|

By 56FairlaneAZ - 14 Years Ago

|

|

I have a 56 Ford Fairlane with a 292 Y-Block, Holley 600 carburetor and a Fordomatic automatic transmission. I’m having trouble getting it to idle in both Park and Drive. When I set the idle properly in Park or Neutral and then I shift it to Drive or Reverse the RPM’s drop off to ½ of what they were and it'll barely run. And when I move the idle up to get the car to run in Drive or Reverse and shift to Park or Neutral the idle goes up to double what it should be. I’ve had 2 different Holley carburetors (1 was a warranty replacement) and 2 different sets of ignitions components. Local transmission expert tells me it can’t be the Fordomatic. Any ideas?

|

|

By charliemccraney - 14 Years Ago

|

|

Is the 292 stock, otherwise? Does it have the stock distributor?

|

|

By oldcarmark - 14 Years Ago

|

|

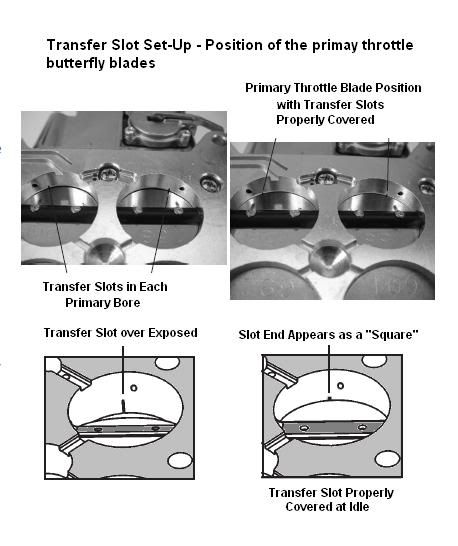

I had the same problem with a 390 Holley.First step is to take the carb off and turn it over(after emptying the gas in the float bowls).If you look at the throttle body in the area where the butterfly closes you will see a slot in the throttle body.This is a "transition slot" which allows fuel to enter as you leave idle such as starting away from stop position.With the butterfly closed you should only see a "square"below the throttle plate.If you have much more than that exposed too much fuel enters at idle and you will never get a satisfactory idle in drive.Back off the idle speed screw until you have just a square visible below the butterfly.Make a note to yourself how many turns of the speed screw ÄFTER the screw contacts the throttle lever to get that preferred position of the butterfly.Mine was about 3/4 turn.If you start adjusting the idle speed and lose that position while doing so you can start again without taking the carb off.When you reinstall and start it he idle speed should be about right with maybe a small adjustment.If you turn it too far you start to draw fuel from the transition slot which cannot be controlled by the mixture screws.Than you are back where you started.I know exactly the impulse to turn the speed up.If you cannot get a proper idle speed with the throttle plate in preferred position and mixture screws about 1-1 1/2/2 turns out from closed position you likely have a problem elsewhere like a vacuum leak possibly.Also check the float levels to be sure fuel is not dripping into throttle bore.If you have a stock motor like mine you should not need to try the following suggestion.The secondary plates also have a provision to open them a little at idle to allow more air in.If you have the carb off look at the base plate below the secondary throttle.Should be a threaded hole which would take a threaded screw which can be used to hold the plate open a little for air to enter.Sometimes with a hipo motor holes are drilled in the leading edge of the primary plates to allow more air to enter.Adjusting the secondaries does the same thing.Also bump your initial timing to a bout 10-12 BTDC if you have not already done so.Check the Holley website for more info on setting initial idle speed.They have illustrations also.Hope this helps.Been there before myself.

|

|

By 56FairlaneAZ - 14 Years Ago

|

|

Thanks I'll try this....Yes it's a stock 292 with what I think is the stock distributor (it has duel vacuum advance). And I bumped the timing up a little and it seemed to run a bit better!

|

|

By oldcarmark - 14 Years Ago

|

|

If you do a search using the search topic at the top of each page on 'transition slot" theres several previous discussions on this topic.The second or third one started by "Pops" has some illustrations about page #5 to clarify what I am trying to describe.If you are still using the stock distributor(which I think you are) a fairly inexpensice improvement is to purchase a later distributor for a 1964 F100 with 292.They can be purchased as a rebuilt unit through any auto parts supplier.You need a cap and rotor for the same unit as they are different than the stock cap.This gives a much more responsive timing advance based on engine load at low speed throgh the vacuum advance and at higher speeds using the centrifugal adavance.The existing distributor is vacuum only.Ford changed to the better dist. in 57.If you shop around for that dist they can be had between $50.00 -$80.00.Check around they are all from the same rebuilder.

|

|

By charliemccraney - 14 Years Ago

|

Well, it may not be causing your problem, but you need a distributor for a 57 or newer Y with that carburetor. For the time being, to eliminate the advance system as a cause, disconnect the vacuum lines and plug the ports so there are no vacuum leaks. This will eliminate the ignition advance from the system and ensure that you're only dealing with static timing at idle.

