|

By Dan - 15 Years Ago

|

|

I am tired of telling you guys we are gonna get this built and then nothing happens, as such, the y-block for our T is moving to the head of the line! Yesterday the kids pulled the engine from the car and this morning gave it a good bath. This afternoon cam bearings and freeze plugs go in.... Before we put the cam bearings in, anything special I need to watch our for? The first one is different from the rest, right? It is wider and the rest are all the same?? Line up the oil holes and the third one has to line up with the holes on the side??? Thanks!

|

|

By Dan - 15 Years Ago

|

|

freeze plugs are in.... cam bearings are in and the oil feed holes line up, both in the bottom of the bearing and the side of the middle bearing... first cam bearing is sunk in .0012, right in the middle of the .005-.0020 specs for cam thrust washer clearance... was going to install the lifters and cam but when we opened our box of lifters they had a pretty heavy coat of cosmoline on them so we will let them soak until tomorrow... have a couple pics also I will post up ASAP...

|

|

By Dan - 15 Years Ago

|

|

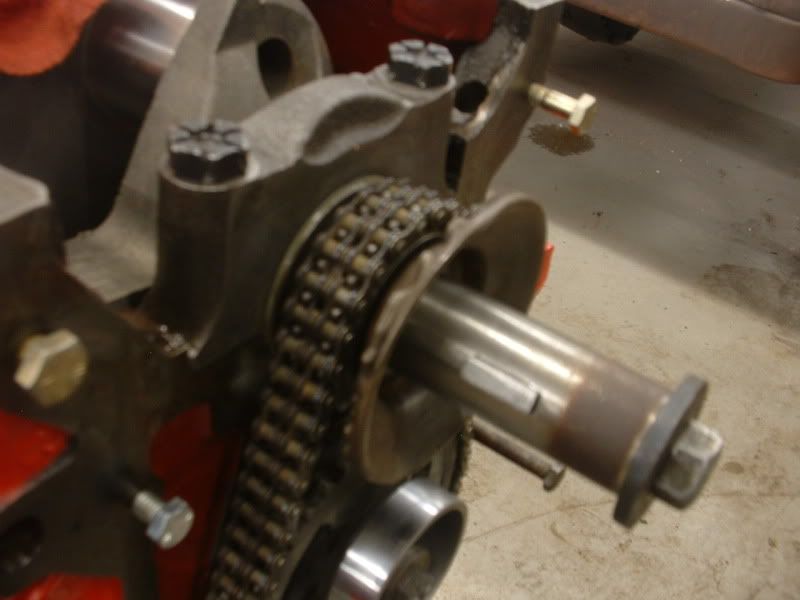

here is the engine coming out...

here are the students installing cam bearings and freeze plugs...

you can see him checking the alignments of the oil holes...

|

|

By ecode ragtop - 15 Years Ago

|

|

I WISH I HAD THAT MUCH HELP!!!!

|

|

By Dan - 15 Years Ago

|

|

So we hit our first bump in the road. Installing the crank and our thrust bearing does not fit. It fits in the saddle on the block but it is too narrow to fit the cap??? They are Federal Mogul 2002 CP, everything else fit like it should. Is the cap for the thrust bearing different than the rest??? Wrong bearings???? thanks-

|

|

By Hoosier Hurricane - 15 Years Ago

|

|

Dan: The center main cap is spotfaced on both front and back for the thrust bearing. Has someone mixed up the caps?

|

|

By Dan - 15 Years Ago

|

|

probably - I cant find any numbers on them anywhere and when we got the engine it was in pieces - I know the proper thing would be an align bore but not in the cards right now...we'll take a closer at everything...thanks-

|

|

By MoonShadow - 15 Years Ago

|

|

How about a picture of the offending bearing in the block? Chuck in NH

|

|

By mctim64 - 15 Years Ago

|

|

Look at the caps, the thrust is obviously different. You can't miss it. If they have been mixed up it is possible the others aren't in the right place so try each one and torque them one at a time to make sure the crank turns freely. There should be NO tight spots.

|

|

By Dan - 15 Years Ago

|

|

Found the cap, it was in the wrong spot... Good lesson for me, building an engine with a "committee" is a little different to manage, that and I got in a hurry....

|

|

By MoonShadow - 15 Years Ago

|

|

I'm probably preading to the choir but when I tear an engine down I always put the main caps back on the block to keep them in the right order and on the right main. The caps settle in and like to be matched back where they came from. Unless you are line boring. You never know how long a block will set after teardown so this practice helps keep them right. Just a minor teaching point! Glad it worked out! Chuck in NH

|

|

By charliemccraney - 15 Years Ago

|

|

I'll mark'em with a punch before removing them. Number punches if they're handy or a number of dots corresponding with the number of the main cap.

|

|

By Dan - 15 Years Ago

|

|

Crank, cam, timing chain in...waiting now to find a new thrust bearing as my Ebay score turned out to be the wrong bearings (.010 under, I need standard) I will have to post a pic of the oil slinger, looks weird to me but this is my first yblock so...

|

|

By Dan - 15 Years Ago

|

|

Question of the day.... our oil slinger has a keyway but it doesnt register on anything on the crank shaft, do we not have the crank gear installed far enough? Doesnt look like it can go any farther, but????

|

|

By charliemccraney - 15 Years Ago

|

|

It is held in place by the harmonic damper. I think the key way is in place so it'll fit over that 1st key.

|

|

By joey - 15 Years Ago

|

|

Like those pics! Keep 'em coming.

|

|

By MoonShadow - 15 Years Ago

|

|

If thats the crank you plan to run I'm sure you plan clean off the rust on the end. Just thought I'd mention it. Quick way to a seal leak. Chuck in NH

|

|

By Dan - 15 Years Ago

|

|

Next bump in the road... kids install the #1 and #5 pistons, go to torque the rod bolts, we used 50lbs-ft. per the James Eikman book. Took the fasteners to 30 first then came back to go to 50. One rod bolt broke and on the other rod it feels like the nut has stripped on the bolt. This is a brand new Napa torque wrench, I assume it is accurate?? Whats happening? Would hate to install all new rod bolts, I know alot of people do but alot of engines seem to go together fine with the old ones???

|

|

By aussiebill - 15 Years Ago

|

Dan (3/24/2010)

Next bump in the road... kids install the #1 and #5 pistons, go to torque the rod bolts, we used 50lbs-ft. per the James Eikman book. Took the fasteners to 30 first then came back to go to 50. One rod bolt broke and on the other rod it feels like the nut has stripped on the bolt. This is a brand new Napa torque wrench, I assume it is accurate?? Whats happening? Would hate to install all new rod bolts, I know alot of people do but alot of engines seem to go together fine with the old ones??? Dan, there different personal preferences for torqueing bolts etc, personally i would go 20,35.45 max, rotating crank slightly on each setting to check if bearing hasnt bitten on crank, which will show any clearance problems that may occur. I believe torque setting is 45 lb and i think you may consider replacing the rod bolts. i would recheck wrench stting. this is only a suggestion as there are other views just as satisfactory. regards bill.

|

|

By DANIEL TINDER - 15 Years Ago

|

|

charliemccraney (3/18/2010)

It is held in place by the harmonic damper. I think the key way is in place so it'll fit over that 1st key.

You could likely peek through the timing cover/fuel pump opening to insure the damper is holding the slinger tight.

|