|

Author

|

Message

|

|

NathanxStewart

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 48,

Visits: 2.7K

|

Kahuna (8/2/2018)

My 32 is setup as Miker mentioned with the fill on the top tank offset. It works great. I also have an overflow tank that works well. I run a 12 # cap Sounds good, I think I just gotta do some refiguring!

|

|

|

|

|

NathanxStewart

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 48,

Visits: 2.7K

|

miker (8/2/2018)

I guess what I’d do is put in the inline cap and eliminate the tank for now. It’s the easiest way to find out I’d the cooling system works. You can run a hose to the catch can, verify it’s got enough volume, and make sure the vehicle cools. That way you've got a baseline that “works” for minimal cost and effort. Then you can do what you like, and if it doesn’t “work” take another look at the design. Like Roger points out, simple is probably the best. Okay, sounds good! I’m going to test out that inline cap and go from there. Thank you!

|

|

|

|

|

Kahuna

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 471,

Visits: 2.4K

|

My 32 is setup as Miker mentioned with the fill on the top tank offset. It works great.

I also have an overflow tank that works well. I run a 12 # cap

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.9K,

Visits: 194.9K

|

I guess what I’d do is put in the inline cap and eliminate the tank for now. It’s the easiest way to find out I’d the cooling system works. You can run a hose to the catch can, verify it’s got enough volume, and make sure the vehicle cools. That way you've got a baseline that “works” for minimal cost and effort. Then you can do what you like, and if it doesn’t “work” take another look at the design.

Like Roger points out, simple is probably the best.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

NathanxStewart

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 48,

Visits: 2.7K

|

miker (8/1/2018)

My 32 has a “filler neck” like your talking about adding, but it’s got enough radiator to manage the expansion with a small overflow/return bottle. It’s mounted low, like most vehicles. While I agree the system isn’t set up to allow proper fill/expansion, it might also be your lacking volume or cooling capacity. I understand your not afraid of fabricating something, but I’d stick on the filler neck up high and just connect it with hose. Then I’d live with the ugly until I knew the problem was solved. If it isn’t, there’s more work to do. It will also let you jury rig a catch can in and get some idea of the expansion volume you need to keep the system full. I don’t know if this is helpful, but years ago I had a fairly new Volvo that used a pressurized overflow tank. The radiator had a sealed cap, just like earlier models had a pressure cap. The overflow tube connected to a tank mounted alongside the radiator and it had the pressure cap. Kind of clear plastic, it was marked minimum and maximum. The only time you unsealed the radiator was to drain to flush it, otherwise it was done thru the tank cap. I wasn’t real hot about a plastic tank being pressurized, but like most things Volvo in the 60’s it just worked. It took a while to bleed the air out if you started from empty, but part of that was the heater was higher than the radiator. Once you know you do have cooling capacity, you can fab a pretty solution, maybe still using your expansion tank. This picture is of a couple year newer Volvo, and has a pressure release it looks like on the radiator. Mine didn’t, just a sealed cap. But it was what I could steal off the net.  I do have an overflow down low and it does suck the coolant back in (sometimes). I’m thinking I might do that inline filler neck deal and by pass the filling reservoir I currently have to test it and see what happens. I’m just wondering if I could get away with welding an elbow up high with a filler neck and pressure cap and still use the filling reservoir tank where it’s at with a cap on it? Or would it just continue to spew out there because when the rpms go up the flow increases and since its passing through the tank/ hose would it push past the cap cause the flow is increasing and causing pressure?

|

|

|

|

|

NathanxStewart

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 48,

Visits: 2.7K

|

56Roger (8/1/2018)

