|

By NewPunkRKR - 18 Years Ago

|

|

The trans in my '57 fairlane is starting to slip after about 5 mins of driving. If I put it in 1st and start out slow it's ok, but if I just hammer on it in drive it squeals. The plate says "Ford Automatic Transmission, 103D-150896, Marvel Schebler Prod. Div., Borg-Warner" Haven't been able to locate any information on it, is it an original ford-o-matic?? I talked with a local shop, and the guy was very familiar with the 50's fords and said he could rebuild them in his sleep (unfortunately i didn't have the number information when i spoke to him) Is it worth it for me to rebuild it? He said it would be about $800 to pull it apart and go through the whole thing. I got the car 2 summers ago, and while it didn't run when i got it, its slowly turning into a great running car. I've got a 312 w/ holley 570 street avenger on 1" spacer, MSD dist/blaster coil/ignition control/timing control, headers to 40 series flowmasters w/ rear axel dumps. I'm looking to do intake and cam next - I want to build a fast car, but i don't want to rebuild the trans only to trash it again. Any thoughts or recommendations??? I'm doing some body and paint work and then maybe i'll get a picture up. I've got tons of questions and a lot to learn, but that's enough for this post. Thanks in advance for your help! - John

|

|

By Glen Henderson - 18 Years Ago

|

|

Yes, its worth a rebuild, but you have several other options. Upgrade to FMX, C4, or AOD. The price $800 seems a little high to me, I got $75 in the 60's to rebuild one, but in todays $'s it may be a fair price. The upgrades will all cost you more than $800 unless you do your own work. The FMX could be done for about the same price if you can find the flexplate and a rebuildable core. This topic has been discussed and debated in great length and looking through old post should give you an idea of other members ideas. For my money the FMX is the least expensive and best option.

|

|

By NewPunkRKR - 18 Years Ago

|

|

Yeah, yesterday I spent most of the night reading through all the old posts after I put up my note. I also wasn't sure what the concensus was on what people were running and felt was the battleship of the drivelines. Thanks for your help!

|

|

By NewPunkRKR - 18 Years Ago

|

|

After lots of reading and $$ considerations, I'm going to stick with the FOM for now. Anyone know where I can find upgrade parts (if they exist) for the FOM. Also, is there anything you guys would recommend that I check or change while I have the trans off? I saw John Mummert has the aluminum flywheel, any advice is greatly appreciated. THANKS! - John

|

|

By MoonShadow - 18 Years Ago

|

|

Ask Jay about using a later Cruise O Matic valve body to get a true 3 speed shift. Chuck

|

|

By marvsmerc - 18 Years Ago

|

|

I am in the same boat as I am contemplating on rebuilding the mercomatic, which I am going to take out as soon as it warms up around here,or switch to a later Tranny.. I am researching the adapter kits for the newer ford transmissions,FMX,C-4 or AOD to the Y-block. I was wondering about the cooling part of this switch since the fordomatics,mercomatics are air cooled. Also, does the driveshaft have to be modified?. Can anyone fill me in on this? Thanks, Mike

|

|

By Glen Henderson - 18 Years Ago

|

|

You will need a good aftermarket cooler , unless you replace the rad with one with a built in cooler. The drive shaft will have to be replaced or reworked depending on the trans that you use. One option would be to use the front pump, torque converter,tailshaft, tailshaft housing from the FOM in a FMX case. This would give you a trans with the same dimensions as the FOM and allow you to use your stock driveshaft.

