|

By 1960 Edsel 292 - 15 Years Ago

|

hello guys. let me introduce myself.

my name is leonard from south florida. the edsel is my buddies car, and he aint much of a mechanic, so i have some questions for you all since i am the one working on his car.

its a 1960 edsel rager with a 292 v-8 and 2 speed transmission. the odometer reads 98k miles,a nd we seem to think its original. the car is in pretty darn good shape, with a repaint, original interior, etc.

it has a 2bbl holley carb thats about 2 years old installed by the previous owner.

its been having a slight stumble/bucking problem while at cruising speeds around 30-60 mph. runs fine while acceleration up to that speed, but once you hold it steady it will buck.stumble. float level is good, we took the needle and seat out and blew compressed air on the seat, but still getting the stumble. yesterday it was back firing through the tail pipes, so we popped the new looking distributor cap and found the points to be burned and the inside of the cap looked slightly corroded, so we put a new cap, rotor, condenser and points in it this morning. got rid of the back firing problem but still stumbles/bucks.

do you guys have any suggestions where to start next ?

i can hear some valvetrain noise, like lifters, and a buddy said that is normal because these engine are solid lifter engines ?

after a cruise when we pop the hood, i can see some smoke coming from the oil fill cap, and i dont think thats good, probably blow by, right ?

next sunday we will do a compression test, and i was wanting to know what is normal for the 292's ?

also, we are looking for an automatic transmission filter for it, but nobody has one. when we were at autozone today and we told them edsel for the tune up parts, of course they looked at us like we were from mars. LOL. noting for edsels, so i told them 1960 fairlane, and they had the tune up parts for that, and they were the same. but cant seem to find a trans filter. do you guys knwo the model of his transmission ? all i know is the standard c-4, c-6 and fmx ford transmissions, but dont know anything about an old 2 speed thats in his edsel.

any and all help would be greatly appreciated guys.

thanks

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

The trans is a 2 speed Fordomatic.If you cant get parts locally try Macsantique auto.com.If the filter is not too bad clean it and get a new gasket from Autozone.Fordo 2 speeds are all the same.If you take off the rocker covers and run it do you see oil comming out the rocker shaft at the end(overflow tube)?I am not sure about the Edsel but is there a cannister on left side of motor ahead of the oil filter(roaddraft tube)?There is a filter in there that is likely plugged completely.Take off the centre bolt ,remove can and check filter.There is no engine ventilation as air goes in oil fill cap and out the roadrft tube.Very likely cause of smoke.start there and let us know what you find.Compression should be somewhere around 150 on a new motor.More important is how even are the numbers.Valve clearance cold is .019.Turn motor and do one cylinder at a time starting with #1 with motor at TDC and rotor pointing to"#1 cylinder on distributor.CC rotation.Firing order 15486372.Cylinder 1-4 passenger side from from to back.

|

|

By 314 - 15 Years Ago

|

|

you trouble seems like the carb.take it apart and give it a good cleaning blowing out all passages.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

wow guys, thanks for the info, especially oldcarmark.

i cant remember what all is under his hood, but i will check it out next weekend. not sure how far we will dig into it valve cover wise, but will hopefully do the compression test and check the plugs for sure. (i got me a 57 chevy truck that keeps me busy).

the 2 bbl holley is kind of new, but im suspecting it might be getting some rust from the tank maybe. we really need to change both fuel filters also.

is there a possibility there is some rust/junk in one of the jet holes ? i guess we need to take the bowl off and dig a little further.

thanks again guys for the info. these old car websites are awesome.

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

I think its a good idea to check the fuel system.Change the filter(s).How old is the fuel in the tank.If its over 2 months old it is likely part of your trouble. To check compression remove all plugs and have carb throttle fully open.Should be done with motor cold.Each cylinder should get about 4-6 compression strokes.As far as valve train noise-you will hear the valves when first started.Should lessen as motor warms up.Let us know how you make out.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

thanks oldcarmark.

fresh fuel for sure, since he drives it just about every weekend. not sure of the tank inside condition. it has 2 fuel filters on it, i think one before the pump and one after.

he does add some lead additive to a full tank. is that recommended ? gets it at autozone.

couldnt find my compression tester but i think another buddy has one we will borrow.

will let you know what we find, hopefully nest weekend.