Of course you can absolutely do whatever you wish. But it seems to me whatever it all is you are going to add is not going to change anything except to increase complexity. The coolant level will be the same or higher than it was. If the little tank and pressure cap remain the same as they were then the pressure in the system will still cause a leak there same as before. Makes no sense to add parts to bleed off pressure. It's there for a reason. I live in central Florida. 2 Y-blocks, both run 7lb. caps. Never any problems on either of them. Not at all sure you need the 16lb. cap you are running. If you want less pressure try a lower pressure cap. But the cap simply needs to be at the highest point of the system with enough space somewhere to account for expansion of the coolant. As I said at first, that system is designed to leak . That's why it hasn't been fixed with everything you have tried so far. The actual problem has not gotten any attention. No real point trying to re-invent something that's been figured out for a very long time. The cooling systems for engines started out real simple and they worked well. Especially on hot rods. Expansion tank on top, low or no pressure cap. As time went on they became more and more complex for all kinds of reasons. Not many (there are a few) of which have anything to do with hot rods. But if that's what you're after go for it. Early 60s Y-block Fords used expansion tanks. And the FE's too. Find one or find good pictures of some and copy what they did if you can with the placement of your parts. Don't think you be able to. Or want to. And who needs it anyway. That's all I got. Okay so what if I weld an elbow at the highest point on the top tank of the radiator with a neck and a pressure cap, do you think I’d get away with leaving my current fill point (the fill tank) and just cap it off? Or would the tank still cause problems? As in not let the coolant flow smoothly through the system

|

|

|

|

|

56Roger

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 29,

Visits: 25.9K

|

miker (8/1/2018)

My 32 has a “filler neck” like your talking about adding, but it’s got enough radiator to manage the expansion with a small overflow/return bottle. It’s mounted low, like most vehicles. While I agree the system isn’t set up to allow proper fill/expansion, it might also be your lacking volume or cooling capacity. I understand your not afraid of fabricating something, but I’d stick on the filler neck up high and just connect it with hose. Then I’d live with the ugly until I knew the problem was solved. If it isn’t, there’s more work to do. It will also let you jury rig a catch can in and get some idea of the expansion volume you need to keep the system full. I don’t know if this is helpful, but years ago I had a fairly new Volvo that used a pressurized overflow tank. The radiator had a sealed cap, just like earlier models had a pressure cap. The overflow tube connected to a tank mounted alongside the radiator and it had the pressure cap. Kind of clear plastic, it was marked minimum and maximum. The only time you unsealed the radiator was to drain to flush it, otherwise it was done thru the tank cap. I wasn’t real hot about a plastic tank being pressurized, but like most things Volvo in the 60’s it just worked. It took a while to bleed the air out if you started from empty, but part of that was the heater was higher than the radiator. Once you know you do have cooling capacity, you can fab a pretty solution, maybe still using your expansion tank. This picture is of a couple year newer Volvo, and has a pressure release it looks like on the radiator. Mine didn’t, just a sealed cap. But it was what I could steal off the net.  I have an 84 MB with a similar setup. The radiator itself has NO cap. The plastic expansion tank is mounted on the fender well with the pressure cap higher than everything else. In fact nothing in the engine compartment is higher than that cap. The Volvo shows pretty much the same thing. Marked with "min" and "max". The "min" mark is about 1/3 the way up the tank, to be checked when the coolant is cool only. At cool temps the level in the tank is the same as in the radiator (water seeks it's own level) and the rest of the tank is for expansion. The placement of the hoses from the expansion tank is important. There is a 3/8" or so (10mm) hose from the top of the upper tank of the radiator to an upper point on the expansion tank that is just below the level of the pressure cap. The Volvo shows this as well. Not exactly what I would call a "pressure release" but in a sense that is what it is doing. Not getting released out of the system but released to a different part of the system to equalize it. Likely no coolant is ever "flowing" through this hose. A bit may cross over now and then, say in spirited driving. Call it a balance tube. The hose from bottom of the expansion tank is about 3/4" (19mm) and it goes to the bottom of the radiator, right next to the lower hose in this case. And then there is the usual little hose from just above the seal of the pressure cap in case something bad happens. Sprays it around the lower engine compartment instead of the upper part. Sort of. The small upper hose allows the pressure (whatever it is) to equalize between the radiator and the expansion tank. The larger lower hose provides an easy path for the coolant to rise and fall with expansion as necessary. The larger hose mitigates any problems draining the radiator as well. There is no "flow" through the expansion tank during operation, only in and out cycling with engine temps. I think all systems provide for these functions, one way or another. On an old system it all happens inside the radiator with no more parts necessary. Modern systems have varied means but they all do the same thing. Keep the cap higher than the level of the coolant at all times. Allow for expansion and a way to suck the coolant back in as it cools down after operation. All without leaks anywhere. If any shop built cooling system can do these things by whatever means it should work fine. Hundreds of millions of cars running around to prove it. Edit: My understanding is the expansion tanks came about at least partly (mostly?) because of the designer's desires to get the hood lines lower. Get that tall radiator out of there. Along the same reasons for the slant six.

