|

By oldcarmark - 15 Years Ago

|

|

I finally got to take my rebuild out for a drive today.Runs great.Starts quick and has lots of power.Timing is set at 12BTC.Idles great in neutral.I cant get it to idle in drive.Will almost stall.Vacuum is good at 18 and I dont think there is a vacuum leak.Holley 390 which I used last summer and worked fine.I have blown out the idle passsgaes and bleed ports.If this is a needle and seat problem why would it run fine except in drive idling?Its a stock type camshaft.Any sugestions on what to check?

|

|

By YellowWing - 15 Years Ago

|

|

Mark, two thoughts. Idle is too low so it fine in neutral but too low in gear. Idle mixture is too lean, would idle fine without load but would be lean when loaded. Hope this helps. Mike

|

|

By oldcarmark - 15 Years Ago

|

|

Hi Mike! I have reset both.I am thinking now maybe the secondarys are not fully closed after sitting all winter.Going to check this morning.

|

|

By oldcarmark - 15 Years Ago

|

|

OK the secondaries are closed.Any other suggestions?

|

|

By John F - 15 Years Ago

|

|

Pull the float bowl and metering block to see if power valve is leaking by.

|

|

By Nathan Soukup - 15 Years Ago

|

|

Also go ahead and blow out the air bleeds,they might have some dirt in there.

|

|

By oldcarmark - 15 Years Ago

|

|

Still no solution to my problem.I have blown out the passages,adjusted the mixture screws which both work as they are supposed to,upped the idle speed to the point where it cant be shifted into drive(too fast).I dont hear or see any vacuum leak.No excess fuel fumes indicating a leaking power valve.It just shuts off basically when I shift it into drive.It will idle in drive if I use the brake and gas to hold idle speed higher.4160 Holley.Anyone else have an idea.Runs great in all other respects-just wont idle in drive.

|

|

By PWH42 - 15 Years Ago

|

|

Mark,back your timing off a little and try it.I know the general consensus is that the Y likes a lot of advance,but with stock engines I've had some idle issues with as much advance as you are running.

|

|

By YellowWing - 15 Years Ago

|

|

Mark, with engine idling check the temperature of each exhaust port if you have a temp gauge or, with a WELL insulated pair of pliers remove on plug lead at a time. Cylinder running cold or no drop in RPM with plug lead removed indicates a problem on that cylinder. Could be caused be bad plug or lead, vacuum leak (especially if more than one cylinder), one bad idle circuit or even a bad cylinder. This test just gives you more info to work with. Helped me find vacuum leaks on two different friends cars in the past two months. Also you just installed power brakes, another chance for a leak. Mike

|

|

By oldcarmark - 15 Years Ago

|

|

Thanks Mike and Paul.Good suggestions.Perhaps I have tunnel vision focusing on the carb.I will try again tommorow.Appreciate the input.

|

|

By pegleg - 15 Years Ago

|

|

If you have the distributor hooked to ported vacuum, the idle speed may be low enough that you lose the signal when the transmission pulls the RPM down. In gear. Make sure this 12 degrees is with the vacuum disconected.

|

|

By Nathan Soukup - 15 Years Ago

|

|

Try the check valve on the power brake booster,maybe there is a leak?

|

|

By Hollow Head - 15 Years Ago

|

|

Faulty torque converter in the transmission ?

|

|

By oldcarmark - 15 Years Ago

|

|

Hello Ted! Thanks for having a look at my problem.I spent a couple of hours today checking some things.I pulled each plug wire with motor running.All cylinders slowed the RPM when wire removed.Some cylinders seemed more affected and #4 didnt really notice a difference.Ran a separate new wire and changed plug to a known good one.The plug is firing just doesnt seem to make much difference in motor running.Pulled the valve cover and both valves are operating.I dont have a compreesion gauge but used my finger in the hole and there is a good blast of compression.I have to assume that cylinder is working.All plugs are dry and a nice tan color.100 miles on motor.Fuel is 1/2 stale and half fresh.Not smelling rich at tailpipe.Mixture screws will kill motor and seem to work fine.Its a 8007-0 390 cfm.Late distributor with Accell conversion.Ported carb vacuum for distributor.Vacuum line disconnected.Power brake check valve is working.Plugged it and it made no difference just to be sure.Vacuum reading is steady 18 at full time port in base of carb.I turned timing down to 6 BTDC from 12.No difference.Its hard to get a vacuum reading in drive because it just basically quits unless I hold the gas down with the brake. This is the original Fordo.The only other thought I had is the convertor sat empty all winter but the trans shifts fine so I dont know if that could still be the problem.Any suggestions appreciated.It starts fine and runs great and sounds good as long as its in neutral.Valve lash is set at .019 cold and all valves are fully closing.

