ignition issues to bed for good. Thanks Charlie for fixing the link. I'll probably be an analog person for ever...........

|

|

By peeeot - 3 Years Ago

|

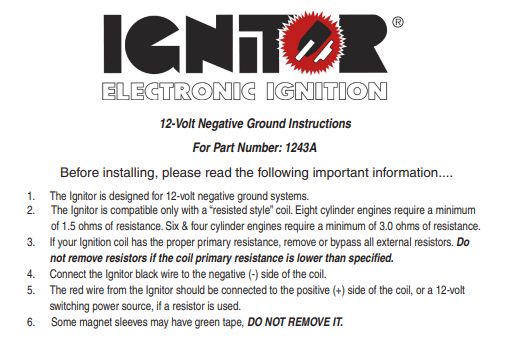

I have been trying to decide whether to continue to use the internal-resistor coil as I make the switch to pertronix, or instead to swap in one of my other external-resistance coils. The instructions state that I can use any coil with an internal resistance of 1.5-3.5 ohms, and/or that total primary resistance including external resistor is not to exceed 3.5 ohms. My internally resisted coil is in the accepted range, but so are the 1.5-ohm point-type coils I have. I suspect it will work fine with either.

Curiosity has led me to try to determine what the intended application was for the internally resisted coil. The only thing I’ve been able to nail it down to is a late 60s Opel Kadett! In fact, the only factory applications I’ve found for internally-resisted coils are 4-cyl European cars.

I have 3 such coils in my possession. All 3 have approximately 3.0 ohms primary and 9500 ohms secondary. I have 4 external-resistor coils, including an original mustard top, all of which have about 1.5 ohms primary and 7700-8700 ohms secondary. I know nothing about the performance properties of these coils besides their resistances. It has me wondering whether my points troubles were caused by incompatibility between the coil and condensers, knowing the coil was probably intended for a 4-cyl and the condenser for an 8-cyl. Any ideas whether this could be the case?

Regardless, I’m probably going to go with one of my 1.5 ohm coils and not use a resistor with pertronix.

|

|

By DryLakesRacer - 3 Years Ago

|

|

I don’t believe the condensers of years past would know the difference other than the possibility that 1/2 the operations would keep it cooler on a 4 to an 8 and 1/3 on a 6 to an 8. In all the years owning a points automobile engine I only had one condenser fail and it was a combo unit it on a 1973 Monte Carlo. As stated prior I have used a Pertronics coil AND a stock 56 ballast resistor for 9 years without fail.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

More than likely you will be ok using the onboard resistor, it that's what you wish to do, only IF the coil isn't too low in resistance. If the coil is one with a low primary resistance, then the onboard resistor will run too hot. For example, the Ford yellow top coil should be used with a 1.5 ohm resistor as the two components establish the correct total circuit resistance. By eliminating the resistor, a yellow top coil would run much too hot. Pertronix makes a 1.5 ohm coil, among others, which would be totally compatible with the Pertronix unit in the distributor and can run with no resistor. By eliminating the resistor, the spark energy will be greatly increased and the Pertronix coil is designed and proven to function in this combination. Trying to mix and match components could very well cause either the coil or resistor to run too hot and fail. Also, I agree with the above post that a condenser doesn't know weather it's used with a 4, 6 or 8 cylinder engine. You probably have one of the numerous poor quality condensers now available.

|

|

By peeeot - 3 Years Ago

|

|

Ford Dearborn, are you saying that a conventional (not pertronix-brand) coil, such as the stock Ford yellow-top, will not work with the pertronix ignitor module unless the system has a resistor? I have the understanding that any coil having 1.5-3.5 ohms primary resistance will work with the pertronix.

|

|

By 57RancheroJim - 3 Years Ago

|

I have one engine running a stock mustard top coil with a pertronix. You need the external ballast resister to cut the voltage down from 12V to about 8V as the factory designed it or the coil will overheat and burn out. The Pertronix is best run on 12V and thats why they recommend splicing the hot ( RED ) wire for the unit into the 12V line before the resistor.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

