|

By joey - 14 Years Ago

|

|

Just replaced my Mallory with a used '57 TBird distributor. Seller said it was just rebuilt, it's straight, no excess play, clean. It reportedly has new condenser, rotor and points, which is all consistent with what I'm seeing. I set the point gap, and the dwell while cranking the engine is at 27. With #1 cylinder at TDC (compression stroke), the rotor is pointing directly at #1 sparkplug on the cap. The engine backfires violently and won't start. Car was running before the dizzy changeover. I have checked and rechecked all the plug wires for correct sequence and good connections. Nothing else (coil, carb, etc.) was changed. WTH? What should I check next?

|

|

By Ted - 14 Years Ago

|

|

I’ll suggest that you double check that you are indeed on #1 compression stroke and not #1 overlap. TDC on the damper comes up on both. Still sounds like you’re 180° off on the distributor. You might also check that the point gap is in the vicinity of 0.017”-0.019” at high point on the distributor lobe while you’ve got the cap off. I'll add that you can pull the passenger side valve cover off with the damper on TDC and both the #1 valves should have some play in them if you are on #1 compression. If the valves are both tight, then you're likely on #1 overlap (180° off). I'm assuming you are working on a Thunderbird which shouldn't present an issue as far as a slipped damper as far as timing readings or the TDC mark is concerned. On the non-Thunderbird dampers, a slipped damper will throw you a curve.

|

|

By joey - 14 Years Ago

|

|

OK, I'm gonna run back down and pull the valve cover and check they're both closed. It's gotta be something stupid like that. Thanks

|

|

By joey - 14 Years Ago

|

It was something stupid like that.  Fired right up. When am I gonna learn not to be in such a hurry. Fired right up. When am I gonna learn not to be in such a hurry.

|

|

By Pete 55Tbird - 14 Years Ago

|

|

Joey I think Ted is correct. The distributor is installed so it fires with the valves on that cylinder open. You can STATIC TIME an engine. Find the 0 on you timing mark on the dampner with the engine off. Take off the valve cover on the number one cylinder ( or really any cylinder) to confirm the two valves are closed and that piston is at the top of its stroke. Turn on the ignition and rotate the distributor until the points break and you see a spark. The rotor is now pointing at number one cylinder ( or any cylinder you want to fire now). Turn off the ignition, tighten the distributor hold down to just snug. Replace the spark plug leads in the right sequence, Number one spark lead MAY NOW HAVE CHANGED its location on the cap, in direction of rotation. The engine will start and using the new number one spark plug lead location time the engine with your timing light. You did replace that valve cover, right? Pete

|

|

By joey - 14 Years Ago

|

|

Thanks much gents, as always. Now I gotta set initial timing, then check centrifugal, and then vac advance. Got my timing light and analyzer... but it won't happen til later because now it's raining cats and dogs here.

|

|

By yblock55 - 14 Years Ago

|

|

The same problem was on my Y. I just solved the problem by turning the cap 180 degres.

|

|

By joey - 14 Years Ago

|

|

It now appears that I have sprung an oil leak from the bottom of the oil pump, which I took apart to get at the oil pump drive shaft. When I put it back together I noticed the only gasket was a very light O-ring, it looked OK so I re-used it. The NAPA guy came up empty on his computer with regard to the O-ring, but suggests that he could probably match one up, as their stock O-rings come in many sizes. But it occurs to me, mightn't the correct O-ring be flat sided on one side? Does anyone know? Also (and maybe more important) was there ever a gasket under the square-ish cover plate that is held on with four small bolts? There isn't one there now...should there be a paper gasket maybe? Seems odd to me to just have metal on metal and expect it to seal. If there is supposed to be a cover plate gasket, couldn't I make one?

|

|

By charliemccraney - 14 Years Ago

|

Is this the oil pump you have?

The plate at the lower right is sealed to the pump housing with an o ring that has a square profile. You can barely make out the groove in which this o-ring fits in the pump housing. The screw at the upper right is sealed with a gasket which looks to be paper.