|

|

By oldcarmark - 15 Years Ago

|

|

Hi Ted I did a little more today.Checked fuel levels.I set them to where Holley recomends.Dry set primary float to 7/32 inverted.Secondary to where fuel is just dribbling out the site plug.Blew out air bleeds etc.Tightened carb screws(not much).Regapped plugs to .032.With a little fiddling it will idle in drive(rough).The vacuum drops from 18 in neutral to 13 in drive.The idle speed is at the point where the ported vacuum is exposed and advances the timing.Reset timing to 12 BTDC.I dont think there is a problem with the convertor.Is this possibly an ignition problem(weak coil maybe?)In neutral it runs fine.In drive it just wont run worth****.Appreciate your help.Thanks Mark

|

|

By oldcarmark - 15 Years Ago

|

|

Did some more today.Used a propane torch to check for leaks.Nothing.Changed the coil.No better.Just refuses to idle in drive.How would I know if the convertor is the problem?What would have happened over the winter sitting empty?Running out of ideas on what is wrong?Anybody have any input?Thanks

|

|

By Daniel Jessup - 15 Years Ago

|

|

I just reread your posts and it looks as if the car runs fine in drive under power or WOT, but it just won't idle worth junk, right? The idle carb passages being blocked in some way gets my vote. In N with no load, there is enough fuel (especially being able to manipulate the idle set screws as needed), but under load, not enough fuel can pass through those idle passages to give enough "juice" to the motor. Dan Is there any way you have another Y blocker in the area with which you could put some heads together, or maybe borrow a buddy's carb to see if it is indeed the problem?

|

|

By PWH42 - 15 Years Ago

|

|

Mark.........Does it die instantly as if you had turned off the key or does it do a slower death as if it's out of fuel?

|

|

By aussiebill - 15 Years Ago

|

|

oldcarmark (4/28/2010)

Did some more today.Used a propane torch to check for leaks.Nothing.Changed the coil.No better.Just refuses to idle in drive.How would I know if the convertor is the problem?What would have happened over the winter sitting empty?Running out of ideas on what is wrong?Anybody have any input?ThanksMark, could be anything but if it was me i would give it a little more advance, reset idle and mixture settings then try it, can you be certain the 12 deg timing is accurate; that the pulley mark is true. just a suggestion and look forward to sucess.

|

|

By oldcarmark - 15 Years Ago

|

|

Thanks for the suggestions everyone.Something that has been suggested by a couple of people is that the camshaft was installed one tooth retarded.I was very careful about getting the timing marks correct but anything is possible I guess,I am going to get hold of a compression gauge and do a test.As I understand it compression considerabley lower than specs evenly across all cylinders could show that this is the problem.I cant understand how it can run so well in neutral and like crap in drive.Will let you know what I find.Thanks

|

|

By oldcarmark - 15 Years Ago

|

|

Thank you Ted! Sounds like the same symptoms I am having.I am going to do a compression test just to see if anything is obviously wrong like the cam gear being out one tooth.Hope not because I was real careful about making sure it was right before going further.Appreciate your input.I do not think it is a carb problem now after checking it over.Adjusting the mix,speed or timing has had absolutely no effect.Looking for something else.

|

|

By Y block Billy - 15 Years Ago

|

|

Low compression would cause these symtoms, you say its a fresh rebuild, what did you use for oil to break the engine in? the incorrect oil and your rings may not have seated yet. Was it a known engine builder? are the cylinders true? Do you have another carb to try just to rule that out, it doesn't sound like the carb at this point but its worth a shot if you have one or can borrow one. Just a thought, hope you get it sorted soon, that would bug the crap out of me.

|

|

By marvh - 15 Years Ago

|

Sorry for a long winded spiel however here is some ideas.