leonard

|

|

By Ted - 15 Years Ago

|

|

1960 Edsel 292 (8/15/2010)

.....its been having a slight stumble/bucking problem while at cruising speeds around 30-60 mph. runs fine while acceleration up to that speed, but once you hold it steady it will buck.stumble. float level is good, we took the needle and seat out and blew compressed air on the seat, but still getting the stumble. .......so we put a new cap, rotor, condenser and points in it this morning. got rid of the back firing problem but still stumbles/bucks.Checking the ignition timing curve with a timing light while slowly revving the engine up and down (with transmission in park) may help in determing if the timing curve is smooth and functioning correctly. In lieu of this, you might try disconnecting the vacuum advance and driving it. If the stumble/bucking issue disappears, then put your focus on the distributor advance system.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

thanks for the tip ted. thats easy enough to try, unhooking the vacuum line.

what should the timing be at idle ?

leonard

|

|

By Ted - 15 Years Ago

|

|

Anywhere between 8° & 14° initial timing at idle with the vacuum advance unplugged will suffice for a test drive. And Welcome to the site!

|

|

By 1960 Edsel 292 - 15 Years Ago

|

thanks for the timing info ted.... hopefully we will check it out this sunday.

leonard

|

|

By 1960 Edsel 292 - 15 Years Ago

|

guys, tomorrow morning we are gonna check the compression and distributor advance and timing.

while we have all the plugs out, i want to check the gap.

what is the recommended spark plug gap for these plugs ?

also, when i changed out the points last week, i measured .015 on the old points, and put that gap back with the new set.

what is the recommended points gap ? on my 1970 mustang i use to go with .018, or a match book cover,

thanks

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

Plug gap .032-.036.Points .017-.018.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

thanks oldcarmark. heading over there right now for the compression check and the unhooking of the vacuum advance to see how she runs, if the rain hold off. i will report when i get back

leonard

|

|

By 1960 Edsel 292 - 15 Years Ago

|

|

ok guys, im over my edsel buddys house right now. here is what we found. compression is at 150psi on 4 cylinders, one cylinder at 155 one ant 145, one at 140 and one at 130. how does that sound ? they seem to be right in the 150 range, with the lowest at 130. checked all the spark plugs while they were out, and found most of them to be at .050 gap. i closed them all up to .035. the plugs are motorcraft BSF 82C, and they seem to be burning hot. they have a burnt spot on them in one area. not sure if the heat range is correct for this engine ? could this also be a condition of running too lean ? need some help in this area. ok on the timing. couldnt remember if i should check initial timing with the vacuum advance unhooked from the distributor ? we checked it hooked up and at idle, and the previous owner has a red aint mark on 6*, so im asummming the PO wanted it at 6*. well, at idle with vacuum advance hooked up it looks to be about 20*. car starts right up and idles well. im gona go out there now and see if unhooking the advance will get the initial lower than the 20* its running at with it hooked up. ok, i now see that ted said between 8-14* with the vacuum unhooked. going out there now to unhook the vacuum line and see what we get. just wanted your thoughts on the compression and the spark plug condition. going for a test drive afterward. i will post the results. leonard

|

|

By oldcarmark - 15 Years Ago

|

|

You have pretty good #'s on compression.There should be no more than 10% difference between high and low so you are just out of that range.155-10%=140.Your lowest is 130.The plugs are correct# I believe.Regapping to specs or replacing with a new set and driving it should give a better idea of lean or rich.I think you will find it is OK.As you remembered the initial timing is set with line off and plugged.With full manifold vacuum applied timing will advance as you already noticed.I would experiment a little with the timing and try around 10-12 initial and see how it starts and drives.You might also check the valve lash for .019 clearance cold.A couple of tight valves can effect the compression #'s as the valves wont fully close if too tight clearance.You can set valves one cylinder at a time.Start at #1 at TDC and turn 1/4 turn of the damper and set next cylinder in firing order.15486372.Sounds like you are becomming a "Y Guy".

|

|

By 1960 Edsel 292 - 15 Years Ago

|

ok guys, here is what we found on the timing.

with the vacuum advance hooked up we got around 20* initial.

with the vacuum advance UNhooked we got 0*.

with the vacuum line unhooked from the distributor, and we slightly revved the engine up in nuteral, we were getting some slight backfire through the tail pipes, so we did not try and test drive it unhooked.

while test driving it slightly stumbles on take off from a dead stop, runs so smooth while accelerating up to speed, say 40-50 mph, but once at speed and trying to maintain that speed it still surges a little.

so, should we try and advance the timing to the get the required 8-14* initial with the vacuum line unhooked ?

