|

Author

|

Message

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

I have finally got the rods, I tried to think them for balance, I made a tool to help it, but something does not work well because every time I try to weigh the same part gives me a different measure, any suggestions?

|

|

|

|

|

MplsMike

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 204,

Visits: 92.3K

|

Can you place something wide across the scale, like a board or a tray, and then set the rod on that?

MplsMike

'56 Parklane

Minneapolis, MN

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.8K

|

|

|

|

|

|

Lord Gaga

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 464,

Visits: 183.3K

|

Friction of the wrist pin.

"FREE SAMPLE"

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

I have made modifications, but with the same result, the measurements are always different, I think I'm going to stop balancing the rods, is this operation necessary?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.8K

|

capelo (3/7/2020)

I have made modifications, but with the same result, the measurements are always different, I think I'm going to stop balancing the rods, is this operation necessary?That's a 'Yes' on balancing the rods.

This may now be coming down to the resolution of the scale that you are using. You don't say how much variation you are getting in the readings. If the scale is reading in hundredths of a gram, then the hundredths resolution is going to be too fine depending upon the environment and fixtures being used. As long as the scale is consistent to a half a gram, you will be okay. Any air currents in the room will also play havoc with getting consistent readings. If you don’t have rollers as the contact points for the connecting rods on both ends, there will be enough friction or drag at those points to also prevent you from getting consistent readings. I have seen home-made rod measuring units that used paper clips as the contact points that worked satisfactorily.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

I have done dry assembly of the rods with the pistons to measure the free space with the platform, then milling for a zero platform, these are the measurements, I would like your opinion on how much to mill.

N°1- 0,044"

N°2- 0,043"

N°3- 0,044"

N°4- 0,052"

N°5- 0,045"

N°6- 0,0425"

N°7- 0,040"

N°8- 0,046"

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (3/8/2020)

capelo (3/7/2020)

I have made modifications, but with the same result, the measurements are always different, I think I'm going to stop balancing the rods, is this operation necessary?That's a 'Yes' on balancing the rods.

This may now be coming down to the resolution of the scale that you are using. You don't say how much variation you are getting in the readings. If the scale is reading in hundredths of a gram, then the hundredths resolution is going to be too fine depending upon the environment and fixtures being used. As long as the scale is consistent to a half a gram, you will be okay. Any air currents in the room will also play havoc with getting consistent readings. If you don’t have rollers as the contact points for the connecting rods on both ends, there will be enough friction or drag at those points to also prevent you from getting consistent readings. I have seen home-made rod measuring units that used paper clips as the contact points that worked satisfactorily. The accuracy of the scale is 0.1 gram. The variation in measurements can reach 5 grams. I think that the problem is the support on both sides, it must have too much friction and it does not get to focus since as it is set on a point it does not move from there and I do not know how to solve that, it comments on paper clip, but no I get to see that option, some image of some homemade gadget would be fine. The total weights if they are constant but separately never coincide is very frustrating. Rod 1 - 678,2gr 2- 679,2gr 3- 682,4gr 4- 682,6gr 5- 683gr 6- 684,1gr 7- 682,7gr 8- 681,2gr

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.8K

|

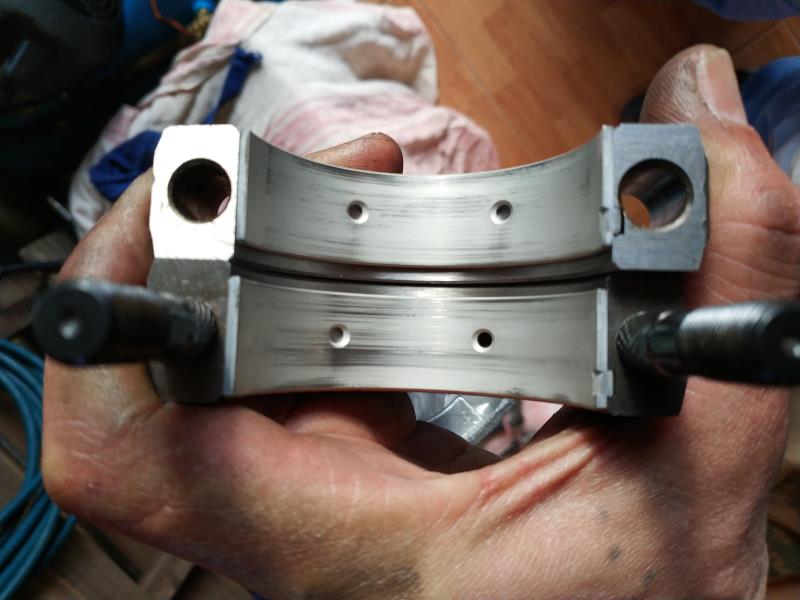

capelo (3/8/2020)

After the measurements and once disassembled everything I found these marks, is it normal or worrisome?  The wear marks on the bearings do look to be caused by dry assembling the parts without oil. That would be the result of metal to metal contact. Always use some form of oil or lubricant during any assembly of parts. Be sure all the parts are meticulously cleaned when the engine goes together. What you have right now will be okay if adequately lubed before reassembling.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|