I don't think the converter is the problem unless it got damaged during engine installation by not having the splines engaged or by using bolts to draw the transmission to the block. Mark, given that you did the rebuild I think likely this is not the case but for other readers it is good info and a checklist

One should have felt the converter drop three times onto the transmission, first into the stater, then the pump drive and then the impeller spline. When fully installed the converter should have been below the bell housing surface slightly if all splines are fully engaged and about 1/4" plus clearance to flexplate when bell housing is bolted to the block. Did you add a couple of litres of trans fluid in the converter before installing on transmission after draining. This helps to get the converter primed.

To check the idle/converter issue I would leave the car in park and turn the idle adjustment screw on the carb out to lower the engine RPM to about 450-475 RPM which is about were idle is if in drive with your foot on the brake. If engine still has rough idle or dies likely not a converter problem, to further check if converter problem disconnect drive shaft and slip a spare trans yoke in place so oil does not leak out, place in neutral and start engine again at slow idle. If still rough and stalls further proof not converter problem as converter now has no drag.

I think likely something has happened to the carb over winter in that a gasket has shrunk or a piece of dirt or metal has gotten somewhere not supposed to be. I would get a rebuild kit and rebuild the carb or borrow a known running carb from a friend for a test.

I have found on the y-blocks if the compression is low rough idle is very susceptible to valve lash adjustment, check setting and open valves to 20 thou.

You said the engine was rebuilt. Did you have the heads done and valve guide clearances checked as worn guides will give rough idle as the valves will not seat themselves properly always and hold the valve partially open. This problem is more pronounced at an idle. It does not show at higher rpms as the valves seem to centre themselves easier.

As others have said low compression could be an idle effect due to timing chain out one cog or camshaft needs to be advanced.

I just had to advance the camshaft on my fresh 312 as it had poor idle and poor low end power. Advancing the cam brought the compression up to 160# across from originally 130# and smoothed the idle out. Crappy weather has not given me a chance for a test yet

I just had an experience on a 57 yblock (Autolite carb) that had a stalling idle issue due to the carburetor arm was ever so slightly loose on the butterfly shaft, you had to grab and twist to find the looseness. When one adjusted the idle speed screw RPM would hold steady until you put it in drive then the jolt would turn the shaft inside the arm causing the butterflies to close dropping the RPM's as the linkage held steady the idle would be rough and stalling . I had to peen the end of the throttle shaft to tighten the lever.

You can check that also.

Ted, you probably have checked this already, just my thoughts on the problem

On the teapots I have seen rough idle issues on account of a damaged o-rings on the brass fuel inlet tube that goes between the carb base and the float bowl. When the machining happened for the inlet tube on the carb base a sharp edge was left which will shave or cut the o-ring and a leak will develop. I take a knife and made a slight chamfer to prevent cutting the o-ring, then lubed the o-rings for easy slip. If this o-ring is leaking fuel will drip into the secondaries.

Fuel will also leak in the secondaries and cause similar problems if the gasket is leaking at the needle valve cover. The original gaskets were copper and if not annealed leaks often happened. Today they are using composite gaskets. I use a socket to tighten as an ordinary screwdriver does not tighten it sufficient. One of the T bird suppliers is reproducing this cover with a redesigned gasket to stop this needle valve leak problem

marv

|

|

By oldcarmark - 15 Years Ago

|

|

Thanks Marvh.I will look into a couple of your suggestions.Regapping the valve clearance to .020 is easy to do.The machine work on this motor was done by a local man who has been doing this for years and years.He also assembles complete motors as part of his services.He has done many Y-blocks over the years and actually had a finished 312 on an engine stand when I took mine in for work.I trust him that the work that needed to be done was done if required such as the valve guides(which were not done).I supplied a complete set of new quality US made valves and he did exhaust valve seat inserts and machined the guides for better stem seals than the stock ones.I got 8 of the bigger 1.92 intake valves as replacements. Just curious-is there a downside to advancing the camshaft as you have done?Did you just go one full tooth or did you use an offset key?By the way the new replacement cam I used is a stock grind from Clevite.Hopefuuly it is correctly made as I would have no idea how to check it.Thanks for taking the time to give me your suggestions.