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.9K,

Visits: 194.9K

|

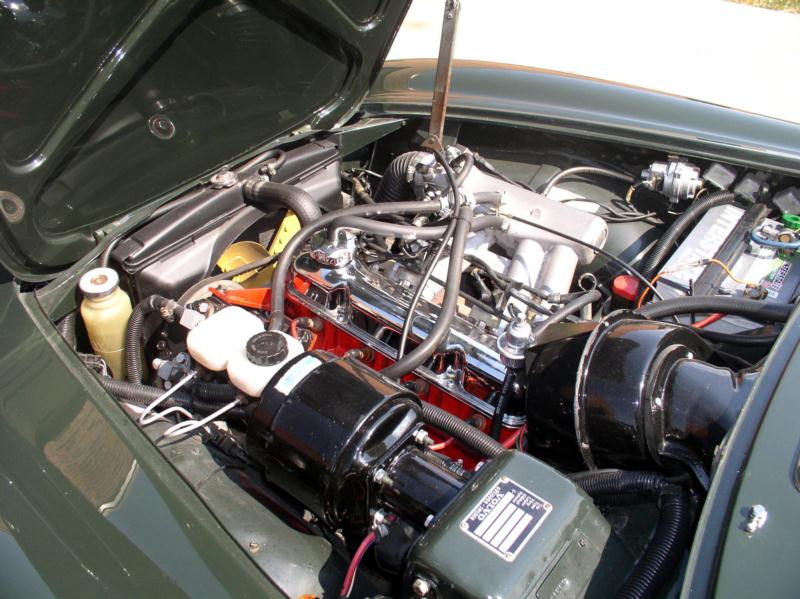

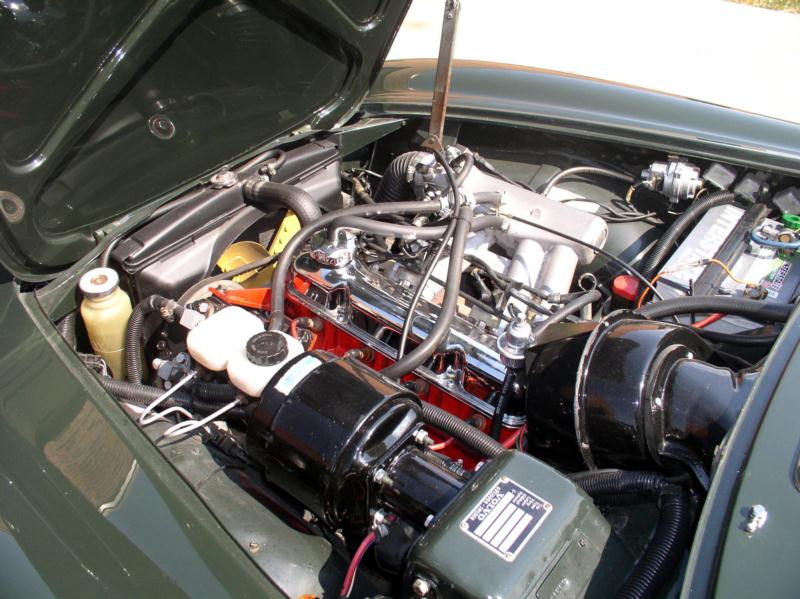

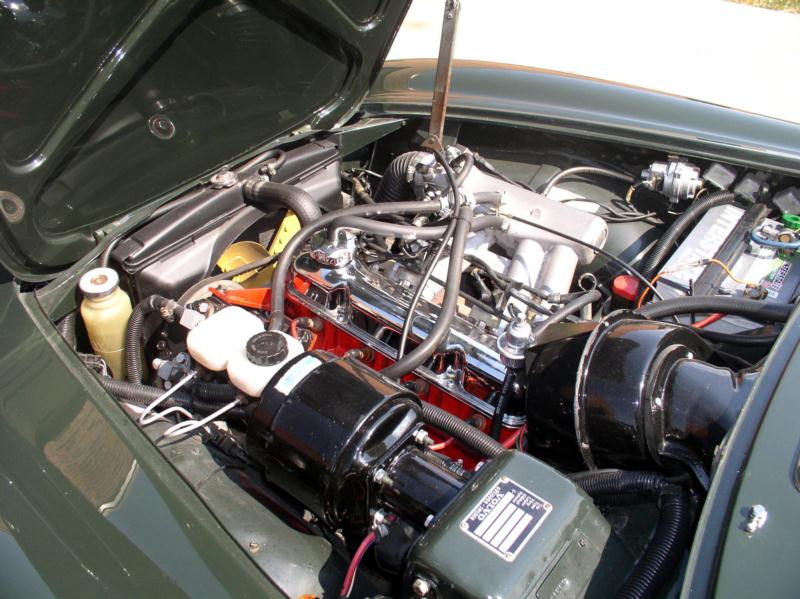

My 32 has a “filler neck” like your talking about adding, but it’s got enough radiator to manage the expansion with a small overflow/return bottle. It’s mounted low, like most vehicles. While I agree the system isn’t set up to allow proper fill/expansion, it might also be your lacking volume or cooling capacity. I understand your not afraid of fabricating something, but I’d stick on the filler neck up high and just connect it with hose. Then I’d live with the ugly until I knew the problem was solved. If it isn’t, there’s more work to do. It will also let you jury rig a catch can in and get some idea of the expansion volume you need to keep the system full. I don’t know if this is helpful, but years ago I had a fairly new Volvo that used a pressurized overflow tank. The radiator had a sealed cap, just like earlier models had a pressure cap. The overflow tube connected to a tank mounted alongside the radiator and it had the pressure cap. Kind of clear plastic, it was marked minimum and maximum. The only time you unsealed the radiator was to drain to flush it, otherwise it was done thru the tank cap. I wasn’t real hot about a plastic tank being pressurized, but like most things Volvo in the 60’s it just worked. It took a while to bleed the air out if you started from empty, but part of that was the heater was higher than the radiator. Once you know you do have cooling capacity, you can fab a pretty solution, maybe still using your expansion tank. This picture is of a couple year newer Volvo, and has a pressure release it looks like on the radiator. Mine didn’t, just a sealed cap. But it was what I could steal off the net.  miker

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

56Roger

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 29,

Visits: 25.9K

|

Of course you can absolutely do whatever you wish.