|

|

By NewPunkRKR - 18 Years Ago

|

|

I was planning on adding an aftermarket cooler. Should I just bypass the rad. cooler all together, or put it in seriers with a new one? I can't imagine having both would do any harm. - John

|

|

By Canadian Hot Rodder - 18 Years Ago

|

|

I am just running a aftermarket trans cooler behind my front bumper on my 56. Keeps the FMX plenty cool. Rob

|

|

By MoonShadow - 18 Years Ago

|

|

Basicly the more cooling area the better. But you also have to factor the hose length and the number of connections. The more stuff the more likely a failure. I think I'd just get a good tranz cooler and go with that. Chuck

|

|

By NewPunkRKR - 18 Years Ago

|

|

Thanks for the tips. Spoke with Jay at broader performance and I think we've got a good solution. I managed to get the trans out (smashed my thumb in the process... it got ugly... so is my thumb) - but still have to pull the bellhousing and torque converter but I ran out of daylight. Any tips from here? Thanks everyone for your continued help. A couple weeks ago, I wouldn't have thought that I would have taken this project on myself, but so far so good. - John

|

|

By Y block Billy - 18 Years Ago

|

|

I read once where too cold a transmission is not good, they are rated to run at a certain temperature, I don't know what that is on the top of my head but I think around the same temp as the radiator 170 -190, if you have ever noticed starting in the cold winter it takes a few moments before the trans kicks in once the fluid warms up. When it is too cold I believe the radiator actually is used to warm the trans fluid at certain times to maintain the steady trans temp.

|

|

By NewPunkRKR - 18 Years Ago

|

|

HELP... Got the trans back and after getting it mounted to the motor I find out a major problem... It was suppose to have th FOM tail housing and it doesn't. So, I'm sure you all know where i'm going with this one - It doesn't mount to the cross member and the drive shaft is about 2-3" too short. I remember seeing pictures of someone who had added a support section to the cross member, but I couldn't find it in a search. Also, any thoughts on the drive shaft??? I've hit my $ limit on this project and can't put up a load of money to have it extended. I put a call into Jay at broader performance to find out what happened, but I obviously won't hear back until tomorrow, so any wisdom in the mean time would be appreciated. As I type this I'm laying under the car in the driveway reviewing my options. Also, Glen - I received the dip stick tube (10 mins with the wire wheel and a little spray paint cleaned it up good as new) THANKS! I think if not for the tube itself I need to send you some $ compensation for the time it took to put all those stamps on the packaging, yikes  - John

|

|

By Glen Henderson - 18 Years Ago

|

|

Glad it worked out for you, as for as the stamps, I just paid the postmaster, he licked all the stamps. I am sure he is trying to get ride of all the 34's and 37's that ain't good anymore. If you are close to a junkyard measure up a later big ford drive shaft, you might get lucky. I have one from a 63 merc, that I will check the length on. You may be able to extend the crossmember mount with a piece of channel or fab it from flat bar.

|

|

By NewPunkRKR - 18 Years Ago

|

Ok, so no worries. I paniced prematurely (idiot) - there is an additional bracket for the tailhousing that is in one of the boxes of parts that I got back from Jay...  I think the driveshaft seemed like it wasn't in all the way because of the angle that the trans was sitting and the alignment to the rear axel, and in my mind I was already thinking problem. I think the driveshaft seemed like it wasn't in all the way because of the angle that the trans was sitting and the alignment to the rear axel, and in my mind I was already thinking problem. The good news is that I should get it finished up tonight. I'll start her up with open headers and get a video posted before I put the exhaust back on.  Should be pretty wicked. Should be pretty wicked. - John

|

|

By Glen Henderson - 18 Years Ago

|

|

Glad you got it figured out, but just in case anyone ever runs into a drive shaft shortage (no pun intended) I just measured the 63 merc drive shaft 57 1/2" center to center of joint, 57 fairlane 56 5/8" center to center. The front yoke on the merc is about 3" longer than the 57, but could be cut down or replaced with a 57 unit. The only custom drive shaft that I have is still in the old parts car and I didn't fill like fighting the snakes and spiders to measure it, but I am sure it is several in's shorter than the fairlane requiring that the later unit be cut down. Just for info if anyone can use it.

