|

By NewPunkRKR - 16 Years Ago

|

|

I'd like to get a blue thunder intake, but as long as I'm going to get rid of the stock I was thinking maybe I could take a stab at modifying it first and save the $ for other parts. I've never done anything like this before, but it seems worth a shot. I have access to a vertical mill, but was wondering if anyone had some detailed information about what should be cut / changed to improve it's performance. Is it worth the attempt? If mummert is coming out with a new intake that is better than that blue thunder, than this might buy me some time while that is developed. I just don't want to wreck my intake and then be out. all help appreciated. - John

|

|

By 46yblock - 16 Years Ago

|

|

Speedway has a good and interesting 5 hour set of DVDs that covers match porting of intakes http://www.speedwaymotors.com/HEADS-PORTING-and-VALVE-TRAINS-3-DVD-SET,7587.html and a lot of other worthwhile information. I have the material together to try match porting a set of heads and intake myself, but suggest practicing on some expendible parts first. To match port the intake alone, and not the heads, wouldnt do any good.

|

|

By NewPunkRKR - 16 Years Ago

|

|

I don't want to mess with the heads. That's beyond my ability and that would be real bad if I trashed a good set of heads. Specifically w/ the intake, I was thinking of milling the top. Opening up the holes to a similar pattern as the blue thunder. does anyone have measurements? any benefit to this? - thumbs up or down?

|

|

By Hoosier Hurricane - 16 Years Ago

|

|

Slot the holes front to back, but do NOT remove the front-to-back dividing wall between the left and right throttle bores. Won't work right. Been there and done that.

|

|

By charliemccraney - 16 Years Ago

|

I found it!

http://www.y-blocksforever.com/forums/Topic11190-3-1.aspx

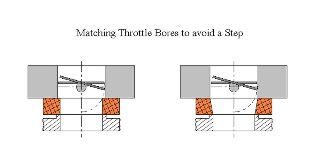

In addition to slotting the manifold, open the throttle bore radius to mach the carb or spacer. You don't want a step in there.

|

|

By pcmenten - 16 Years Ago

|

It's interesting to hear the recommendation about slotting the primaries to the secondaries. I ended up with two iron 4bbl intakes for the small valve (2.09) Clevelands. One has four holes, the other has the two slots. I was going to use the four hole intake, thinking that the slotted intake was inferior.

Does anybody know why the slotted intakes work better?

|

|

By NewPunkRKR - 16 Years Ago

|

|

Excellent - Thanks for the link. I'll take a stab at it and post some feedback/pics when i'm done.

|

|

By Doug T - 16 Years Ago

|

This is what you need to do. Slot the holes together. Then look into the right side hole no matter which end you look from and you will see an obvious restriction where the passage on the right side dives under the cross runner. Grind on this to open it out. The left side is not so restricted and doesn't need much. Radius the holes where they start at the flange so that the flow does not have to go over the sharp edges left over when the holes were machined. This pic shows a manifold that has the grinding finished but it has not cleaned up by blasting. After blasting fill the surface of the flange including the space between the slots with an epoxy glue mixed with the iron filings that you have saved from the grinding. Grinding is not the right word because I don't use abrasive stones for any of this, I do it all with carbide tools and a high speed, electric die grinder. Level the hardened glue/iron mix with a file. I also plug the hot air tube with a 5/16 bolt on both sides and I don't run the heat in the exhaust plenum, However this means things are slooooow to warm up! I like a 4 hole spacer for slightly crisper throttle responce. I used a manifold modified like this before the BlueThunder was available and had my engine dyno tested. This manifold modification supported over 325 hp on pump gas normally asperated, so it does work.

|

|

By pegleg - 16 Years Ago

|

|

Paul, They don't always. Combination of plenum volume and mixture velocity issues decide that. In many cases people add HP with 4 hole spacers under the carb. My Windsor powered Ranger being one. It liked the 4 hole better on the original Wieand manifold. With the Edelbrock that's now on it, the reverse is true. (?)

