|

Group: Forum Members

Last Active: Yesterday

Posts: 19,

Visits: 117

|

Does anyone have a bellhousing and dowel position or original ford engineering drawing. I am about to make an adaptor to a v6 gearbox to fit into my car. If no one has I will post my measurements once found here.

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.8K

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 19,

Visits: 117

|

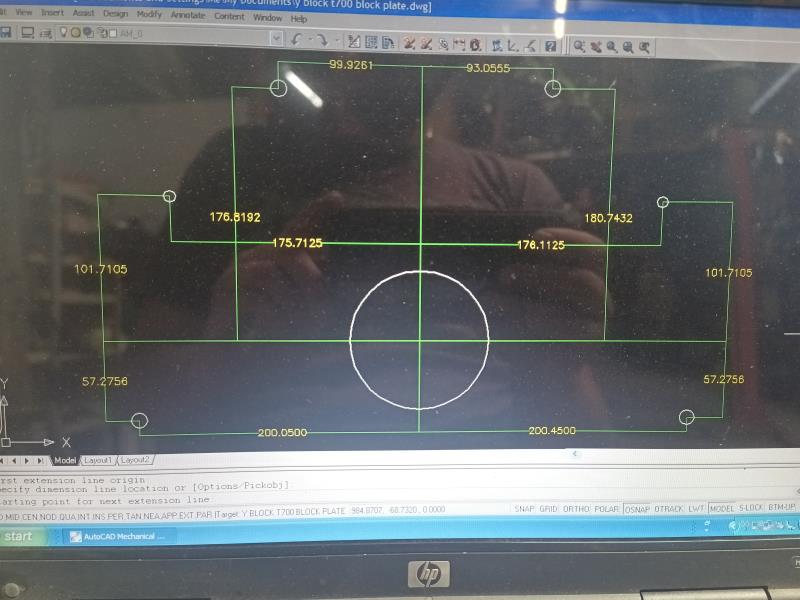

This is what I came up with I tried making holes equally spaced off the crankshaft centreline but had to adjust slightly to work with 4 of the easy to access y blocks I have here. These measurements are metric in mm (sorry US people) and places the crankshaft centre within 0.1mm on all of my engines. I checked using a plate I laser cut with a tight crank hole.

|