|

|

By marvh - 15 Years Ago

|

Mark:

I used a Rollmaster chain which is index-able. I ended up advancing the camshaft 4 degrees. That smartened up the low end torque problem, increased the compression by 30# and increased vacuum about 1" Hg. I have not had a change to hook on the trailer for a good test due to bad weather, it hailed week ago Thursday night with lots of lightning, then on Friday had snow to nearly a whiteout, then very heavy rains and high winds all week. Those fellows from Montana can stop sending us their unfavorable weather. Oh well could have been worse as Calgary got. There were still snow drifts south of Lethbridge yesterday and the Sweetgrass hills in Montana were all snow covered.

As to down side of advancing the cam I guess one could go overboard and end up with lots of bottom end torque with the running out of power at too low RPM's and no top end power or speed.

|

|

By Fordy Guy - 15 Years Ago

|

|

Well, I've been following this thread from the beginning and have seen all of the troubleshooting ideas possible from the best troubleshooters on the site and nothing has seemed to help. If I could humbly throw in my two cents worth and ask Ted and the rest of the guys that work on automatic transmissions if there is a vacuum circuit in the trans that would be pulling to much vacuum when it is dropped in drive, like a leaking valve or whatever . I'm not a automatic transmission guy but that is about the only place that hasn't been mentioned yet. If there is vaccum to the modulator valve and servos, just maybeeeeee-. Good luck on your witch hunt.

|

|

By oldcarmark - 15 Years Ago

|

|

Good suggestion BUT the Fordomatic in 51-56 and later I think maybe to 59 are all mechanical.They dont have a modulator valve and no vacuum connection to the motor.I have used a propane torch(unlit) to check around the intake and carb and found nothing leaking.

|

|

By Fordy Guy - 15 Years Ago

|

|

Wooops, now I know why it was never brought up, sorry.

|

|

By oldcarmark - 15 Years Ago

|

|

No need to apologize.On any vehicle that does have a vacuum mod valve it is a common item to fail and cause a vacuum leak.The Fordo uses a link from the accelerator linkage to control the fluid pressure (shift points) in the transmission.

|

|

By crenwelge - 15 Years Ago

|

|

This is just a wild guess, but I guess you have tried everything common. Years ago the hose going to the heater control got hard as a rock. Every time I would shift gears, the engine would move and cause a vacuum leak. I didn't figure it out until the first cold spell and I couldn't get any heat. It cost several $5 bills and the embarrassment of seeing tail lights.

|

|

By oldcarmark - 15 Years Ago

|

|

Hello Kenneth! I have the other heater type with the 4 hoses and the valve on the firewall with the cappiliary tube.Good suggestion though.

|

|

By Rods - 15 Years Ago

|

I have been following this as well. My 57 bird, with an edelbrock 1405 just started doing this.

I had taken it to shop to have the carb adjusted because it would not start very well and had a lack of power. They adjusted the timing, and carb. Now is starts right up, and runs with power but dies when you put in gear just like your saying...Shop thought the converter might be bad as well but when I spoke to Concours they said very unlikely as they were pretty much tanks regarding construction. He also thought a new carb kit might help. So the problem might not be a carb issue? Not sure if that helps or muddies the water. I was going to try the propane trick but I can see you did that already. Could the resistor from the coil have any affect on this?