|

|

By NewPunkRKR - 18 Years Ago

|

|

Last night was not entirely successful: Is it possible to buy trans cooler line stock (similar to brake lines)? I can't seem to find anything online. My old ones were damaged from when I took the trans out and I'm trying to add an aftermarket cooler infront of the radiator. I see running rubber hose the whole way as trouble, nor do I see a good place for them to go. (correct me if I'm wrong because rubber would be easier) I want to try to atleast get from the trans to the radiator with steel (which I figure I can run along the bottom of the block where they were originally, and then I can run around the radiator to the cooler in rubber. Also, I've got about 1-1.5" of shaft showing between the tail housing and the yoke/U joints. Is this normal, I don't remember what it looked like before I took everything apart. I should have taken more picures.  Edit: I just found this: http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_317274_-1 I'd have to imagine it's the same type of tubing and I could get the same stuff/fittings at Napa or Autozone... Sorry for my ignorance, I have no experience in doing this type of stuff and decided to just dive in on this project.  - John

|

|

By MoonShadow - 18 Years Ago

|

|

Basicly any line of the correct size will work. Your local parts store should have it. If you can make them to connect directly at both ends that would be best. If not use a rubber line that is rated for ATF use. Make sure the clamps are on straight and tight. Regular fuel hose will break down with transmission fluid. Most of my vehicle automatics have had steel lines with 3"-4" of rubber at each end and work fine. Chuck in NH

|

|

By NewPunkRKR - 18 Years Ago

|

Damn, that's it - I looked back at some pictures of the trans when I pulled it and it had a bulge on the end. Another thing I need to order - eh  Thanks! Thanks! - John

|

|

By Glen Henderson - 18 Years Ago

|

|

You should be able to get 3/8 steel lines in different lengths from your parts store and fab up a set of cooler lines. A trick that I use is too take gas welding rods and bend it up until I get a pattern that I like, then use a tubing bender to bend your new tubing to match it. You don't have to make the full run out of one piece of tubing, bend up a front section and a rear section and use a union to connect the two. Takes a little time, but not too tough a job.

|

|

By NewPunkRKR - 18 Years Ago

|

|

Ok, the good news is I managed to pipe from the trans all the way to the cooler using the stock holder with 5/16" pipe/fittings and then used about 12" of rubber to connect to the cooler. I'm real happy with how it came out and it looks pretty slick, and no leaks so far. I started the car up straight headers... it was LOUD!!! too loud... I got a video, but I have to put the exhaust back on, I can't drive like that. The bad news is that I've got a leak at the bottom of the trans where the case meets the tail housing. I tried to tighten those bolts on the back but they are solid. After about 5 mins of running the motor at about an idle and shifting through the gears there was a decent spot on the driveway. Any thoughts - Really don't want to have to drop the trans again. Also, the kickdown rod seems about .5-1" too short. With it set the same length as when I took out the FOM, it doesn't quite reach the hole. If I adjust it longer, it doesn't seem like there is enought thread holding it. I mounted it as is, but then the throttle linkage was too short and when I adjusted that, I'd have to press the gas down about 50% before anything happened. So, my only guess is that I have to lengthen it. (possibly by straightening it some?) Or adjust the attachment location on the throttle linkage. I'm getting close. Any help always apprecaited. - john

|

|

By NewPunkRKR - 18 Years Ago

|

|

All I was told - "Its possible there is some difference in the gasket. The trans uses the FMX pump so the leak is most likely between the ext housing and pump. I would just pull the ext housing and put some sealer on it." So nothing more than I've already been told and I'm on my own to fix it. What can I expect when I pull that off? Is there a lot that I'm going to have to disassemble or something that could fall out of place... I'd like to try and loosen it up a hair, slide in some gasket material and some RTV and tighen it back up. John you said if I feel lucky... is that too risky a move? I assume either way I've gotta drain all the fluid, and I can't reuse it correct? Thanks as always for all your help! - John

|

|

By NewPunkRKR - 18 Years Ago

|

Thanks John - pulled it back a smidge, put a bead of RTV, and seems to have sealed it right up. I shifted through the column with the car on blocks and forward/reverse was all good. So I took it for the first test drive and all seemed well except... it wouldn't shift. I made sure I wasn't in 2nd or anything like that. The kickdown lever is not hooked up because of the forementioned problem with the length, but I didn't think that would make a different. I have a feeling there was a problem with how I hooked up the vacuum modulator... would that result in the lack of shifting. I'm slowly making progress, but got rained out this evening.