But it seems to me whatever it all is you are going to add is not going to change anything except to increase complexity. The coolant level will be the same or higher than it was. If the little tank and pressure cap remain the same as they were then the pressure in the system will still cause a leak there same as before.

Makes no sense to add parts to bleed off pressure. It's there for a reason. I live in central Florida. 2 Y-blocks, both run 7lb. caps. Never any problems on either of them. Not at all sure you need the 16lb. cap you are running. If you want less pressure try a lower pressure cap.

But the cap simply needs to be at the highest point of the system with enough space somewhere to account for expansion of the coolant. As I said at first, that system is designed to leak . That's why it hasn't been fixed with everything you have tried so far. The actual problem has not gotten any attention.

No real point trying to re-invent something that's been figured out for a very long time. The cooling systems for engines started out real simple and they worked well. Especially on hot rods. Expansion tank on top, low or no pressure cap. As time went on they became more and more complex for all kinds of reasons. Not many (there are a few) of which have anything to do with hot rods. But if that's what you're after go for it.

Early 60s Y-block Fords used expansion tanks. And the FE's too. Find one or find good pictures of some and copy what they did if you can with the placement of your parts. Don't think you be able to. Or want to. And who needs it anyway.

That's all I got.

|

|

|

|

|

NathanxStewart

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 48,

Visits: 2.7K

|

I believe my next step is to get a piece of aluminum tubing that's a 90 degree elbow, put a hole at the highest point of the top tank and weld the elbow there. There for I can fill it there then just put a plug on it. But still use my current fill neck with a pressure cap. Just won't fill there.

After what everyone has suggested to me it seems like that'll help get any steam pocket out of the system and it can flow.

Sound like it will work to you guys?

Thanks again for all of the suggestions!

|

|

|

|