Rod

|

|

By oldcarmark - 15 Years Ago

|

|

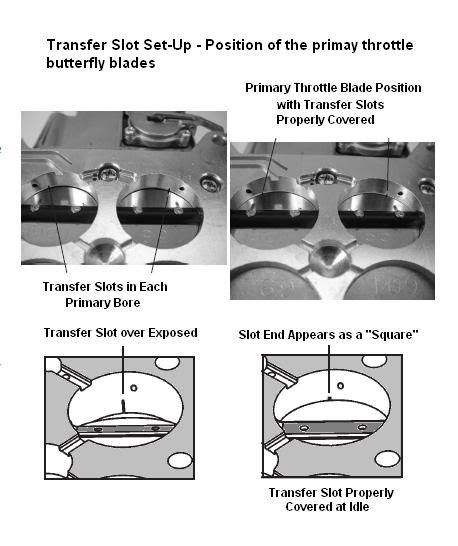

I talked to 2 tranny guys familiar with the Fordo and both said the same thing-not transmission related.Steve(Greenbird56) is helping me to setup the carb and timing better and we are having some success.Much better but still have more "tweeking" to do.One thing that has helped is taking the carb off and closing the primary throttles to where the "transition" slot is visible below the throttle plates as a "square".Once that was adjusted I have been using the seciondary throttle plates to adjust idle speed.If you take a look at your carb below the vacuum control for the secondaries is a threaded hole in the carb base.Its a 8-32 machine thread.If there is allen head screw in there now you can use that to open the plates slighly to set the idle speed.No more gas is added just air.I got an 1 1/2 8-32 machine screw and double nutted the head and added one more to lock the screw against the base once I had the speed set.I can access the screw fron under the carb base.Steve says some cant because of the spacer plate.In that case you have to adjust the screw fom on top-real pain.If you open the primary throttle too far you are adding more circuits than should be in play.I have always thought the speed must set from the primary plates only but this way Steve has explained works.I am also working on the timing.I discovered the vacuum advance is only adding about 4 degrees advance even with 14 inch vacuum.Should be more like 10-12.Also using fulltime vacuum instead of ported so the vacuum advance works right off the bat(gives more idle speed without touching idle speed screws).Going to readjust the vacuum unit to give proper amount of advance.As I said I am still working on this but improvements have been made.Keep you posted.Should mention I have a Holley carb.Dont know if edlebrock is similar.

|

|

By YellowWing - 15 Years Ago

|

|

Mark, could the engine be idling on 7 or even 6 cylinders? If so you would still be able to get the engine to idle just fine by raising the idle speed screw (reason for more of the transition slot showing), but when it is put in gear the load would now be spread across fewer cylinders 6 instead of 8 and the engine would die. With the engine idling in neutral and a pair of WELL INSULATED pliers remove one spark plug lead at a time and see if all cylinders cause a similar drop in power. Check only takes a couple minutes and could lend some insight. Mike

|

|

By oldcarmark - 15 Years Ago

|

|

Hi Mike! I did try that.I did notice a real difference in most cylinders except hard to notice on 4 and 8Maybe because they are firing next to each other in firing order.t.I replaced the wire and tried it.Didnt notice much change with wire off.I have an accurate Snap-on dwell tach coming and will be able to tell better.Also replaced the plugs with new ones.All plugs are showing normal color.Timing light on all cylinders shows firing so........

|

|

By aussiebill - 15 Years Ago

|

|

oldcarmark (5/18/2010)

Hi Mike! I did try that.I did notice a real difference in most cylinders except hard to notice on 4 and 8Maybe because they are firing next to each other in firing order.t.I replaced the wire and tried it.Didnt notice much change with wire off.I have an accurate Snap-on dwell tach coming and will be able to tell better.Also replaced the plugs with new ones.All plugs are showing normal color.Timing light on all cylinders shows firing so........Mark, keen to see you sort this problem out, have you tried vacuum gauge on engine? Check reading in nuetral then in gear, seems like low power in back cyls, vac leak? regards bill.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

I'll welcome a correction by Mark if I mis-state this but what seens to be happening is that the engine is down on torque at low rev's when the auto trans is engaged. That causes a "stall". It is a new rebuild, may have a good bit more internal drag than it had before the refresh. He has tested his spark system several ways - and it is making sparks - but maybe not at the right time. To build the required torque, the engine needs air - and the 390 CFM carb has very small primaries. So his inital response is the same as the rest of us - turn up the idle screw. As a consequence, the blade is wrongly positioned on the idle transfer slot - she was just about operating on the main jets. Holley has a manual for this carb that suggests opening the secondary butterfly to get additional idle air.  This not only works well but beats the daylights out of the old "drill holes in the butterfly" solution. The secondary bores have fixed flow idle weep holes - this outfit just needed some air. Holley has some really poor directions in the manual for setting the idle transfer slot position - so we used the one recommended by BG for the Demons.

