|

By MarkMontereyBay - 12 Years Ago

|

|

I am currently distracted building a 445 FE stroker motor for my 65 Galaxie. Part of the build is upgrading the rocker assemblies. This includes end rocker stand supports and shaft spacers between the stands. The supports on the ends of each shaft add strength to the unsupported end of the shaft to prevent breakage often associated with high tension springs. The spacers with shims keep the rocker arm centered on the valve stem tip. The Y block rocker arm assembly design is the same as the FE but I haven't seen any aftermarket parts for the Y. Am I missing something?

|

|

By Ted - 12 Years Ago

|

|

Although the Y rocker arm shafts are smaller in diameter than the Fe shafts, the Y shafts are more rigid and subsequently stronger simply due to not having the holes through them to attach the rocker arm assemblies to the head. Because the Y uses a rocker arm support system that uses bolts on each side of the shaft for cylinder head attachment, the shafts are not weakened by having holes through them in which to attach the rocker assemblies to the head. On the FE, it’s those end rocker shaft attachment holes where much of the flex occurs and hence, it’s at those points where breakage occurs much of the time. . On the Y, using the iron stands from the truck 302/332 LYB engines instead of the stock aluminum stands further reduces any potential for flex that might be occurring in the rocker shaft area. But that seems to be overkill as the factory aluminum stands for the Y engines do appear to be satisfactory even in the most severe of performance applications. Still, the Ford engineers did think that there was enough of a flex issue on the LYB truck engines that they did use iron rather than aluminum. The 406 and 427 FE engines also used iron stands instead of aluminum stands at the rockers to reduce shaft flex but because of the 13/32” diameter holes in the FE shafts used for rocker retention, it’s not a complete fix. Because of this, rocker arm end supports for any performance FE seems to be standard fare.

|

|

By pegleg - 12 Years Ago

|

|

The iron stands would have been much cheaper to manufacture. The price for aluminum would have been around $.50 or more per pound then and iron < $.05. The machining costs would have been similar. That means the iron stands may well have been an economic decision rather than an engineering solution.

|

|

By MarkMontereyBay - 12 Years Ago

|

|

Regarding the spacers between the stands, I was at the Monterey Historic races at Laguna Seca Raceway a few years ago. There was a 56 Tbird (Doane Spencer?) racing team. I spoke with one of the guys working on the car in the pits and he mentioned they had made spacers for the rocker shafts. This was to keep the rocker arms aligned with the valve stem tips. Seems like the stock Y block springs could make them vulnerable to moving under race conditions. I realize they are needed particularly with roller rocker arms but valve guide wear could be an issue as well. Any thoughts?

|

|

By Ted - 12 Years Ago

|

|

MarkMontereyBay (10/22/2013)

.... they had made spacers for the rocker shafts. This was to keep the rocker arms aligned with the valve stem tips. Seems like the stock Y block springs could make them vulnerable to moving under race conditions. I realize they are needed particularly with roller rocker arms but valve guide wear could be an issue as well. Any thoughts?

In dynoing some of the higher horsepower Y’s, it’s been found that using the springs instead of solid spacers between the rockers has been worth some additional horsepower. It’s surmised that the springs actually stops some of the unwanted ‘free’ movement of the rockers when they are between valve actions which helps to stabilize the valve train in general. . I suspect this would also be the case for the FE’s in some instances but I’ve never had the opportunity to test both scenarios on the same FE engine. . If there’s a weak point in the roller rocker arms for the Y, it would be in the amount of offset for the pushrods and/or roller tips. Some manufacturers adds the offset to the roller tips while others do it solely at the adjuster. This offset is generally necessary to align the roller tip with the valve stem while centering the pushrod within the pushrod hole in the head. These offsets puts a side pressure on the rocker at the shaft and can potentially cause the roller tip to fail prematurely due to the roller tip being forced into not seating squarely on the valve tip. I’ll also add that if the clearance is too great between the shaft and the ‘offset’ rocker, then oiling is also uneven creating the potential for some premature wear in that area. This is just food for thought.

|

|

By MarkMontereyBay - 12 Years Ago

|

|

Thanks Ted. I have been wondering now why Ford made the changes in the rocker shaft for the FE. Making holes in the shaft for the mounting bolts doesn't seem to make sense when compared to the earlier Y block arrangement.

|

|

By bn - 12 Years Ago

|

Although engineers had much more autonomy in a corporate environment in those days, I agree that going to steel posts was probably an economic decision. For the same geometry and load, aluminum has three times the deflection as steel. However, based on intuition alone, it seems that most of the deflection in the post would occur in the upper "hoop" region between the two bolts, and that this deflection would be relatively small compared with the deflection in the shaft in the midway region between posts. Therefore, it seems that whether the posts are made of aluminum or steel - it would have minimal effect on the maximum deflection at a rocker arm.

