|

Author

|

Message

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Yesterday

Posts: 6.1K,

Visits: 442.8K

|

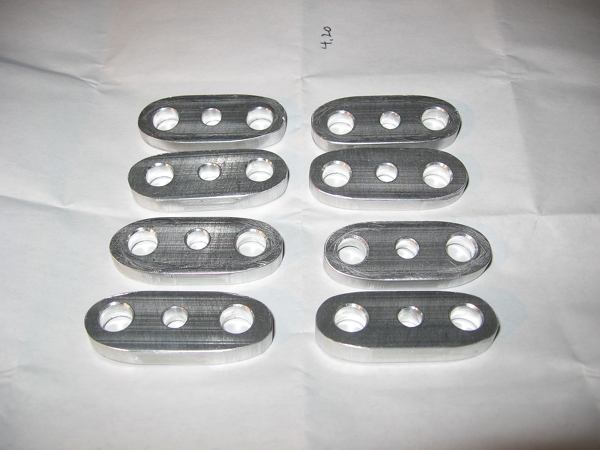

If the stands need to be higher, you need to shim them. Here is an example of shins i have made.

Lawrenceville, GA

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Yesterday

Posts: 6.1K,

Visits: 442.8K

|

DANIEL TINDER (11/20/2023)

“The High Side” (?). Does that that mean longer valve stems, or longer pushrods? (sorry if I’m a bit slow on the uptake). That means to err on the side of having the stand positioned slightly higher than ideal.

Lawrenceville, GA

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

Shimming stands?

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.7K,

Visits: 154.2K

|

“The High Side” (?). Does that that mean longer valve stems, or longer pushrods? (sorry if I’m a bit slow on the uptake).

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 10 hours ago

Posts: 7.5K,

Visits: 205.8K

|

To reiterate what Charlie mentions, changes to the head gasket thickness and any milling of the decks and/or heads will not have a bearing on the valve train rocker arm geometry on engines that use shaft mounted rockers. You can install 1” thick head gaskets and the valve train geometry will basically go unchanged. Granted the pushrod length will be affected but the actual geometry will not. Valve lift and the valve stem lengths, if changed, will affect the geometry though as the rocker arm pivot point in relation to the valve stem tip and rocker sweep is then being altered. I have found that biassing the rocker arm geometry to the high side is advantageous to low lift air flow but that will be at some expense to valve guide wear and/or longevity.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 927,

Visits: 190.0K

|

have you measured the latest head gaskets,in my case the thicker gaskets wher the same thickness as the trays.so with trays removed should be a time to check other changes (re surfacing heads and block).

also be careful with the head cap screws. the picture of ones being used(in 1 picture spells trouble

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Yesterday

Posts: 6.1K,

Visits: 442.8K

|

Joe-JDC (11/18/2023)

Typically milling the heads, decking the block ... will require adding shims, not milling the stands. I would expect those changes to require pushrod length be altered but not require any significant change to stand positioning. Since the Y uses shaft mounted rockers, the relation of the rocker to the valve stays the same no matter how much is removed from deck surfaces.

Lawrenceville, GA

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 927,

Visits: 190.0K

|

if you are using new style head gaskets(like I did) I did not use the metal spacers that wher suppose to direct oil.when I measured new style head gaskets the increased thickness and the thickness of the plates ,returned the rocker geometry back to stock

I would recommend 302 valve seales,but trim them so they are a bit shorter ,not as short as corect seals for y blocks

I have found supper lube going to all valve train as well as plenty of drainage back to pan both ends.

my own truck with 292 y never had to change rockers to valve stem adjustment as whole valve train gets proper lubrecation

have only rebuilt 4ys the last4 years but no complaints from any one

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

I have the oil tray baffles from my 55 heads. I will determine rocker arm geometry on 57 G heads with & without baffles to see which is better. Thanks, Daniel.

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.7K,

Visits: 154.2K

|

The early OEM Y-Block stand oil trays I have are around .043”, if that’s any help. If your target measurement is in the ballpark, finding a used set would likely simplify things (?).

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|