Oh, and do you know if the car functioned properly before the 600 was installed?

|

|

By oldcarmark - 14 Years Ago

|

|

Charlie is absolutely right.I was just sitting here thinking about your question and the light went on when I realized you chenged carbs without changing distributors.The original will only work with the original carb which has a special spark advance valve built into the carb.You wont get any advance at all using the old dist.If you use the application I mentioned 1964 F100 with 292(the last year in N.America the y-block was used) you can get prices calling around.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

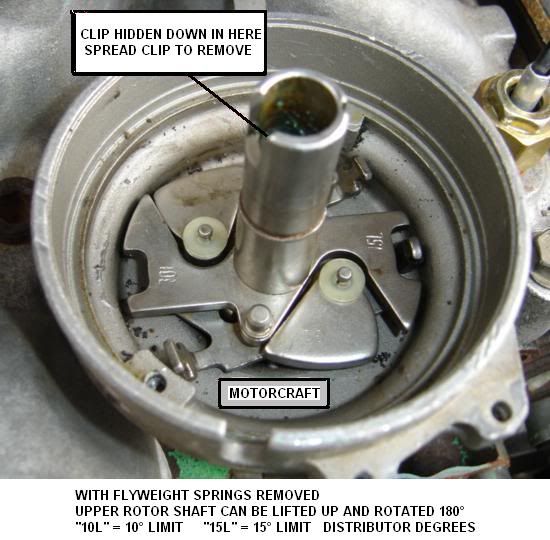

this photo shows the old style distributor - it has to have the old '56 carb vacuum ports in order to work. The two springs on top of the point plate are a quick indicator.

The later one will be like below:

|

|

By GREENBIRD56 - 14 Years Ago

|

|

This is the idle transfer slot that Mark is talking about. When this isn't set up right, Holley 4160 carbs will do nothing but fight you......

If it won't idle with the primary throttle positioned as shown above and the initial timing set at 10° before TDC - there is a small screw under the vacuum secondary operating lever to open the secondary blade a bit. Resist the urge to move the primary stop screw - no matter what. The one for the secondary is on the passenger side of the carb and screwed in from the bottom. Opening the secondary will add a bit of air to keep things going while you set the primary mixture screws for best idle speed (or highest vacuum).

In the old days - it was common practice to actually drill some extra holes in the primary throttle blade to get this extra idle air......don't. I usually put a longer screw up into the stop position and cut the head off to make it an "all-thread" - and then just turn it with needlenose pliers. Most intake manifolds and adapters have room for it to stick out on the down side. Don't get fooled by having a free flowing entry through the PVC system - it can run up the idle speed by pulling air in through the breather. Plug it or get an orfice in there to restrict it a bit.

|

|

By oldcarmark - 14 Years Ago

|

|

Hi Steve! 56FairlaneAZ did not mention a PCV system but you are right to mention it.Part of my problem ,after I took your advice and setup the carb as you and I have explained here,was the PCV valve was too big.I went from one for a 302 Ford to one for a 4 cylinder Fairmont/Zephyr.Fixed the lean idle.I remember working on mine trying to get it to idle in drive.I thought at one point i had a convertor problem because when it was put into drive it would almost die.Put it in neutral and it was fine as 56FairlaneAZ has mentioned.Once I got the throttle plate positioned properly I was on the way to getting it running like it should.If(when)56FairlaneAZ gets the distributor we can help him get that setup like I did with mine(with your guidance).For about $6.00 it can be made to work even better.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

56FairlaneAZ - As Charlie and Mark have said, you will be a lot happier with the later distributor - say '58-'64 - as the mechanical and vacuum advance systems are compatable with a lot of different (and more modern) carburetors. The dizzy you have is dependent on a "venturi vacuum" signal and the Holley 4160 doesn't provide porting for that signal. AutoZone in Tucson says Cardone P/N 30-2808 is a rebuilt for a '64 292 F-100 truck - $57.99 and $15.00 for the core = $72.99. A cap and rotor to suit is P/N F2160G = $20.00 more. At least a 100 bucks.......unless you know someone with a later part they can sell you for a decent price. Before you install it - it would be useful to take a look at the mechanical advance mechanism (you would have to remove the vacuum can and point plate temporarily) as the parts that are installed and how they are oriented will determine the total (distributor) advance the unit is set up for. Let us know what you've got - and we can give you some advice about that.