|

|

By rexbd - 16 Years Ago

|

|

Sorry for being dense. What do you mean by "After blasting fill the surface of the flange including the space between the slots with an epoxy glue mixed with the iron filings that you have saved from the grinding" Are you trying to create a smooth surface on the top of the flange

|

|

By pegleg - 16 Years Ago

|

Rxbird: yes

|

|

By GREENBIRD56 - 16 Years Ago

|

|

Make sure your spacer doesn't interfere with air flow out of the back side of the primary. The slots prevent this from biting you with a SLOTTED and divided spacer - but a four hole spacer with too small of a bore will cause some disruptions of the air flow.

|

|

By Doug T - 16 Years Ago

|

|

Expanding slightly on Frank and Steve's responces, yes you want the top flange of the manifold flat. As originally delivered from Ford the spacer sealed on the rings around the 4 holes as shown in Steve's illustration. But these have been ground away so if you don't fill and flatten the flange mating surface the seal will have to be made at the outside edges. Also you will have those recessess connected to the manifold plenum which might have some weird effect engine runnning. BTW the epoxy glue/iron filings have lasted for 10 years on the first one I did. Besides checking the Throttle opening as Steve suggests you should also be sure that the spacer you use will seal to the carb and manifold. I am using an aftermarket 1" high 4 hole on my truck (which might be too high for a '57 Pass car) that has some recesses in the bottom. These recesses nearly overlap the manifold and if they did there would be a severe vacuum leak so check that also. If you are using the stock Ford 1/2" 4 hole you will be OK.

|

|

By NewPunkRKR - 16 Years Ago

|

|

Is it better to use a slotted spacer to match the intake, or the 4 hole, or does it not matter? Also, the blue thunder has a notch out of the center divider, What advantage would that provide? Is it not worth trying to replicate that? - John

|

|

By GREENBIRD56 - 16 Years Ago

|

|

This is what the Blue Thunder looks like for those who are wondering ...... I have seen a "B" manifold milled flat and the mounting face slotted just like it. I think the rectangular crossover slot is an attempt to provide "balanced" manifold vacuum - but I don't think you have to have it for the system to perform well.

|

|

By Doug T - 16 Years Ago

|

|

Re 4 hole vs wide open spacer, any abrupt change in cross sectional area of a flow stream causes turbulance. Under the 4 hole spacer or under the carb itself with a single hole spacer there is an abrupt increase in flow area between the holes. This is the space between the holes and there is undoubtedly an eddy current swrilling in this area. Note that when you are running on the front two bbls of the carb this eddy will be up under the carb with a wide open spacer and under the spacer with a 4 hole. However with the four hole spacer the air is pulled back to the rear of the engine over the sharp edge of the spacer at part throttle. With a single hole spacer the eddy fills the whole spacer. This is probably why a 4 hole spacer gives a crisper response, the flow is "organized" to look more like the full throttle flow pattern. The engine doesn't need to "get rid" of the eddy that exists under the secondarys of a single hole spacer/carb setup. But once the flows are established from the primarys and secondarys at wide open throttle, the single hole is said to give stronger vacuum to the carb. Also the single hole spacer combines with the volume of the manifold plenum to give an effectively larger plenum. Plenums are a good way to divide airflows evenly so the engine is probably filling the cylinders more uniformly. I have thought about tapering the primary holes of a 4 hole towards the rear giving a smoother transistion to the rear of the engine. This should allow the air go to the back of the engine easier at part throttle. I have never seen such a modification described or tested but maybe someone else has tried it. Remember that as difficult as it is for air to turn corners the droplets of fuel have a far harder time. So this modification of a 4 hole might give more uniform distribution of fuel from front to rear thus giving better milage than is otherwise obtained. The effect might not be very large so it probably would take an engine dyno test to demonstrate if the idea works. Also as Frank notes these effects are very combination specific, what helps in one case may hurt in another.

|

|

By NewPunkRKR - 16 Years Ago

|

|

I used a bridgeport vertical mill to open on the holes on the intake. I matched them to the spacer I was using, which ended up being a pretty big bore. I realised after the fact that they are much larger than the carb bores, but I should have no restrictions then. the only thing I didn't do was get rid of the bump down inside the top right leg. No easy way to do it. I epoxied the surface and filed flat. Now I just need to wait for the paint to dry. My new Demon Jr. is waiting for action. - John

|

|

By pcmenten - 16 Years Ago

|

Very, very nicely done. That looks like the right way to do the modification. You left a lot of the diameter of the hole in place and I think that will help the airflow around the throttle plates at part throttle.