Edit: I've answered my own question: I did some research online and now fully understand the purpose of the vacuum modulator. So basic yet so valuable... I gaurentee its my vacuum line. Thanks!

- John

|

|

By NewPunkRKR - 18 Years Ago

|

I'm sure everyone is getting tired this topic on my trans, but believe me that I am too.  When I first put in the trans the kickdown rod was too short to connect from the trans lever to the control lever on the throttle linkage. (even though I never changed anything when I pulled the FOM) So I tried to lengthen the rod, but then my carb linkage wasn't right and it wouldn't returnn to idle. So adjusted that, but then the carb blades weren't opening fully with the gas pressed all the way. So I played with the springs on the linkage, and found some middle ground so everything SEEMED to fit together. So I go for a test drive and the trans seemed ok doing under 30 and feathering the gas. Then i pulled out on a main road and I hammered it. The thing reved up to about 50 in first gear and wouldn't shift until I let off the gas entirely, and then as soon as I would add the smallest amoung of throttle at 30-40 mph the car would immediately down shift until I let off, and shift back up - this would repeat so the car was really jerky and shifting down/up, down/up, down/up. Basically, the kickdown is "kicking in" all the time. So I took off all the springs and connections to see how it "should be" but, there doesn't seem to be enough travel in kickdown lever on the trans to match the amount of travel required by the throttle linkage for it to work properly. Does this make any sense? I've read the shop manual, looked over other threads and I can't get this to work right. Could there be something with my trans that this just isn't going to work properly with the FOM linkage, or is this a normal thing that I'm just stuck with, at this point I'm about to just forget the kick down. All help always apprecaited.. - John

|

|

By NewPunkRKR - 18 Years Ago

|

|

I believe I've got everything adjusted correctly, but the kickdown still isn't right. It down shifts at around 50% throttle. It is clear that there either isn't enough travel in the lever on the trans, to match that of the throttle linkage, or there is some setting in the trans so that it is down shifting before the lever is pushed all the way down. It's not horrible, but it is kind of obnoxious, and I think it will hurt gas mileage quite a bit. Oh well  - John

|

|

By GREENBIRD56 - 18 Years Ago

|

|

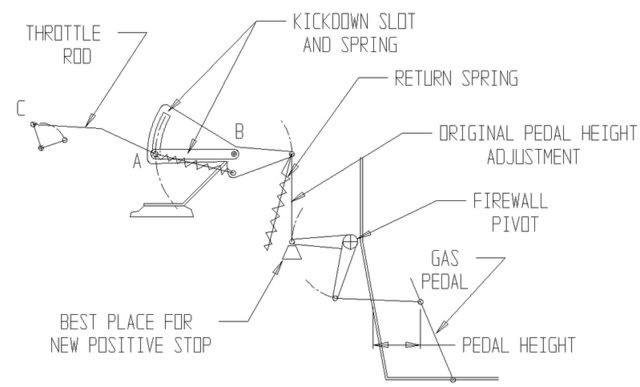

Aw...come'on -you didn't put that scoop on there to help the mileage did ya? Can you make an extension for the transmission lever so as to alter the rate of change as the throttle advances? (Or vice versa - a different hole on the carb lever) I don't have a p[icture that shows me how yours works exactly - but the '56 throttle opens the carb up all of the way - and when it hits the carb stops - there is a spring loaded "overtravel slot" that lets the trans linkage continue on. This means the angular rotation of the throttle is "quicker" than the angular rotation of the kickdown for any amount of pedal.