like i said, right now with it hooked up it looks to be about 20* advanced at idle. the timing tab only goes form 0-10*, so im guessing its around 20* advanced because of the distance its showing up from the end of the timing tab. to me it seems if we do advance it to the 8-14* initial with the advance unhooked, it will then be 28-34* initial with the vacuum line hooked back up.

should the initial timing go from 0* unhooked to 20* vacuum line hooked up ?

i am not a fine tuner type guy thats for sure. i know how to change parts and know how they work, i just cant fine tune a car.

im heading out of the house now for a bit and will check back in later this afternoon.

thanks for all the help guys.

leonard

|

|

By GREENBIRD56 - 15 Years Ago

|

|

You'll get the hang of this pretty quick - this isn't a rocket you're building and those compression numbers are OK for an oldie. Your friend needs to invest in a set of valve cover gaskets - you'll need them before long. Setting the plug gaps back was the right step - and that's on the road to recovery - but what did they look like at each position? Make a diagram or list if you would and number them out. The cylinders of the Ford / Edsel engine are numbered 1-2-3-4 front to rear on the passenger side and 5-6-7-8 on the driver side (front to rear). Make a note of the plug nose condition - compression figures from earlier, hole by hole, etc. It will give you all sorts of clues as you go. When I dragged my bird home - I had four rich cylinders and four plugs lean burned - and the pattern matched their common cylinder feeds out of the intake manifold. The manifold is cast in what is known as a "cross-H" - so that as each successive cylinder fires, it is alternately taking the intake charge from one side of the carburetor and then the other. The four lean cylinders led me to a bad idle feed on one side of the carb - and the other side was set-up over-rich to accomodate it. If that's what you find - we'll figure a way to help you through it. The engine has three ignition advance settings / features. (1) Initial Advance Setting - is at a low (warm), constant idle speed, checked with your light (clean off the marker and marks on the damper). The vacuum line to the vacuum pot should be disconnected and the opening in the carb sealed up to prevent a vacuum leak. Original factory setting for the Edsel could range from 0° to 6° - all of us have found that the upper end is better. When you have things humming - this can be judiciously raised to something like 10°-12° - but don't go there yet. (2) Centrifugal Mechanical Advance - when you rev the engine and watch the timing marks indicated at the damper, they should rise smoothly with rpm. The engine has to have its spark "lead" automatically adjusted as rpm increases to start the fire in the cylinders at an ever increasing rate. If this isn't happening - you'll find the point plate has some holes in it - squirt some WD-40 down below there and see if you can get it to loosen up. Otherwise, the thing will need opened up, cleaned and lubricated for proper operation. Tests of the centrifugal advance are done with the vacuum line to the distributor disconnected and the carb port plugged as before. (3) Vacuum Advance - When the vacuum pot is hooked to manifold vacuum it advances up to a fixed maximum point as full vacuum is reached. Your tests have shown 20° - a reasonable stock performance at elevated vacuum (closed throttle idle). This feature is normally added to the engine to promote economy - and to an extent help reduce operating temperature - but the engine will run without it. Leave this alone for the moment - and get the other two systems to work right - just plug the open port at the carb - the 20° is fine when you need it later. Get these systems working - and you will be a long way toward a successful tune-up.

|

|

By bird55 - 15 Years Ago

|

|

Nice description, Steve - well taught.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

wow. thanks for the info oldcarmark, and agreenbird56, amazing.. how you guys know this stuff to the detail you do, really amazes me.

since the vacuum advance does seem to be working properly, we wills tart off with a new set of plugs and we will set the initial timing to 6* and start from there. as said, it is now at 0* initial with vacuum line unhooked and plugged.

hopefully we will get a chance to do this next weekend, and i will let you guys now what happens.

thanks again for all this valuable info. couldnt do this without your guy's help.

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

Have you checked the centrifugal advance?With the vacuum line unhooked (so the vacuumm advance doesnt work) does the timing advance as you raise the RPM?

|

|

By 1960 Edsel 292 - 15 Years Ago

|

oldcarmark.

yes, i forgot to add that. when we unhooked the vacuum line, and raised the idle, revving the motor to about 2k rpm, yes, the timing did advance a little, not as much as it did when the line was connected.

i actually was surprised it did advance, and didnt think it would/should.

thanks man.