I've always thought of the Pertronix as a switching device like a set of points. The yellow-top coil is not truly a 12V coil. It operates at 6-7 volts accomplished by the additional 1.5 ohm resistor. When cranking, the resistor is bypassed for ease of starting only. Eliminating the 6V drop across the resistor would put full battery voltage across the coil when the points close and since the Pertronix is taking the place of the points, it should have the same effect on the circuit. This would also double the current and that will produce a very rapid rise time for greater saturation producing a much hotter spark - the beauty of Pertronix. The current of the yellow top coil is kept in check by the 1.5 ohm resistor. With out is, the current doubles. So, the 1.5 ohm coil would work if the resistor is kept in the circuit, IMO. If the Pertronix has a current limiting feature at some threshold then I'm not aware of it and besides, that would defeat the purpose of developing a modern hot ignition. The current is not straight forward because there are other things going on like dwell time and inductance. Never the less, the book states 4.3 amps with the engine stopped and 2.5 amps idling in the primary circuit. Without the resistor, this current would effectively double but not for long. Maybe a Pertronix instruction sheet would address this?

|

|

By FORD DEARBORN - 3 Years Ago

|

|

57RancheroJim you pulled the trigger before I did. Well said in a few words.............

|

|

By 57RancheroJim - 3 Years Ago

|

FORD DEARBORN

You provide great technical info which is right on, I try to keep mine short and simple because I hate typing.

I always wondered why they never built a true 12V coil, maybe they has so many 6V coils in stock it was cheaper to just add a resistor LOL

|

|

By DryLakesRacer - 3 Years Ago

|

Manufacturers needed to lower the voltage and added the resister because 12-14.5 volts burned up the points! The first car I added 12 volts and a V8 to was a 53 GM car and I burned up the points in 5 miles. Because of coil heat I bought the Pertronix coil and kept the stock ballast resister after a call to them. They said either way and like others have said not quite as high of a spark under driving circumstances but with the bypass a hotter starting spark just like the stock points set up. It’s choice like they said.

To me the advantage was no more condenser failures or point maintenance.

|

|

By peeeot - 3 Years Ago

|

Interesting. So, reading between the lines, you (both) are implying that the 1.5 ohm coil marketed by Pertronix is designed for the doubled current afforded by losing the resistor (total primary resistance of 1.5 instead of 3.0) so both it and the Ignitor switching module can handle it. Meanwhile, stock point-type coils are not designed for the extra current and would consequently live shortened lives, even though the ignitor itself would still be fine. Am I understanding you correctly?

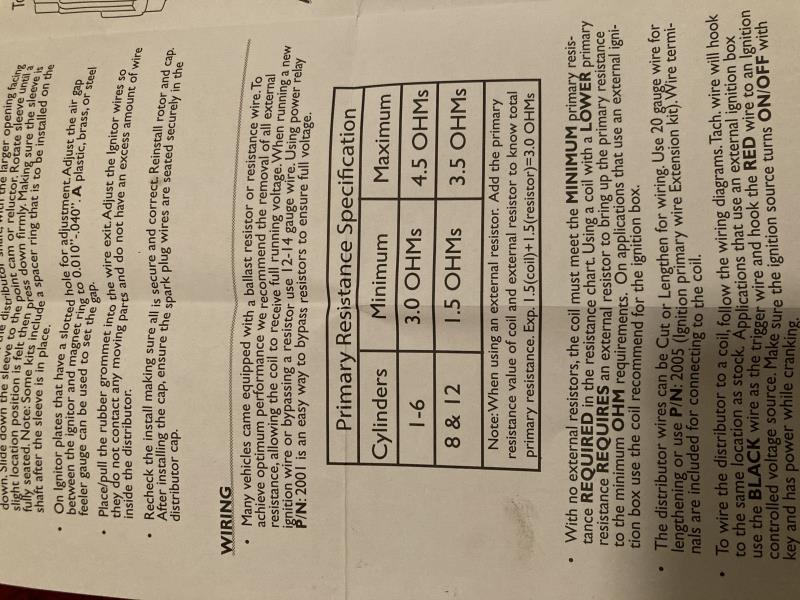

Where my confusion comes in is that the guidance from the instructions seems to go against that. Here is a photo of the instructions included with my 1281 kit.  As I read it, any coil or coil+resistor combo is fine provided that, for a V8, total primary resistance is 1.5-3.5 ohms and 12V is supplied to the ignitor module itself. As I read it, any coil or coil+resistor combo is fine provided that, for a V8, total primary resistance is 1.5-3.5 ohms and 12V is supplied to the ignitor module itself.