A paper gasket seals the pump to the engine block. The oil pickup tube is sealed with a thick round rubber gasket.

|

|

By aussiebill - 14 Years Ago

|

charliemccraney (4/14/2011)

Is this the oil pump you have?  The plate at the lower right is sealed to the pump housing with an o ring that has a square profile. You can barely make out the groove in which this o-ring fits in the pump housing. The screw at the upper right is sealed with a gasket which looks to be paper. A paper gasket seals the pump to the engine block. The oil pickup tube is sealed with a thick round rubber gasket. Charlie, i have noticed that the o ring has been normal o ring section in the gasket sets lately and will work. As most folks have the cast pump and dont use the o ring for aluminum pumps, there should be one laying around in a gasket set somewhere?? i have a few.

|

|

By joey - 14 Years Ago

|

|

Yes, that's the pump I have, thanks Charley. I did find the O-ring from Tee Bird Products, cost of $1.25. Rather than try to match something up, I called them and ordered it. I've run into a couple of issues with the '57 distributor, but first I want to dig into it some more tomorrow. Right now I gotta get some sleep.  Thanks guys. Thanks guys.

|

|

By joey - 14 Years Ago

|

|

OK, a couple of concerns I want to run past you guys... 1) The distributor cap is NOS, Motorcraft, with the #1 plug hole demarcated on the surface, and has a cutout along the rim to allow for the fit of the vacuum advance module. But the cap isn't a good fit--it isn't snug to the distributor body. And if you apply a little manual torque to it, the engine starts to run rough. Anyone had any experiences like that? 2) With the vacuum advance disconnected and plugged, I set initial timing at idle (550 RPM) at 10 degrees BTDC as a starting point. With engine revved to 1500, the centrifugal advance shows 25 degrees (that is, the original 10 + 15 more). Then at 2000 rpm, it yields 33 total. I know I need to check it at higher rpms as well, but it's hard because I'm by myself right now. Anyway...are those numbers a bit high? (This engine has a higher lift cam and ported C heads, and I do want a good spark advance. But those readouts are before vac.) 3) When I connect the vacuum advance line, the engine quits immediately and burps back through the carb. I have now pulled the advance module off the dizzy and will take it apart. But why would it kill the engine entirely? The diaphram is supposedly brand new, and it does hold when I suck the air outward. Any words of wisdom are appreciated.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Sounds like you are connecting to "live" manifold vacuum at idle - and the combined 10° initial plus the vacuum - plus it probably speeds up(?) - all of that is making the engine "over-advance". If that is the case - Try plugging the vacuum line into a "ported vacuum" source - that port should only give a vacuum signal as the throttle blade leaves the idle position. When you rev the engine with mechanical advance alone - where does it stop advancing when the initial is 10°? Your orignal tests seemed to show the full advance was 33°-10° = 23°. Is that all of it or is there mopre if you go higher in rpm?

|

|

By charliemccraney - 14 Years Ago

|

The cap can rotate some when it is clamped down but there should be some resistance. Under normal operation, it should not turn on its own. So, if the cap just flops around when it's clamped down, there is a problem. If it stays put you should be good.

I think your timing is advancing faster than it should. You are getting about 1 degree of advance per 63rpm, that puts you at 39 degrees of mechanical advance at about 3000rpm (49 degrees total), assuming that the mechanical advance does not stop advancing before that point (it very likely does stop advancing before then). I think you need to slow the rate of advance so it's all in no sooner than 3000RPM and possibly limit it to about 24 - 28 mechanical with 12-14 of initial. From there you will be able to fine tune.

Not sure about the vac advance.

|

|

By joey - 14 Years Ago

|

|

Hi Steve, I connected the vac line to ported vacuum at the carb. It's a Demon carb and it has the little brass vacuum ports just above throttle plate level. That's what's confusing the crap out of me. Car won't start with this line connected. <When you rev the engine with mechanical advance alone - where does it stop advancing when the initial is 10 ?> My sense is that it's not finished mechanically-advancing when you exceed 2000 rpm, although that's as high as I got. I still need to compile more specifics, but it's difficult to do this alone. I need to rig up a temporary throttle arrangement. Edit: I did take apart the vacuum advance module. It's perfectly fine, holds it's vacuum...appears to be brand new as the seller indicated.

|

|

By joey - 14 Years Ago

|

|

Charlie: if further tests confirm that the mechanical advance is advancing too much, the way to address that is to try new springs, correct? Too much advance would indicate too large of a discrepancy of spring strength between the two?

|

|

By charliemccraney - 14 Years Ago

|

|

The springs will change the rate of advance. To change the amount of advance, I believe, will require that you either grind the slots to get more advance or braze or weld the slots to get less advance on that particular distributor. I'm more familiar with the Motorcraft distributors.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

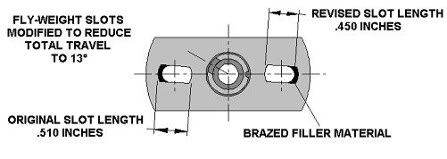

Joey - If you are using the ported vacuum port, it should have no vacuum at idle with the throttle blade very near closed. So attaching the line - or detaching it - at idle shouldn't have an effect on the engine speed. The Autolite distributor would have the "slotted" type of centrifugal travel stops in the upper rotor shaft (has the cam above the point plate). Upper LH in this picture.