I just happen to have my rocker arm assembly apart right now, and just for fun I weighed an aluminum post. It weighs 2 oz. Eight posts, then, would weigh 1 lb. Steel posts made to the same geometry would weigh 3 lb. So the total weight penalty by going to steel posts would be 2 lb per engine - not much.

|

|

By glrbird - 12 Years Ago

|

Mark

Which Spincer 56 did you see? Was it this one?

http://www.kirkfwhite.com/1st.html

|

|

By MarkMontereyBay - 12 Years Ago

|

|

No, actually it was a Chuck Daigh car, not the Spencer Tbird. Memory was a little foggy.

|

|

By DryLakesRacer - 12 Years Ago

|

Even tho this does not pertain directly to the Y or FE The GMC 6 I have raced for years has a similar design. I made my own roller rockers using Torrington bearings on the stock shaft and Isky pined rollers tips. The stands were also made for the additional lift and off set. There is a pin hole on the end front stand so the original shaft can not rotate but can be assembled in either direction but not upside down for the original oiling which was thru the original shaft fed thru a hole in the head and fitting from the main gallery.

Long story short the original shaft broke at the end stand right on the line the pin was to hold it from rotating. My first thought was to support the end but it would be a tough design due to the lack of space. I chose to make a new shaft. (wish I could remember the starting material). The shaft is approx 30" long and the original center hole was 1/2". I found a place to rifle drill it at 3/8" . Brought it to a centerless grinding shop to get the preliminary diameter, drilled all the oiling holes, had it heat treated, and then finished ground. All this under the grinding shop directions. I'm sure this one will never break and being a lot smarter this time made 2.

This may not be right for the Fords. but racing takes it's toll and everything always finding the next weakest part. Took a lot of driving around and finding some one to do each part of what needed done. Luckily So Cal hasn't closed everything.....Good Luck

|

|

By charliemccraney - 12 Years Ago

|

|

Ted (10/23/2013)

In dynoing some of the higher horsepower Y’s, it’s been found that using the springs instead of solid spacers between the rockers has been worth some additional horsepower. It’s surmised that the springs actually stops some of the unwanted ‘free’ movement of the rockers when they are between valve actions which helps to stabilize the valve train in general.

Perhaps a future dyno test can be preformed to find out if there is an ideal spring tension.

|

|

By slick56 - 12 Years Ago

|

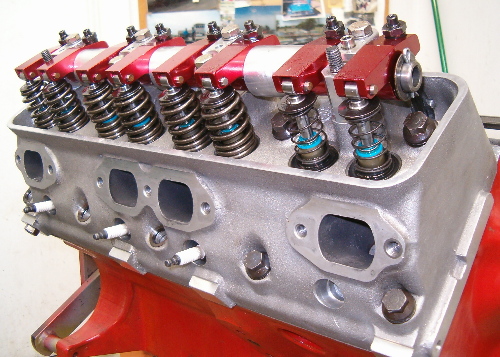

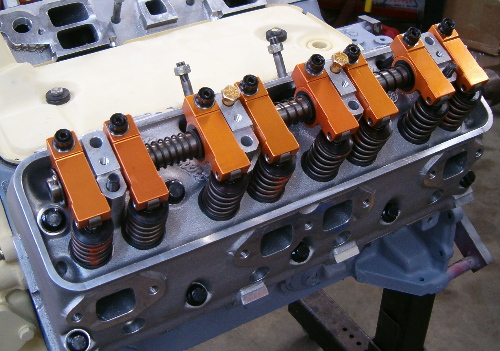

Pics of the spacers in (unposted) G heads from a 50's Nascar Y

.

|

|

By Ted - 12 Years Ago

|

|

Here’s a link to a past thread discussing iron versus aluminum on the rocker arm shafts. http://forums.y-blocksforever.com/FindPost4892.aspx I would have to guess that the aluminum stands are ultimately less expensive to produce than iron simply due to both the Y’s, FE’s, and LYB’s using aluminum for the bread and butter stuff. Performance applications and some of the trucks applications used iron.

|

|

By Ted - 12 Years Ago

|

|

And here’s a couple of pics of Y’s with roller rocker arms. One with solid bushings between the rockers and another using springs.

|