|

By salf100 - 14 Years Ago

|

|

Has anyone made alternator brackets for there 292? I want to use a GM 1 wire unit and want to make the brackets. Anyone have plans or dimensions for this? How bout instructions on the installation of the alternator, particularity what stock wires I can get rid of. Thanks

|

|

By ibuzzard - 14 Years Ago

|

Check out this link,it might work for you.Steve.

http://www.ranchwagon.com/tech/alt/alt.htmmoderator edit - "link fixed by adding a space after it."

|

|

By shakey pete - 14 Years Ago

|

|

look in Charle Mummerts y-blk they sell a nice adapter for a 1 wire delco alternator Shakey

|

|

By GREENBIRD56 - 14 Years Ago

|

|

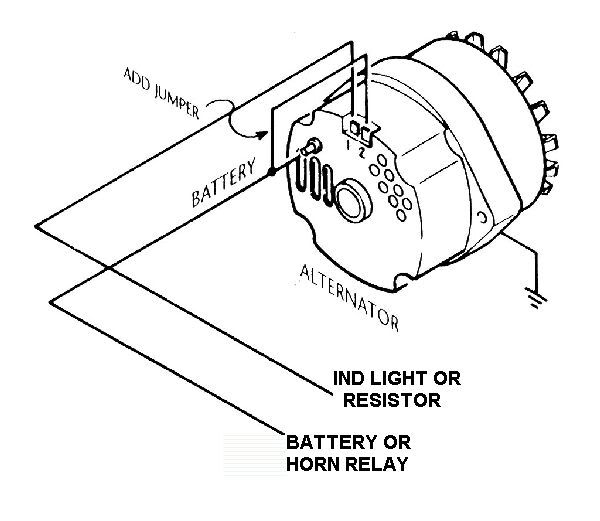

This is the necessary wiring info for a GM "S12" alternator - that has the three wire connection. One of the wires is "jumpered" directly to the output terminal so that it becomes a "two wire" system. Using the three wire set-up gives you the necessary connection to retain use of the "idiot light" - showing the the alternator is not functioning.

These alternators often have a rated output of 100 amps+ - so the main output cable is best routed direct to the battery terminal on your starter solenoid. A piece of #6 welding cable with soldered copper end lugs and some high temp heat shrink tubing for insulation is the best arrangement I've found. Voltage drop is virtually nil - so the volts at the solenoid will be everything the alternator can deliver. The number "2" connection is a sensing function - when voltage at that terminal is "low", it turns on the alternator's internal regulator to produce current. On stock GM applications this sensor line is connected up near the ignition switch so that low voltage at that end of the system is commanding the internal regulator......but...if you provide a high current / low resistance cable to the solenoid as described above, you won't need a separate sensor wire. So it can just be jumpered to the output terminal. The terminal labeled number "1" is held "open" by the alternator regulator when it is actively charging the circuit. When the alternator stops producing volts/amps this terminal becomes a ground - so if there is a switched voltage source (from ignition "on") and an indicator light connected there - it will light when the terminal grounds. Choosing the wrong point to connect the positive end of this wire will kill your battery (the light will be on all of the time). Don't. Power may "backfeed" to the ignition through this wire and cause the sytem to stay running with the ignition switch "off". Use a common "diode" from Radio Shack to make sure that current may only flow toward the alternator - not toward the dash idiot light. At your old voltage regulator there will be a main power wire connection for the vehicle - like a number 10 yellow wire headed back toward the dash. Put a large ring terminal on this wire and connect it to the battery post of the starter solenoid - right beneath the cable from the alternator. That leaves the yellow #10 wire running from the old regulator to the horn relay. An easy way is to power it is with a ring terminal connected to the main post of the alternator - just depends on what is convenient. You will have plenty of current available for the horn(s).

|

|

By shakey pete - 14 Years Ago

|

|

use a delco 1 wire and hook up after market gages oil , temp , charging there is a million 1 wire delco,s around and you can buy a crome body from u.a.p napa they a cheap to repair and work great Shakey

|

|

By Talkwrench - 14 Years Ago

|

|

Hopefully this link works http://www.ranchwagon.com/tech/alt/alt.htm I have just done this with a GM style Bosch alt and it works fine. I had to use a slightly smaller rod so my alignment is not the best at the moment. We found that if using the regulator as point to swap the wires into the "Gen light" stayed on so removing the regulator altogether solved the problem. Total cost for me $4. as I already had the alternator I saved from something else. [Steve Greenbird56 Ive sent you a PM ]

|

|

By carl - 14 Years Ago

|

|

I parted out a y block truck motor that had a alternator on it,i still have the mounting brackets e mail me at CL56VIC@YAHOO.COM if you still need them Carl Ohio

|

|

By salf100 - 14 Years Ago

|

|

Thanks for the tips fellas. I think I'll go with the one wire set up. I'd like to get rid of the regulator and such for a cleaner look. The bracket idea on that link looks straight forward and I'll use that!

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Just be sure and put a big healthy wire on the power lead back to your main harness/battery. The alternator output amperage is high - there is a chart at the site below that shows the wire guage ratings in amps: http://www.powerstream.com/Wire_Size.htm On a one wire system (it will have the jumper I described above hidden in the case) you will want the voltage drop between the alternator output and the battery to be as small as possible. When I was setting up my system, the manufacturer of the alternator recommended that the ratio of pulley diameters (crank to alt.) be three to one. The one supplied with the alternator was too big to get that much ratio (relative to the stock Y-block pulley) and I had to hunt around to find a smaller alternator pulley. Between the relatively slow Y-block idle speed - and the big alt. pulley - the rascal didn't put out anything near what I wanted despite the high amp rating.

|

|

By JeffB54 - 14 Years Ago

|

|

Use a 4 or 6 gauge cable like Fords use off the solenoid from your alternator to the POS batt terminal,usually about $5 at most parts stores,I have done several like that,no problem handling the amps that way.

|

|

By rgrove - 14 Years Ago

|

|

Other thing to keep in mind - depending on what year you are working on you may have a wider belt (5/8"?) than 1-wires usually ship with (1/2"?). If so, you will need to get a different pulley with the wider groove for the belt also.

|

|

By 569104 - 14 Years Ago

|

|

Just an FYI, Alternator output (amps) depends on the load or the demand of your system. Just because you have a 100 amp alternator does not mean it is always putting out 100 amps. It means it can supply "up to" 100 amps of load under normal operating conditions. If the only load your vehicle has is ignition, running lights (head lights, tail lights, parking lights, interior light etc.), and a heater fan for example a 100 amp alternator may never put out 100 amps under normal operating conditions. If you have a winch, auxiliary lights, A/C, high output stereo, air compressor, electric windows, power seats etc. you will probably need a higher output alternator. Also, having a 300 amp alternator on a low demand system will not overload the system. It will work fine. You will just be paying a whole lot more for amps you will not use. I guess I said all that to say this... Match the output of your alternator to the demand or load of your system. And as Steve has said, match or exceed your wire size to the output rating of your alternator.

|

|

By HT32BSX115 - 14 Years Ago

|

Howdy,

I used the Vintage Air A/C and alt brackets for my 292.

you could easily make them if you wanted to.

I also bought a rebuilt 100A 12si alternator from Autozone. I used a VW alt for a core. they didn't seem to care what I gave them for the core.

I also removed the single groove pulley from teh alt and replaced it with double groove one....

regards,

Rick

|