I will be interested to hear about your impressions of the engine's performance when it's back on the road.

|

|

By NewPunkRKR - 16 Years Ago

|

|

Installed new configuration today: Demon Jr. w/ 1" BG phelonic spacer on modified B intake. Initial Thoughts w/ no carb tuning: starts great, crisp throttle responce. I don't know if I'm just expecting gains, but the car feels like it has more power across the board. I can definately tell the difference if I hit the gas at about 40... Firm downshift and it pulls nicely. It does bog down a bit if I'm at about 35 mph and I give it a little throttle, but I think some tuning will clean it up. But I'm very happy over all! Worth the time / money / effort. - John

|

|

By Duck - 16 Years Ago

|

Doug T (2/5/2009)

This is what you need to do. Slot the holes together.Thenlook into the right side hole no matter which end you look from and you will see an obvious restriction where the passage on the right side dives under the cross runner. Grind on this to open it out. The left side is not so restricted and doesn't need much. Radius the holes where they start at the flange so that the flow does not have to go over the sharp edges left over when the holes were machined. This pic shows a manifold thathas the grinding finishedbut ithas not cleaned up by blasting. After blasting fill the surface of the flange including the space between the slots with an epoxy glue mixed with the iron filings that you have saved from the grinding.Grinding is not the right word because I don't useabrasive stones forany of this, I do it all with carbide tools and a high speed, electric die grinder. Level the hardened glue/iron mix with a file. I also plug the hot air tube with a 5/16 bolt on both sides and I don't run the heat in the exhaust plenum, However this means things are slooooow to warm up! I like a 4 hole spacer for slightly crisper throttle responce. I used a manifold modified like this before the BlueThunder was available and had my engine dyno tested. This manifold modification supported over 325 hp on pump gas normally asperated,so it does work. " Radius the holes where they start at the flange so that the flow does not have to go over the sharp edges left over when the holes were machined." Doug- Just a confirmation, please- Are you saying to chamfer the inside, top edges of the slots? I've so far slotted the holes on a friends Bridgeport, J/B Weld mixed w/ filings to close up the voids has been applyed and has now hardened. I'll be filing to shape and am just wondering if I understood you correctly? -Thanks- /Duck

|

|

By Duck - 16 Years Ago

|

*BUMP* before it falls off the page, already...

|

|

By GREENBIRD56 - 16 Years Ago

|

|

Duck - I think what he's referring to are the sharp edges on the bottom of the carb deck. Where the machining has broken through the "ceiling" of the plenum. If you maintain the four holes -and don't cut slots - to try and keep the crossection fairly constant below the primary... say bore them oversize to match the spacer and carb if you will - then this would be "flaring" the exit on the bottom side. When slots are used, the trailing edge of the carb bore would be abrupt with an open spacer - could be eased with a four hole spacer flared to the rear on the bottom. But forward - the flare would be on the underside of the plenum ceiling.....I can draw this better than explain it - but need more coffee..... Did your finished job look like which picture? (two full slots or two holes joined) and what spacer do you intend to use?

|

|

By Duck - 16 Years Ago

|

|

Thanks, Steve; I've slotted the intake front to back,and left the middle divider. I plan on using the T-bird 4 hole spacer w/ the PCV provision. Maybe I read Doug's explanation wrong (?) I did notice when I put the spacer on the intake after I milled it (intake) that the rear-most portions of the slots (cast iron) show when looking down the spacer's rear holes. I presume these "ledges" will need to be filed away. I equated that to the "chamfering" of the upper, inside of the slots (?) hope this makes sense... -Thanks- /Duck

|

|

By GREENBIRD56 - 16 Years Ago

|

|

There need to be no steps under the carb venturi - if you open the throttle wide open do you see a step at the spacer? and then a step at the manifold lip? My outfit has the OEM holes -so I made the tapered spacer I sent the diagram of. If you are using the OEM spacer - does it have holes larger than the carb base?