This seems to have gotten him some idle control and additional torque (adding air to the existing fuel flow) - but now he has found some discrepencies in the way the vacuum advance pot is behaving. It is very erratic and may have a hole in the diaphragm or something like that.

|

|

By oldcarmark - 15 Years Ago

|

|

I think you pretty well got it right Steve.It is definetly better than I had it running.Besides what the Holley manual says about positioning the throttle plate to cover most of the transfer slot I have found that instruction repeated on several of the websites I have surfed looking for info on setting up carbs and timing.I will have a better idea of what is going on when I get that tach/dwell in my hands.As was suggested awhile back I dont know what the speeds are now in neutral and drive.Just guessing.I will also be able to tell IF all cylinders are in fact firing as the RPM should drop on each one as the plug wires are pulled off.AussieBill's suggestion about the vacuum gauge is good.I have used it,Idling in neutral gives rocksteady 18.Drop into drive its about 13-14 and steady.I think if there was a misfiring cylinder the vacuum would not be steady.In drive the vacuum advance is only advancing by about 3-5 degrees.It should be in the area of 10-13.I will be adjusting the tension on the advance and get it working better.I really think my trouble is a combination of several small adjustments.However I saw the post yesterday from another member(rods) who is experiencing the same thing with a NOT new motor.Maybe if if get mine sorted out it may help with his.Thanks for all the input guys!

|

|

By Rods - 15 Years Ago

|

As I have been following your posts and have been trying to do the same things to see if I can find a solution. The edelbrock is simple enough to adjust but something is just not right. I do not have all the gauges to verify things but i know if I drop idle to 850rmp the beast will stall. What are you idling at? I think you mentioned if you 2 foot it, it will keep running, same here. I apologize if i missed it but have you tried a different carb? That might help to determine if it is a carb issue or a timing issue. I was not sure if you mentioned that. That would be interesting to see what impact that would have...

My idle is at 6* on the timing but I have trouble keeping it running when I disconnect the vacuum. Does yours stay running?

|

|

By speedpro56 - 15 Years Ago

|

|

6 degrees btc is toooooo low, move it up to at least 12 degrees and see if that helps. Fords yblock timing was just to low with 3 to 6 degrees depending stick or automatic.

|

|

By oldcarmark - 15 Years Ago

|

|

You should find out what they did to it at the shop you took it to.They fixed one problem and created another by the sounds of it.

|

|

By oldcarmark - 15 Years Ago

|

|

Hello Ted. I was reading an article about timing and carb adjustment.The author states that the vacuum advance should be at full advance with vacuum at 2in less than the lowest engine vacuum reading which in most cases is idling in drive.If the engine vacuum reading for example is 14 in drive and the particular advance unit on the car does not get to fully vacuum advanced position until the reading is 18 the advance unit is in the midrange of advance and CAN cause timing to be unsteady at idle in drive.I dont know how to post a link to this article but if you do a search on the internet for "distributor timing and theory-part 1" it should take you to "hotrodder.com.Its a 2 part article and is one of the best I have found to explain timing and advance.If someone can post a link its well worth reading.Explains for one thing why you should be using non-ported(fulltime manifold vacuum).When I was checking the vacuum advance on mine at idle in drive it is only advancing about 3-5 with manifold vacuum applied.Should be at least 10+.I will get in there with an allen key and readjust it.

|

|

By YellowWing - 15 Years Ago

|

|

Here is the link. Mike http://www.hotrodders.com/forum/distributor-tuning-theory-part-1-a-59033.html

|

|

By oldcarmark - 15 Years Ago

|

|

Thank you Mike!Its well worth reading I think.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Too much GM junk in there don't you think????? You guys are going to get Ted all jacked up over the "ported" vacuum again!!!!! http://www.fordmuscle.com/archives/2000/03/timing/

|

|

By oldcarmark - 15 Years Ago

|

|

Steve! If you ignore the fact that its GM the theory this guy puts forth applies to all makes in part 1 anyway.Interesting that GM made all different advance units depending on application.I dont think I have ever heard Ted wound up.Theres a 1st time for everything.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

I'm pulling your chain Mark - any ideas I can adopt to make my outfit run the way I want - I use them.... Here is another good article - and the guy writing it is the real deal... http://www.gofastnews.com/showthread.php/604-Distributor-Curve-Science-Simplified

|

|

By Rods - 15 Years Ago

|

|

What is your timing when at idle without the vacuum on?

