|

Author

|

Message

|

|

alanfreeman

|

|

|

Group: Forum Members

Last Active: 2 hours ago

Posts: 358,

Visits: 5.0K

|

Yes, that is the sending unit for the oil pressure gauge in the dash. The device attached to the sender is a condenser.

|

|

|

|

|

B-rad

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 323,

Visits: 1.5K

|

Is this the oil pressure sending unit? It seems to be just a tad too big to fit in the hole. And that's that thing attached to it for?

Brad

Sierra Vista Arizona

1954 Lincoln Capri

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.4K,

Visits: 205.3K

|

If it’s for a light, just check it with an ohm meter for continuity. If it’s for an oil pressure gauge, just check that there is some kind of ohm reading. Beyond that, just install it, hook up the wire, crank the engine, and see if you get a reading assuming it’s for a gauge.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

B-rad

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 323,

Visits: 1.5K

|

Is this the sending unit? Is there an easy way to test it while it's outta the car?   Brad

Brad

Sierra Vista Arizona

1954 Lincoln Capri

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.4K,

Visits: 205.3K

|

On the Ford Y, you will find the sending unit for the oil pressure light typically in that particular hole from the factory. I suspect the same was for the Lincoln Y or LYB engines. If you are getting your oil pressure reading from a different oil galley hole in the block, then a simple ¼” NPT plug in that particular hole will fix you up. Otherwise, hook up your oil light sending unit or an oil pressure gauge in that hole.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

B-rad

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 323,

Visits: 1.5K

|

I must've had a brain fart.  Found out that I had somehow put a bigger size socket on the extension so I was just spinning on top of the oil shaft. Put the correct size socket on and started spinning the oil pump. Soon after, I saw oil coming from a hole next to the oil filter. I'm sharing a picture of a long threaded rod i put in to stop the leak. The manual doesn't show what piece belongs there. Help please.

Brad

Sierra Vista Arizona

1954 Lincoln Capri

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 4 hours ago

Posts: 1.7K,

Visits: 305.5K

|

" There’s no mess or spillage when installing the filter when it’s empty. I do prefer priming by hand with a speed handle rather than a drill as if there is problem with the oil pump meshing smoothly, you will feel it with the speed handle but not if you have a drill motor turning the pump."

... hmmpf ...

I never though of the pump binding.

APPRECIATED!, and this my LEARNED FACTOID of THE DAY.

Always something to learn here.

____________________________

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.4K,

Visits: 205.3K

|

KULTULZ (10/7/2024)

...Interesting. Why a dry filter and not an electric drill (will be my newly learned FACTOID of THE DAY).There’s no mess or spillage when installing the filter when it’s empty. I do prefer priming by hand with a speed handle rather than a drill as if there is problem with the oil pump meshing smoothly, you will feel it with the speed handle but not if you have a drill motor turning the pump. A case in point is a BBC engine that was being primed by hand prior to being installed on the dyno and it had an obvious tight spot when rotating the pump. Upon removing the oil pump, its housing had been heat warped when the customer brazed his oil pickup to the pump. That would not have been found if using a drill motor to turn the pump.B-rad (10/7/2024)

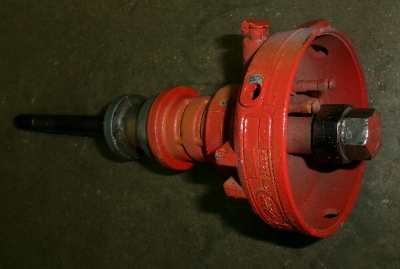

I see that the oil pump shaft is not centered in the hole in the block. That's why I'm not sure the socket is turning the shaft, it might be spinning on top of the shaft. Is there a trick to keep the shaft centered while putting the socket in the hole? Plus, it'll help putting the dizzy back in.Without a distributor lower shaft in the distributor pilot hole, it’s normal for the oil drive shaft to be lying to one side of the hole. Between the point or chamfer on the top of the oil pump drive shaft and the corresponding counter bore in the bottom of the distributor shaft, the two parts manage to align once the six sides of both the shaft and the distributor hole are aligned. For priming the oil system before an engines’ first start, I’ll use an old distributor that has the lower gear removed and a bolt welded to the top. With this, I can use a speed handle with the appropriate socket to turn the oil pump CCW for prelubing purposes. As mentioned earlier, it takes approximately 20 seconds to fill an empty oil filter and get a pressure reading on a gauge. Another 20-30 seconds will typically have oil at the rocker arms. Here's a picture of a distributor modified for oil priming purposes.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

paul2748

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 3.6K,

Visits: 497.6K

|

I use a 1/4 drive deep socket on an extension with speed wrench (3/8 with an 1/4-3/8 drive adapter) to make sure the socket connects with the oil pump shaft/drive. An ordinary length socket may not reach the oil pump drive.. Usually, the socket will just go over the drive - never had a problem with centering (except when putting in the distributor). B-rad (10/7/2024)

I see that the oil pump shaft is not centered in the hole in the block. That's why I'm not sure the socket is turning the shaft, it might be spinning on top of the shaft. Is there a trick to keep the shaft centered while putting the socket in the hole? Plus it'll help putting the dizzy back in.

54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

Forever Ford

Midland Park, NJ

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 4 hours ago

Posts: 1.7K,

Visits: 305.5K

|

Ted wrote - I prelube the engines using a speed handle and starting with an empty filter it takes ~20 seconds to get pressure at the oil galleys. It then takes roughly another 20-30 seconds to get a flow up to both rocker arm assemblies.

Interesting. Why a dry filter and not an electric drill (will be my newly learned FACTOID of THE DAY).

Regarding the oil pressure gauge, use the oil pressure sender port. This is a LYB.

____________________________

|

|

|

|