We usually shorten the slot to limit the total advance added by the centrifugal mechanism - and as Charlie says, control the speed it comes in by changing the springs.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

This diagram shows the way I stop the travel at 13° - its then 26° at the crank. With 10° initial this makes a total of 36° - a good total value for a Y-block. The full slot shown on a standard upper rotor is good for about 20° - therefore 40° at the crank, which is way too much if you experiment with elevated initial values or really light springs. Could be previous owner used light springs and a very small (or TDC) initial.

|

|

By joey - 14 Years Ago

|

|

OK, I've solved one issue. Demons have 3 vacuum sources at the baseplate. One large, at the back, is direct, and I use that for PCV. Then there are two ports, side by side, along the baseplate on the passenger side. I ASSumed that since they're less than an inch apart and both brass fittings resemble each other that they were both ported, that is, above the butterflies. But they're coming from different sources. One is direct, while the other is ported. When I didn't require vacuum to the distributor, I had one capped off, and the other hooked to the vacuum pump. So now, can I hook the vacuum pump up to the direct port? My Ford shop manual doesn't specify.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

You are powering a vacuum pump with the small direct port, correct? and the ported vacuum would then go to the distributor vacuum pot. If you are using the ported vacuum source for the distributor, an initial value up near 14° would be appropriate for cammed up engine - but you would have to limit the slot travel so that you only got 22° (11° at the dizzy) to avoid going over 36° total mechanical. My Road Demon Jr. pulled so much air through the PCV that I had to restrict it - otherwise the idle ran up too high. There are smaller passage PCV's available to do the same job.

|

|

By joey - 14 Years Ago

|

|

GREENBIRD56 (4/15/2011)

You are powering a vacuum pump with the small direct port, correct? and the ported vacuum would then go to the distributor vacuum pot.Yes, that's all correct. GREENBIRD56 (4/15/2011)

If you are using the ported vacuum source for the distributor, an initial value up near 14° would be appropriate for cammed up engine - but you would have to limit the slot travel so that you only got 22° (11° at the dizzy) to avoid going over 36° total mechanical. My Road Demon Jr. pulled so much air through the PCV that I had to restrict it - otherwise the idle ran up too high. There are smaller passage PCV's available to do the same job. Yes, I have restricted mine a bit as well. Actually using one for a 3.3L engine.

|

|

By joey - 14 Years Ago

|

|

Update: The advance on this distributor at present stops advancing at 2900 or 3000 rpm, with a total of about 36 degrees. That is with the vacuum connected. I have to do more interval checks comparing numbers with the advance line connected/disconnected. But it appears at first look that the vacuum signal from the Demon isn't very strong at all. However I was again having trouble with the darned distributor cap. Just the normal vibration of the engine jiggles the cap enough to make the engine run rough. Grab the cap and hold it in a certain position, and everything smooths out. Because of this a road test isn't doable, so I have no idea if this distributor will be an improvement over the previous.

|

|

By Pete 55Tbird - 14 Years Ago

|

|

joey Why not just FORGET ABOUT the vacuum advance for now. For years lots of cars came without any vacuum advance and the world did not end. Harbor Freight, and most other places sell a dial-back timing lite that one person can operate. Get the mechanical advance set right and then go from there. Don`t try to multi-task on this one. Pete PS any NAPA or any parts store will have a distributor cap for a 57-74 ford V8. Try one

|

|

By joey - 14 Years Ago

|

Pete 55Tbird (4/15/2011)

joey Why not just FORGET ABOUT the vacuum advance for now. For years lots of cars came without any vacuum advance and the world did not end. Because vacuum advance, along with tach drive, is part of what I want. I already had a distributor without it. I know the world will not end.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

I believe the "trick" is to get the mechanical advance to work right - plenty of early advance, 36° limit, and all in by say 2800/3000 rpm. This is done with no vacuum advance at all - the distributor hose is pulled and plugged (got golf tees?). When your mechanical advance is capable - then you add sufficient vacuum advance to enhance the economy. In my case I've got it limited to about 7° maximum and thats all. The extended early advance prevents using too much more without spark knock. My outfit has a stocker cam - the heated up version you are running will take a different set-up I'm sure.....

|