|

|

By 2DRHRDTP57 - 18 Years Ago

|

Hey John, You and I have experienced a lot of similar problems. I read every page of my 57 Ford manual only not to find anything regarding this kickdown linkage adjustment. In the end I struck gold by purchasing a 1956 1957 Fordamatic Shop Manual from e bay. The adjustment method that I have attached will sure fix your problem if you follow it to a t. You may have to adjust your carb link and pedal to bellcrank link as well, to get everything sweet. the throttle control rod they refer to is your kickdown rod. Only Fig 6 and Fig 8 apply to your 8 cylinder passenger car vehicle. Be sure not to use the 6 cylinder method or truck. I hope you can save to file and resize so you can read this as it has compressed on the forum site, If not you may be able to get a copy locally, or if you PM me your email address I will forward direct, Hope this helps John

|

|

By GREENBIRD56 - 18 Years Ago

|

|

The "missing link" that I've had to find in the old Fordo manual before - is the recommended distance between the pedal and floorboard at neutral. There has to be enough bellcrank rotation (out on the firewall) to (1) fully open the carb throttle and then (2) continue to move the trans "kick-down" rod with rotation within the "overtravel" slot. This additional travel is commanding the transmission control pressure to rise. If you don't have enough space to "floor it" and get the full range of motion (command full pressure as well as full throttle) - the kickdown is defeated. You can get wide open throttle but not enough movement in the trans control to get the matching internal pressure. What I found was that technicians (that don't know about the floorboard space requirement) often adjust the kickdown rod to get a raised control pressure at a reduced carb throttle position. This is a simple approach but it may make the tranny kickdown too early, at part throttle. The Fordo manual recommends using a pressure gauge off a specific test port to detect control pressure under various operating conditions - it would catch the problem but.....you have to be deeper into this than most want to go. Also creeping in here - on my outfit and maybe this one - the Holley 600 cfm 4160 throttle had a selection of several different lever ratios (holes) - the teapot carb that came off had one. The distance from the throttle blade shaft center to the attachment point of the linkage arm is important to the total picture. John's comments about the mismatched springs could be tricky to catch - and would explain some variations of bad behavior. Often, the replacement springs sold by the aftermarket are not an exact match for the Ford parts - and if you have a competition rules regulation for instance, that governs throttle return springs - this mismatch could get a lot harder to deal with.

|

|

By MoonShadow - 18 Years Ago

|

|

How do you adjust the height of the pedal from the floor? My setup doesn't have an adjuster from the firewall to the bellcrank. Chuck

|

|

By GREENBIRD56 - 18 Years Ago

|

|

Good morning Chuck! - On my '56 Bird, its the two joined 90° ball joints that jump the foot feed motion from the firewall bellcrank to the linkage on the engine itself. As usual it is completely covered in this photo - Sorry. According to the "directions" for the '56 - you set-up your idle, with the tension spring holding the overtravel slot closed (with a 1/4 rod - Phillips screwdriver - in the linkage lock holes) - then adjust this length to lift the pedal up off the floor a specific amount.

On mine you have to take the link loose, release the locknut, spin it a few threads and then try it. I never found the "required dimension" of the pedal off the floor 'till I bought the blue Fordo manual. I have a spring tension problem in mine - which John pointed out this morning - so more work is going to be required to make it behave just right. When all is well with the throttle - then you start on syncronizing the tranny control pressure to the linkage position. The control pressure will be low at idle, steadily increasing to full throttle - then after you enter the "overtravel" slot - pressure must reach the point of operating the "kickdown". I think you should be able to "just" reach full throttle and not cause a kickdown - but I will need to get a pressure gauge set-up to do it. Part of the problem (as I see it) is the way the Fordo transmission is rigged to start in 2nd gear. The tranny control pressure is initially "soft" to facilitate a smooth acceleration from stop - unless you completely floor it into the overtravel slot. Builds heat like crazy in normal driving.

