|

Author

|

Message

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 3 hours ago

Posts: 6.1K,

Visits: 442.9K

|

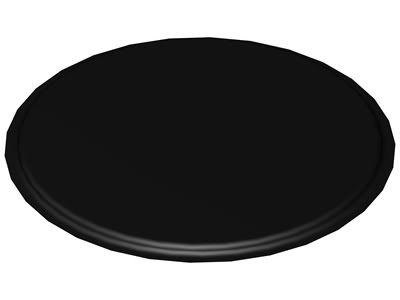

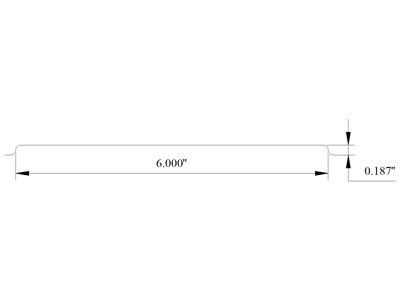

I'm looking for something like this. Or something from which I can acquire this.  with dimensions close to this. If it's too small to read, it is 6.000" and .187"  Needs to be steel, close to 20 gauge. Can anyone think of something like this?

Lawrenceville, GA

|

|

|

|

|

Barry L

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 217,

Visits: 6.7K

|

Charlie If I get a chance at work tomorrow,I'll see if I can make that on our rubber press.How exact do the dimensions have to be and how wide a flange around the perimeter(overall diameter) ? How soon do you need it and what does it do? Barry

|

|

|

|

|

pcmenten

|

|

|

Group: Forum Members

Last Active: 8 Years Ago

Posts: 375,

Visits: 1.1K

|

That looks like the lid to a pot.

Best regards,

Paul Menten

Meridian, Idaho

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 3 hours ago

Posts: 6.1K,

Visits: 442.9K

|

Thanks Barry, Let me get some more precise measurements and I'll let you know. It's a piece I'll use to modify my instrument panel for the new gauges.

Lawrenceville, GA

|

|

|

|

|

LON

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 523,

Visits: 3.7K

|

Charlie , Do you have anyone near you who does laser cutting ??? I needed some odd shaped pieces made to mount a Jag XJ6 front end into a 58 F100.I made them in cardboard,then had them made in 1/4 inch steel .It would have taken me 2 days to make them ,and they never would have been as neat as being laser cut .Six brackets for $60 .I thought it was great value . Lon

yblocksdownunder

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 3 hours ago

Posts: 6.1K,

Visits: 442.9K

|

I'm sure someone around here does laser cutting. I'm not sure that I can get what I'm looking for from a laser cut piece. Plus it sounds a little expensive for what I'm trying to do. Barry, I checked the status on my gauge today and learned it is 4 - 6 weeks out. I want to wait until I have it in hand so I can figure exactly what I need if I am to have someone make the piece for me. I'll let you know as soon as I know. I'll scour a salvage yard or two in the mean time to see if I can find anything useful.

Lawrenceville, GA

|

|

|

|

|

Barry L

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 217,

Visits: 6.7K

|

Charlie Something like this?  Just a quick pressing...mild steel .034...trim to fit...free plus shipping, this one's about 1/4" deep. Once you firm up dimensions , let me know if you want it refined . Barry L

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 3 hours ago

Posts: 6.1K,

Visits: 442.9K

|

Cool! Something like that is exactly what I'm looking for! I can't wait until I Figure out the dimensions. What does a rubber press look like, anyway?

Lawrenceville, GA

|

|

|

|

|

Barry L

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 217,

Visits: 6.7K

|

I'll take some pics tomorrow of the machine and the process (600 tons of power) in a fairly small piece of equipment. Barry

|

|

|

|

|

Barry L

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 217,

Visits: 6.7K

|

Rubber press info;   rubber is contained by outer steel edge,then cylinders compress the rubber over whatever form block is placed inside...great for stretching sheet metal the test piece was done in two hits...first over the square with the 6" hole,then with the 6" disc in the partilly formed depression to help refine the shape....the orange urethane block was placed over the disc for a little more omph

|

|

|

|