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

It should advance much more than a little.A minimum of at least 20-30 by 3000 rpm.Should change steadily as RPM increases.I have a feeling either the weights under the plate are stuck or the springs are broken or unhooked from weights.Centrifugal advance is independant of the vacuum advance.Vacuum advance moves the breaker plate.The centrifugal moves the cam.You may have to pull the dist and take off the braker plate(2 screws) and have a look at the setup under the breaker plate.Before you do that try turning the rotor by hand.It should turn slightly and then spring back.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

wow. thanks oldcarmark.

im guessing it moved about 6* advanced when we revved the engine with the vacuum unhooked. so thats not enough you say. i think we are heading in the right direction.

when the vacuum line was hooked, it did seem to move a lot when we revved the engine.

im gonna tell my buddy if he wants to try the distributor, i will pull it and he can get it rebuilt, and i will pop it back in. if it were mine i would probably mess with it more, but i got my own classic to play with. LOL.

also, is there a way to put an electronic ignition distributor in the 292 ? if so, who makes them and how bad are they to hook up ?

i got an electronic distributor in my small block chevy in my 57 and love it.

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

Definitely sounds like the centrifugal is not working.You can buy a rebuilt for about $50.00 exchange.Before you buy one have a look at the one you have now.Take the breaker plate off and check the weights and springs underneath.Electronic ignition-Pertronix 2 or Pertronix 3.VERY easy to install especially if the dist is out.2 screws and 2 wires to hook to the coil.Check Ebay for good prices.Rebuilt dist is a Cardone part#30-2808.Application 64 F100 with 292.I seem to recall Autozone had a good price for that.Mr. Gasket sells a spring kit for the Ford distributor. Part#925D.Gives a much quicker advance curve.About $5.00.Works great on mine.The other thought I had is this.The 55-56 distriutors are caled loadomatic because they are vacuum only advance.They dont work very well in the later motors.Is it possible someone has stuck an earlier distributor in this car?.They wont advance at all with the vacuum line off.There are several pics of the later distributor diassembled on this site.Do a search using the "search" box at top of page.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Here is a graphical representation of the typical passenger car Centrifugal and Vacuum Advance Curves - taken from Ford literature in the mid-seventies - but relevant to most all Ford gas engines of "medium" performance.

Distributor RPM is 1/2 the RPM at the crankshaft - so you can see that the 6° additional centrifugal advance (you found when reving the engine) would occur at about 1400/1500 crank RPM. If you haven't got something like that, the internal mechanism is either "pretty stiff" or maybe has some god-awful heavy flyweight springs in there. Have you tried the WD-40 "soak-down" yet? The 20° of vacuum advance you found, could occur (by this graph) with manifold vacuum levels of 10 - 15 inches of Mercury - so that value is reasonable.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

wow. you guys are amazing.

will try some wd-40 first, then since its cheap enough will talk my buddy into a rebuilt distributor.

man, this info in amazing

leonard

|

|

By 1960 Edsel 292 - 15 Years Ago

|

guys, i found a rebuilt distributor at my local NAPA store for 72 bucks.

gonna tell my buddy to get one.

http://www.napaonline.com/Search/Detail.aspx?A=NRD482808_0130785601&An=599001+101960+50087+2087005#

is there anything special i need to know about swapping it on his 292 ? i have pulled tons of dizzys on small block chevys and some 70's small block fords. not sure if there are any surprises on the 292 ?

thanks.

leonard

|

|

By Metal Ghost - 15 Years Ago

|

|

Wow, I'm just trying to soak all of this knowledge up. I'm loving this thread! Sorry, nothing to add to the technical side of this discussion (I'm more of a question asker at this point in my mechanical career!!), but as a side note I would suggest this Mr. Edsel: you should definitely tell your buddy to get on this forum and if nothing else read thorugh all of the responses here as well. Not so that you don't have to help him or so he feels the need to do things himself that are beyond his skill level, but if there's anything I've learned since getting into old cars it's this: it feels so much better to at least have an understanding of mechanics then to always have to rely on someone else. Plus that way if he creates a sign-on, etc., he can come here and ask some questions so next time he hits you up for help he'll have a starting place for you! I know all of my mechanic friends appreciate that! LOL Granted, I suppose you have to enjoy learning this type of thing. Anyway, keep all the good information flowing guys....I'm loving it!

|

|

By GREENBIRD56 - 15 Years Ago

|

|

So...I found NAPA part number NRD 482808 on their site - that looks to be the right one for this application. If you guys can find an old swap meet junker for trading stock, you might save some of the $33 core value so he can keep his original.