|

|

By GREENBIRD56 - 18 Years Ago

|

|

John - The return spring shown in the photo is indeed the original I found on the car when I bought it. It has had a few turns in the caustic to get the gunk and old paint off - then a little acid, gun blue and WD40 to finish. Its in good shape and hasn't been deformed. I have a replacement spring I got from NPD and it was too stiff - way more tension (coils painted together too) than this one. The linkage assembly on the intake hasn't been altered - just mounted flat on the '57 manifold base pads. Need to check the elevation of this point versus the old 9425-A manifold don't I...could add preload to the spring.... The trouble is, even assembled with this original spring - it is not stable at the point shown in the photo. And if you abruptly remove your foot from the foot pedal (as in - slip your foot off sideways) or simply pull out the screwdriver - the linkage doesn't want to return to the neutral point where it is locked in the photo. Instead, it over-travels in the close direction and moves the rear carb link attachment point too far upward. It then "toggles over" and latches against the carb lever (which is tight against its own stop screw). This is bad news...... The upper attachment of the return spring is plainly built to be adjusted by (gentle) bending (I think). How tight should the spring tension be? Does the tab need bent down to relax the situation a bit? Should it just have enough tension to hold things at neutral? I've got a lot more questions than answers. It doesn't seem too stable to me to be balancing everything on springs. I'm pretty sure that using this linkage - intended for the teapot - with this style of carb and spacer has resulted in some differences in the elevation and arc travel of the linkage points. This then contributes to the "toggle" situation. I've got the forward pivot of the carb link rod in the best match of holes in the throttle lever of the 4160 - to try to match the travel of the teapot lever. This may not be the optimum spot to hang it - the bigger carb and other tuning changes is liable to make the road speed considerably different for a given throttle position. The best arrangement I can come up with, is to build a hidden mechanical stop screw and locknut that causes the linkage to absolutely stop at the proper neutral point. I was also thinking it might be a good idea to figure out a way to change the arc of motion to the tranny pressure control rod (kick down). If the throttle position for a given road speed is reduced by the bigger carb - won't the transmission control end up in the wrong pressure range for "cruise"?

|

|

By GREENBIRD56 - 18 Years Ago

|

|

This is where my problem lies - points C-A-B fall too close to a straight line - and the return spring is forcing A to go up above C.

I'm thinking that I can get a little mechanical stop to fit on the back of the block. It will then be the adjustment that sets the pedal height and the return spring can be fairly stiff. Extending the throttle rod and the original pedal adjustment link will move A down out of line. But yes, I see - it may be that the pressure control rod set-up will be too close to kickdown for comfort.

|

|

By GREENBIRD56 - 18 Years Ago

|

|

Brody - Thanks for the tip about the washers - it raises up the "B" shaft pivot in short order. I've got some 1/8 strap around to make a common spacer - thick enough? I have to admit I was considering getting a big crescent wrench on the bracket and bending it up a bit. Old habits die hard....... Did you adjust the spring hanger down (after you moved the bracket up) to lighten the return pressure a bit? Surely there's something I can bend on there.....

|

|

By NewPunkRKR - 18 Years Ago

|

|

I'm glad this thread opened up some heavy discussion on setting these linkages properly. To eliminate any confusion, I am not running a stock FOM. I have a modified FMX trans. I'm using the FOM bellhousing/tailhousing/outer lever arms, and then a number of FOM internal components inside an FMX case. This was custom built by Broader Performance. I adjusted all the linkages using the screw driver through the holes to line everything up properly. I know my springs are not original, but after much testing I don't believe they are affecting the way the kickdown should operate. In my attached picture I added points D (wide open throttle), E (point at which carb reaches full throttle), F (bottoming of kickdown). When pressing the accelerator all the way down, the carb opens all the way, and once it stops, the kickdown plate continues to rotate down just a shade farther before bottoming on the kickdown rod. If I understand correctly this is how it is supposed to work. After a lot of driving taking careful notes of the conditions at which the trans down shifts, I've noticed a trend. It downshifts when the vacuum hits 0 (no matter what speed, as long as I'm below 60 mph), regardless if the kickdown lever is bottomed (at point E or F) or not. If I take off the kickdown linkage and drive, it doesn't down shift at all. So I would have to believe that it would be an internal issue in the way the trans was built. It is looking for the lever to be pressed and the low vacuum but it isn't requiring the kickdown be pressed fully... Does this make sense? I think the only thing I could do would be to have to build some sort of secondary kick down similar to the positive stop that would not move at all until the pedal is fully pressed. Any thoughts always appreciated. - John Edit: Second thought - I do have a 1" carb spacer... could this be affecting the amount of travel it takes to hit full throttle. Maybe my point E should be 1/2 the distance that it is??? 2nd Edit: Would my secondaries opening too soon be creating the problem of the vacuum crashing to 0? If i remember correctly from a post by Ted, with the vaccuum secondaries they only open as much as they need???