|

|

By oldcarmark - 15 Years Ago

|

|

I am setting mine at 12 BTDC and working with it from there.The factory specs of 4 or 6 BTDC are not enough.

|

|

By Ted - 15 Years Ago

|

|

How old is the fuel? Does the exhaust smell ‘fuel rich’ at idle? Can the engine be killed by screwing the idle mixture screws in all the way? Are the screws that attach the baseplate of the carb to the main body tight? What’s the list number on the carburetor? What distributor? Points or electronic ignition? If points, what point gap? Ported (timed) vacuum to the distributor or full vacuum? Is the ignition being timed with the distributor vacuum hose hooked up or unhooked and plugged. Power brakes? Where is the vacuum reading being taken? Is the vacuum reading steady? What’s the vacuum reading of the engine when in drive? What year transmission? Does the transmission have a modulator valve? What valve lash setting is being used?

|

|

By Ted - 15 Years Ago

|

|

Assuming this problem is not related to the torque converter, the top item that comes to mind based on what you’ve said so far is to raise the carb float level and see if that helps. Secondary float level is also important as there is a fixed idle circuit on the secondary side of the carb and a low float level there can affect that particular circuit. If you have the carburetor off, then make sure the base plate itself is tight to the main body. While looking at the carb, take some carb cleaner and high pressure clean the small air bleeds on both the primary and secondary side of the carb. Although some of the other symptoms are not pointing to it, I’ll suggest checking that the fuel discharge nozzles sitting within the venturi centers are physically tight to the carb body. Just take a finger and see if you can get any 'wiggle' out of them.

|

|

By Ted - 15 Years Ago

|

|

Mark. There’s a 1956 Ford with a 312 and Ford-O-Matic in my neck of the woods that’s doing similar as yours. It’s a fresh rebuild and the owner can’t say if the problem was pre-existing before he got the car as He had to rebuild the engine as soon as He purchased it. The 312 has a Teapot Holley with the Isky E4 camshaft ground on 112° lobe centers and 5° advance on the camshaft. Valve lash is 0.019”. The distributor is the late model distributor and the Teapot carb has been modified so it has only ported vacuum with the venturi vacuum assist and spark valve portions being disabled. Ported vacuum at idle is zero so that part is like it should be. Manifold vacuum is good at idle (17½”Hg at 850 rpms) and now starts and idles without issue. When warm, the engine starts right up by just reaching in through the door window, no extra help with the accelerator is needed. The car drives perfectly; it’s just the dying issue when put into gear that’s baffling. When the engine was initially started after the rebuild, the carburetor did not idle well and besides the engine smelling rich at the exhausts, the idle speed surged lightly up and down. Putting a very small wire in each of the idle feed restrictions in the Teapot cured these idle issues as well as restored control to the idle mixture screws. But the engine still dies almost immediately when put into either drive or reverse. But there is one small nuance in this dying issue and that is if the transmission is put into gear immediately upon starting the engine, it does so without killing the engine. It’s only when the engine is started and allowed to level out for a few seconds before putting it into gear does the engine die. With this particular clue in mind, the problem is pointing towards the converter. Prior history on the transmission in this case is unknown so it’s the logical place to start. It’s unknown if the transmission and/or converter is the original to the car as the engine was not. The tranny had new seals installed since it was acquired and that’s about all the history that’s known. In this case the converter can come apart quite easily but it’s still going to be a job in just removing the transmission so that the converter can be examined in more detail. The stall speed could simply be too low but it’s going to take someone with an intimate knowledge of converter design to be able to look at this and spot the problem if this is indeed where it’s at.

|

|

By Ted - 15 Years Ago

|

|

oldcarmark (5/18/2010)

.....In drive the vacuum advance is only advancing by about 3-5 degrees.It should be in the area of 10-13. I will be adjusting the tension on the advance and get it working better.Rods (5/19/2010)

My idle is at 6* on the timing but I have trouble keeping it running when I disconnect the vacuum. Does yours stay running?By the book, the idle speed in neutral should not change when the distributor vacuum advance line is disconnected when the engine is idling. If it does change, two possibilities include the vacuum line is hooked up to a direct vacuum source or the carburetor primary side throttle blades are open too much thus exposing the ported vacuum hole within the carb’s throttle bore at idle.

|