|

|

By oldcarmark - 14 Years Ago

|

|

That part# for the distributor seems to be the same wherever you end up buying it from.I guess they are the only ones still rebuilding those distributors.Same part# I purchased up here in Canada.

|

|

By 56FairlaneAZ - 14 Years Ago

|

|

A PCV system? It's a crankcase vent tube and a filter. The PCV systems didn't come out till the '60.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Many of us have retrofitted our outfits with PCV - the suction port is on my carb and probably on your Holley 600 as well. By plugging up (covering) the road draft port on the LH side of the block - and (in my case) using the road draft tube port on the back of the valley cover - the PCV valves can be fitted to the earlier motors. If you are not using the carb PCV port - and don't want to - just make sure its tightly capped at the carb. Using one has the advantage of helping control oil leaks by applying slight vacuum to the engine internals, and it helps keep water from condensing in the crankcase - and staying there.

|

|

By oldcarmark - 14 Years Ago

|

|

Easy to retrofit.Get a valley pan for a T-Bird which has an opening at the back for a road draft tube.T-Birds have clearance issues if the draft tube is at the side of the block like yours and mine.You just ned a grommet and PCV valve and a piece of gas resistant hose to plumb it into the existing port on the carb.Plug the hole in the side of the block and make sure the oil fill cap is not plugged up.You will lose the "gassy" smell in the garage when its parked.As well you dont have the smoke from the draft tube when you take off.

|

|

By 56FairlaneAZ - 14 Years Ago

|

|

Thanks everyone for the help. I'll start shopping for a new distributor. Got a couple of catalogs that cover those years.

|

|

By oldcarmark - 14 Years Ago

|

|

Just call a couple of your local parts places.You will also need a cap and rotor for 57-74 Ford V-8.All the same in those years.I think Autozone might be one of the less expensive sources for the distributor.One of the advantages of the later distributors is you can buy lighter advance springs for about $4.00 from Mr.Gasket and rework the advance curve.You can also add electronic ignition and do away with the points.

|

|

By charliemccraney - 14 Years Ago

|

|

Did you fix the idling problem yet?

|

|

By 56FairlaneAZ - 14 Years Ago

|

|

Not Fixed yet. this little thing called work got in my way! http://www.y-blocksforever.com/forums/Skins/Classic/Images/MessageIcons/Crazy.gif But will get to it soon. but did some research and Autozone is by far the cheapest. Thanks for the help!

|

|

By oldcarmark - 14 Years Ago

|

|

Prioritize! Call in sick for a couple of days!

|

|

By 56FairlaneAZ - 14 Years Ago

|

Called in sick this year for too many car shows....

Got my distributor yesterday from a 1960 Ford Fairlane 292 y-block. Looks just like the pictures you guys posted. Went to the local Autozone here in Chandler. Gave “the kid” behind the counter the part number and was informed it's not available and he made no attempt to contact the warehouse. Also got “not available” from the Autozone webpage. I’m not a big fan of Autozone, would rather go to the local Napa where the counter men have some gray hair and know old cars. Found the distributor on-line through the Cardone webpage and got the same price as Autozone from RockAuto (but had to pay shipping). I bought the distributor, cap and rotor. An ex-y-blocker recommended I go with the Ignitor Electronic Ignition (smoother then the points set-up) from So-Cal Speed Shop. The 4+ year old coil was putting out less than 1.5 ohms so I added the Flame Thrower II coil. I also wanted to get rid of the ugly ballast resistor.

So guys my next question before I put this stuff together is: Do I have to do anything to set this distributor up? Change springs? Adjustments? Would rather work on it outside the car as much as possible, it’s a pain in the…after it’s installed. Thanks

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Depending on the rebuilder - many of the later versions use the small block Ford distributor body (with a y-block compatable shaft). It has a "three lobed" shank running down from the distributor body to the clamping base.

This is a "Motorcraft" distributor and the advance mechanism down inside will look like this....

The older design "Autolite" base has concentric rings around the shank like this one and the advance mechanism will differ. It will have kidney shaped flyweights with bronze bushings at the pivots.