|

|

By NewPunkRKR - 18 Years Ago

|

|

I have both, because that's how the trans arrived at my door... (bad reason I know, I don't like accepting things "just because") - I believe because of the configuration the vacuum modulator is necessary (the trans doesn't shift without it), but when I drove without the kickdown, it seemed that the trans wouldn't down shift... All advice or suggestions appreciated. - John

|

|

By NewPunkRKR - 18 Years Ago

|

|

Thanks, you all have been extremely helpful on this, especially you John... (I've probably made it a little harder on myself since I'm researching FOM shift linkage adjusting, but trying to apply it directly to the FMX.) Based on what I've learned is it correct to assume the following: 1) The modulator controls the up shift and reads the engine vacuum to determine load (0-20 on vacuum), and so if it reads 0 it will hold out the gear until a determined rotational speed (I think 40 mph in 1st, 60 mph in 2nd???) Hence the reason the car wouldn't shift, when I didn't have the vacuum hooked up; it thinks I've got the carb fully open. 2) Because of the existance of the modular in this application the kickdown is NOT a positive yes or no on the down shift... The position of the kickdown in its path length determines how hard of a down shift is required? The down shift will always occur at 0 vacuum, but the kickdown all the way up would mean no down shift (what happened when I took the rod out) , and all the way down would be as hard as possible. 3) Then depending on the rotational speed of the trans, it determines what gear it should be in using the 2 items and variables discussed above, and then at 60 mph in 3rd gear, it is beyond the range of 2nd gear and therefore will not downshift. So with all that in mind, my trans / linkage would be all functioning correctly if using the FOM - which is why I had no problems before the trans swap. The issue is that because the vacuum drops out to 0 before full throttle, the modulator thinks I'm at full throttle and engages the shift. (Thanks if you've made it this far through the post :hehe If all the above is correct, is there a reason/problem that I'm dropping vacuum pressure to 0 before full throttle? Would it be that my secondaries are opening too quickly? In regards to adjusting the modulator, you're saying that would only change the timing of shifts occuring under normal driving (shifts occuring above 0 vacuum)? So it wouldn't have any effect on the type of shifts I'm discussing. If I'm wrong above I'm going to be really lost  , so hopefully it all makes sense. Thank you as always, all comments appreciated. - John , so hopefully it all makes sense. Thank you as always, all comments appreciated. - John P.S. The tach/vacuum/oil pressure/fuel ratio gauges have been instrumental in all of my problem solving - I would highly recommend any of the above to anyone.

|

|

By GREENBIRD56 - 18 Years Ago

|

|

You don't have a big ol' vacuum leak somewhere do you? It could be assisting in lowering the total manifold vacuum.