Seems like using an internally-resisted coil, or a stock coil+resistor, would be “safer” but may reduce spark energy as mentioned above. For my street-driven car I’m not sure that I’d ever know the difference. I just figured if Pertronix recommends not using a resistor, I’d go with their recommendation.

DryLakes, you posted while I was writing. It does seem like a matter of preference as you say, and like you I am just looking for reduced maintenance and reliable operation. I hope I can be one to say “ten years with no trouble!”

|

|

By FORD DEARBORN - 3 Years Ago

|

|

I think where Pertronix may be going with the 1.5 ohm minimum requirement is to protect the Pertronix device itself. After all, it too has it's current handling limitations. They are concerned with warranty issues. It's up to the end user to figure out what electrical values any particular coil needs. Yes, the 1.5 ohm coil marketed by Pertronix IS designed for the increased current and I personally have run that coil with no resistor and no issues for several years as other folks have done. If you try coils of unknown pedigree or specifications you may be asking for roadside trouble. Yes, any coil designed to be used with a resistor must be used accordantly. It almost always states on such coil: USE WITH EXTERNAL RESISTOR or something like that. So called 12V coils are 7 V coils because during cranking, the working voltage at the coil is still 7 +- volts when the resistor is bypassed by the starter solenoid so will produce full spark energy during the cranking event. I have, years ago, mocked up an entire ignition system to run on my distributor machine. Long interesting story shortened, by simply placing a jumper across the resistor, the sound and intensity increase of the spark was very obvious along with the fragrance of ozone. IMO, the best and safest setup is the 1.5 ohm Pertronis coil. That combo will produce energy far beyond any stock system with resistor and that has to be good for better cleaner combustion/fuel burn and all that.

|

|

By Saltshaker - 3 Years Ago

|

Here's a bit of conflicting info from Pertronix that came from a current document on their website. This is not the first time I have seen them doing this. Some may be caused by dated material.

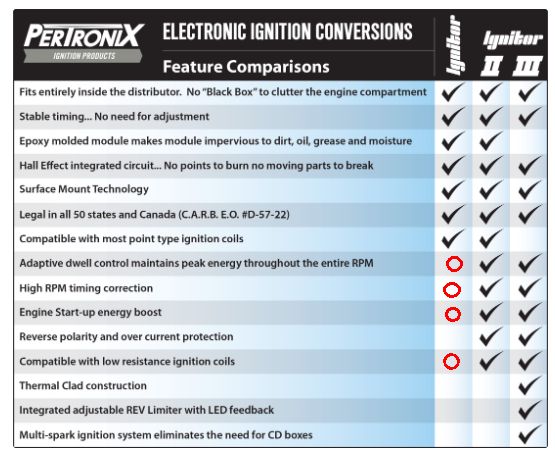

I think some of the uncertainty in whether to use or not use a ballast resistor comes from Pertronix selling three different versions of Ignitors, a standard Ignitor (formerly called called Ignitor I), an Ignitor II, and a Ignitor III. Pic 1. Note that one of the main differences is that Ignitor II and III have adaptive dwell. That's really not a true statement. It should say have adaptive dwell TIME. Dwell angle can't be changed, dwell time is constantly changing with engine RPM.

At idle the dwell time is long and can overheat the coil. Speed it up and dwell time is extremely short, to the point of not fully saturating the coil with current. That, and point bounce will never allow a points system to be used for racing without doing major modifications such as dual points and increased point spring tension.

So, go fast and the ignition misfires because of short dwell time. Go slow, and burn up the coil because of long dwell time.

Pertronix II and III have adaptive dwell time control so using a ballast with them is not needed. Pertronix I does not, so there must be a balance between the ballast resistor and primary winding in the coil. Here is Pertronix's instructions on that. Pic 2

I think you have the right take on it. An 8 cylinder can use a 1.5 ohm or a 3.0 ohm coil without a ballast, but if it's not a performance issue use the 1.5  with a ballast. with a ballast.

|

|

By Tedster - 3 Years Ago

|

Pertronix Ignitor will handle a pretty wide range of voltages. It's nothing more than a Hall effect sensor/switch. What it can't handle though, is excessive current (heat).

This is why the total primary circuit resistance figure is important. I wouldn't say Pertronix info is contradictory, the problem is there are many different combinations that can be put together. People very often order the wrong parts. An ultra low 0.2 ohm resistance ignition coil paired with the original recipe series I ignitor, well, it isn't going to last very long.

You can figure it out for yourself using Ohm's Law.

|