The upper rotor shaft - that carries the point cam for the Motorcraft set-up will have a choice of two internal advance stops. They will be stamped as shown in the photo above - this one has "10L" and "15L" markings. Others can be found as well and parts can be swapped around - I usually hunt for and use the "13L" versions and they are often paired with an "18L" stamping. The tab sticking up from the base (at right in the 15L slot) sets your choice of the advance "range" (usually found with a small piece of black plastic tubing forced over it). By removing the advance springs and a clip down in the well at the top - you can spin these upper rotor shafts 180° and choose the other range of travel. So this one shown has a choice of 10° - or 15° of distributor advance - which will be 20° or 30° at the crank timing marks. Total advance for one of these engines (that is pretty much stock) should be limited to something like 36° / 38° (with no vacuum advance). The initial advance you set at idle and distributor centrifugal advance is summed as the engine accelerates, so the rotor shaft shown could be used with 16°/18° initial and the "10L" slot - or 6°/8° with the "15L". If you want to use a different initial setting and have this pretty much figured out - you can "customize" a "10L" slot to be what you need with a rat-tail file. Just remember its easier to make them longer than shorter.... A slight increase in one of the settings can be had by simply removing the little piece of black tubing off the travel pin. The common Y street engines like a lot of initial spark advance - 10° is a good start - but the choice of initial turns out to be a decision based on use of "live" manifold vacuum advance or "ported" vacuum advance from a specific port on the carburetor. There are proponents of both and they both can work well. My outfit runs 10° initial and live manifold vacuum - I believe that makes it start a bit quicker - and several I know use 14° initial with ported. We all end up at nearly the same 36°/38° total mechanical advance. The ported vacuum comes from a hole just above the throttle plate of the carb - so when you open the throttle, it "turns on" vacuum to the distributor and it becomes virtually the same as live manifold vacuum below the throttle plates. So it is basically using the throttle as an on-off switch for vacuum advance at idle. Keep in mind that using low amounts of initial advance - and ported vacuum - can result in the engine running relatively retarded and heat up at long periods of idle. Springs for the centrifugal advance unit - get a set of Mr. Gasket 925D springs so you can play with the speed at which the full advance is in the engine. It will depend on engine compression - and what sort of go juice you get at the pump locally - to determine how fast you want the curve to operate. Generally 3000 rpm is a conservative, safe "all in" value - but the lower you can make it all come in without knocking, the more "bottom end" you will build into your power curve. Where you start is a judgement call - but getting it perfecto on the first try is hard to do. There is a real advantage to knowing someone with an old style SUN distributor machine that can dial this in on a bench. Fact is, that many have learned to "curve" their distributors right at home in the driveway - so it is a time honored automotive tradition. The vacuum pots come in two varieties - an older version seen below.....

and another newer set-up that may or may not have an internal adjustment screw.

The older version can be disassembled to adjust both the full travel - and the spring rate. There is a bakelite tube inside controlling the travel - and the spring and shims are self explanatory. We have made longer pieces of tubing out of carbon fiber arrow shafting - but it doesn't have to be exotic. The vacuum advvance is a street tuning thing - it adds advance at low engine load to gain fuel economy. High engine vacuum indicates light load - vacuum adds advance - low engine vacuum says the throttle is way open and reduces advance to the mechanical (no-knock) settings.

This will get you started - ask more questions!

|

|

By oldcarmark - 14 Years Ago

|

|

Just be careful when removing the little spring clip inside the advance assembly.They go a long way if it takes off removing it and hard to find.Dont ask how I know.

|

|

By 56FairlaneAZ - 14 Years Ago

|

|

Finely getting around to putting in my new distributor. Had to put brakes on the car first. Something about wanting it to stop after I get it running. Pulled the stock distributor out but couldn't get the new one in because it keeps getting hung up on the lower flange. I did notice on the old distributor that both the lower flanges that go in the block are polished (never seen this before). Do I need to have these flanges polished? Any idea how to get it in? Did I get the wrong distributor?

|

|

By oldcarmark - 14 Years Ago

|

|

I dont think its hung up on the flange.More likely the drive gear is not quite dropping into place.Bump the motor just a little and it should drop into place.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

What Mark is refering to is the fact that your new distributor - doesn't necessarily have the drive gear teeth indexed to the oil pump hex drive exactly like the old one. Bumping or rocking the engine a bit will turn the camshaft - without turning the oil pump shaft - which often lets the gear and distributor fall down into place. Don't go too far - or the distributor rotor wil be out of phase with the engine. Personally - I like to "arrange" the number one cylinder plug wire at a particular point on the cap - so I put the engine on No. 1 TDC before trying to remove the old distributor and fit the new distributor and place the rotor. Several long 1/4 extensions taped together and a small hex socket (also taped on) to fit the oil pump drive will let you reach down and rotate the shaft to an optimum point to drop everything in as desired.

|

|

By 56FairlaneAZ - 13 Years Ago

|

Got the new distributor in with a new cap, wires, plugs and electronic ignition, then I set the timing and adjusted the carb. No more run on and rough idle. WOW! This is the best this Ford has run in the 4+ years I've had it! Thanks to everyone for the technical help. txtPost_CommentEmoticon(' '); I may be calling again when I have other questions. Thanks again! '); I may be calling again when I have other questions. Thanks again!

|