|

|

By NewPunkRKR - 18 Years Ago

|

|

Vacuum is 19-20 at idle, 15-18 in gear, or crusin down the road. This is the reply from Broader Perf: "The FMX kickdown does have much less travel than the FOM. Think of the kickdown as an on/off switch. It should only depress and WOT. You bell crank may not work for this. You will have to modify it Im sure. If it does not want to work for you you may need to try a Lokar kickdown kit or something similar. The FOM used the bell crank to sense throttle position. The FMX uses the vacuum line to sense throttle position. I would recommend disconnecting the kickdown until you can rig something up." I assume it supposed to read, it should only "depress at wide open throttle" - Wouldn't 0 vacuum mean that the carb is at wide open throttle? Could it be that the secondaries are opening early before the primary barrels are open all the way therefore making the engine think it is at full throttle - would this make sense since I have a 570 cfm carb which is clearly more than my 312 is pulling in? If I'm wrong I might just have to create some custom linkage... - John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: Does the trans rear seal have a dust boot on it? The original probably did, which would hide about an inch of the yoke that you see. If the new seal has the boot and you still see that much shaft, it would seem that the driveshaft is a little short. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: That boot isn't really necessary. They were usually part of the rear seal, some seal manufacturers left them off. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: I know exactly why your trans leaks. The FMX tail housing gasket was used with the FOM housing. One of the lower corners of the FOM housing is a rounded square corner, the FMX corner has a 45 degree cut corner. The FOM gasket will seal, the FMX will not. You can change it without pulling the trans, you can pull the tailhousing off. Or, if you feel lucky, loosen the tail housing, move it back about 1/2", stick a piece of gasket material in the suspect area, and bolt it back up. A dab of RTV wouldn't hurt. You should be able to do the above without even taking the driveshaft out. Be sure the 1/4" plate between the case and the tail housing stays against the case so the rear thrust bearing won't drop out of place. Or contact your trans rebuilder and see what he wants to do about it. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: My thought is, it's worth a try to slide it back a little and slip a piece of soft gasket material in with some RTV. You wouldn't have to unhook anything. Just don't let the 1/4" pump plate back away from the case, nothing will drop out. The fluid level will probably be below this point, but a little fluid will be inside the tail housing. Put a pan under and let it drip while you work. If, worst case, this doesn't work, you are not out anything. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: Sounds like your kickdown rod is too long. You can start with it adjusted so that when the carb blades are at full open and the kickdown lever all the way down at the same time. That should eliminate it downshifting without full throttle. You could also unhook the kickdown rod to see if the trans behaves, though the shifts may be a little soft without the rod. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: I helped a friend sort his throttle/transmission problems on his '56. He had such a strong return spring on the carburetor that when he pushed the pedal, the bellcrank on the back of the manifold went into "kickdown" position as AZ28 mentioned, which caused early kickdown and lack of full throttle at the carburetor. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

Steve: I don't believe you have the return spring problem. Yours appears correct. The throttle return spring is the vertical one in your picture. It returns the bellcrank, which in turn pushes the carb closed. The '56 I referred to earlier also had a return spring on the throttle lever to pull the carb closed, and that was the one that caused the bellcrank to go into "kickdown" position as soon as you pushed on the accelerator. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

Steve: Is the pivot of the bellcrank worn to the point to allow the carb lever to toggle over? If not, the positive stop looks like the safest solution. Lengthening the carb rod would stop the toggling over, but full throttle would probably not happen. I don't think the change in throttle pressure would be enough to matter at cruise, as long as it doesn't downshift too easily. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: Try to think of it this way. The kickdown rod is also a throttle pressure rod. What it does is tell the transmission how hard you are pushing the throttle, so that it knows how hard to make the shift. Light throttle, low pressure, soft smooth shift. Heavy throttle, high pressure, firm no-slip shift. The vacuum modulater tells the trans when to shift, based on engine load (vacuum). Typically, you adjust the kickdown rod by road testing after you make the initial adjustments. I ususally shorten it about 3 turns, verify no kick down, then lengthen it a turn at a time until I get kick down. Also, many FMX modulators are adjustable. Pull off the hose and use a pocket screwdriver to turn the screw inside the hose nipple. Clockwise adjustment puts more tension on the modulator spring, making the shifts occur later. Counterclockwise reduces spring pressure, making earlier shifts. These are part throttle shifts, not full throttle. John

|

|

By Hoosier Hurricane - 18 Years Ago

|

|

John: Re-read Broader's answer. The FMX kickdown is a mechanical off/on switch. Nothing to do with vacuum. Vacuum is the modulator's signal. You can always delete the kickdown rod, and when you want to downshift, manually move the shift lever to 2 or 1. John

|