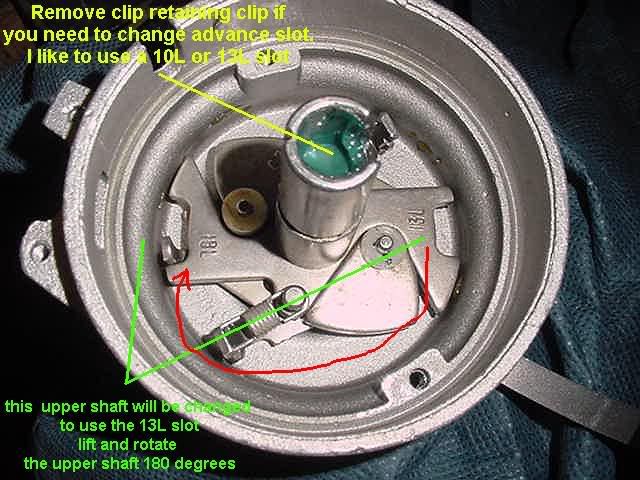

Before you put the new one in - you might find it convenient to have a look at the mechanical advance mechanism while it is out on the bench. The above photo shows the typical Ford flyweight arrangement used on the later distributors. It isn't too difficult to disassemble one down to this level. The pictured unit has two "total advance" limits to choose from....18L and 13L. When the base is engaged in the 18L slot - the distributor can provide 18° of advance (36° at the crank). When it is engaged with the 13L slot - 13° (26° crank). You would like to find it in the 13L slot and if not, its a good idea to put it there. To move one 180° you must remove the little retaining clip (located under the green grease in the picture), disconnect the springs, and lift the upper rotor shaft up to turn it. The little clip has two upward facing whiskers - they have to be spread not squeezed. There is a variation of this pictured rotor shaft that has a 15L and a 10L slot - if that is what you find, I'd say use the 10L. It could be opened to the same length as a 13L with a small rat-tail file - but that is getting ahead.... Here is why you want the limited distributor advance setting - the engine will only tolerate something like 36°-38° of total mechanical advance (that is the initial plus the distributor) under load (with low/no manifold vacuum). You want to put more initial on the bottom (10°-12°) without violating the upper limit. If you were to use the 18L slot - then the initial advance set point would have to be down at 0°-2°. When using the 13L slot, the initial can be 10°-12° (adding some nice low end torque) and not violate the advance limit as the engine gets into the higher rev's. Installing it - the lower end has a hex drive for the oil pump shaft. In some instances, where these shafts don't get a lot of engagement into the distributor - you have to be darn sure the new distirbutor is fully down into the engine well and engaged - or you'll soon be trying to start up with no oil pressure! Rotation is counterclockwise as seen from above.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

wow greenbird56, you amaze me with each of your posts. you know your stuff.

this is great info here for all you guys.

im gonna talk to him this weekend and hopefully he will spring for a new distributor.

thanks for the tips

leonard

|

|

By Ted - 15 Years Ago

|

|

1960 Edsel 292 (8/24/2010)

Is there anything special I need to know about swapping it on his 292 ? I have pulled tons of dizzys on small block chevys and some 70's small block fords. Not sure if there are any surprises on the 292 ?Like most Ford engines that uses a hex shaft for the oil pump drive, care must be taken when intially pulling the distributor so that the oil pump drive itself does not come up with the distributor. Wiggling the rotor as the distributor is being lifted will sometimes help to disengage the drive from the lower end of the distributor.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

wow, thanks ted. wouldnt want the shaft to come up with the dizzy, thats for sure.

might not have a chance to mess with it until next weekend. will let you all know how it goes.

leonard

|

|

By 1960 Edsel 292 - 15 Years Ago

|

ted, my buddy will order the distributor this week, and we will install it next weekend.

how hard is it to get the hex shaft back in the pump, if it does come up with the distributor ?

leonard

|

|

By oldcarmark - 15 Years Ago

|

|

The shaft has a serrated washer which is supposed to be at the correct height to hit the block at the lower end BEFORE the shaft comes out of the pump.If it has shifted or is incorrect hieght the shaft may disengage.Luckily because of a great design the oil pump is external on the side of the block.Not real difficult to unbolt and fix the shaft so it does not come out next time.Hopefully you will not have a problem.If the dist has not been out for a long time you might want to apply some penetrating oil around the base that goes into the block(several times if possible) before you need to get it out next weekend.They get "welded" in place over the years if not moved around once in a while.

|

|

By 1960 Edsel 292 - 15 Years Ago

|

thanks for the info mark.... hopefully the shaft stays put. but, knowing my luck.......

leonard

|