|

|

By Duck - 16 Years Ago

|

"Kill the steps"- Got it. Thanks, Steve. I appreciate your help  /Duck /Duck

|

|

By GREENBIRD56 - 16 Years Ago

|

|

Duck - When these guys milled (or ground out) the slots between the manifold throttle bore openings - they also opened up the bores to match the opening on the bottom of the carb. The diameter of the holes in the "B" manifold is 1-7/16 - and the holes in the bottom of my Demon 525 are about 1-11/16. There isn't much of the rim around the hole in the manifold left if you get things opened up that far. Is there some meat in the spacer to allow creating a bit of a transition taper? I used a phenolic spacer and tapered/blended beneath the throttle plate to get that smooth transition to the manifold hole.

|

|

By Duck - 16 Years Ago

|

|

Steve- With just the aluminum spacer in place on the intake, there's a noticeable "step" where it mates to the intake. No way to do any type of transition, the way I see it (?) it's as if the spacer's holes are the larger of the two. I believe the best I can do will be eliminate all the "steps" and hog out the 2 steps in the bottom (inside) of the intake.

|

|

By GREENBIRD56 - 16 Years Ago

|

|

What sort of carb are you going to use? Both the 600 cfm Holley that used to be on mine - and the Road Demon - have their own PCV vacuum ports. And I've got that hooked up to a PCV valve at the original T-bird valley hole (the one for the road draft tube). You got a new valley cover - right? How are you going to work the PCV? That set-up Dutchy showed us is the way to go I think - the pipe tapped hole into the galley. This picture is an old one - but - I really "funneled" the spacer openings under the carb to make all of the edges match up as smooth as possible. Between the 1/2 inch of phenolic material - and the air gap under it (this is an unmodified intake) - the carb stays pretty cool.

|

|

By Duck - 16 Years Ago

|

AZ28 (9/7/2009)

What sort of carb are you going to use? Both the 600 cfm Holley that used to be on mine - and the Road Demon - have their own PCV vacuum ports. And I've got that hooked up to a PCV valve at the original T-bird valley hole (the one for theroad draft tube).You got a new valley cover - right? How are you going to work the PCV? That set-up Dutchy showed us is the way to go I think - the pipe tapped hole into the galley. This picture is an old one - but - I really "funneled" the spacer openings under the carb to make all of the edges match up as smooth as possible. Between the 1/2 inch of phenolic material - and the air gap under it(this is an unmodified intake) - the carb stays pretty cool.  Steve- I had the Holley rebuild facility assemble a carb to the original appearance/ spec of the '57 T-bird. No PCV provision. The valley cover had a boss for a PCV grommet hole which I drilled for the proper size grommet. The hole is offset to the driver side though, so I'll have to bend up a short piece of steel line to make it all work.Other than that, "Bob's my uncle".... /Duck

|

|

By LM14 - 16 Years Ago

|

|

The only way you will actually know about what spacer to use is with dyno time. We spent a bit of time on it during one dyno session (approx 550HP Brodix headed/Motorpsorts block dirt late model engine) and found that the HP and torque didn't change between a 1" open and a 1" 4 hole and a 2" open and a 2" 4 hole but the place those max figures happened moved. On another engine, we always ran a 2" spacer and saw about 7 to 10 HP. Didn't matter if it had 1 or 4 holes. Driver preferred 4 hole and could tell the difference by the way the car came off the corner under full throttle. I would encurage you to play with it and see what feels the best. We had one motor that actually preferred the Motorcraft 3/8" tall heat insulating spacer and that motor gained almost 20HP every time we went back to it after trying something else. Just a few thoughts, SPark

|

|

By Duck - 16 Years Ago

|

|

That all makes sense to me- the only problem is T-birds are prone to clearance issues with anything more than a 1/2'' spacer. The one I'll run is a 4 hole... /Duck

|