Why not just get the engine to TDC and verify where the dist. is set?

Really, it's not that mysterious. If it's off, just pull it out and re-install.

When you have to rotate the distributor that far to compensate for even one tooth off things like vacuum advance cans start getting in the way etc.

So you are better off getting it right.

When I used to run a conventional distributor, I would pull the distributor just to change or set points- it's really much easier that way.

As you drop the distributor down in there, the rotor will rotate as the gears mesh, then it will usually stop because it can't engage the oil pump drive.

Then just bump the starter and it will drop down the rest of the way.

So as you are dropping it down, the rotor will be rotating towards the position you want but be about 15 or 20 degrees shy of the final position when it stops.

After you bump the starter to drop it down the rest of the way, just rotate the crank back to TDC to verify.

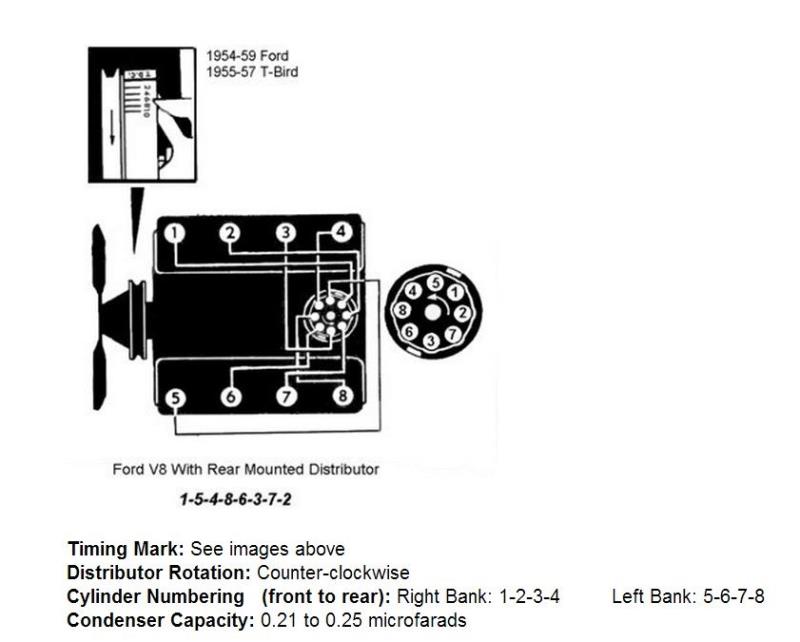

Here is a picture of the distributor with # 1 in the correct position and the firing order which may need verifying too.

But Ray- check it first before removing the distributor. You may not need to!