|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

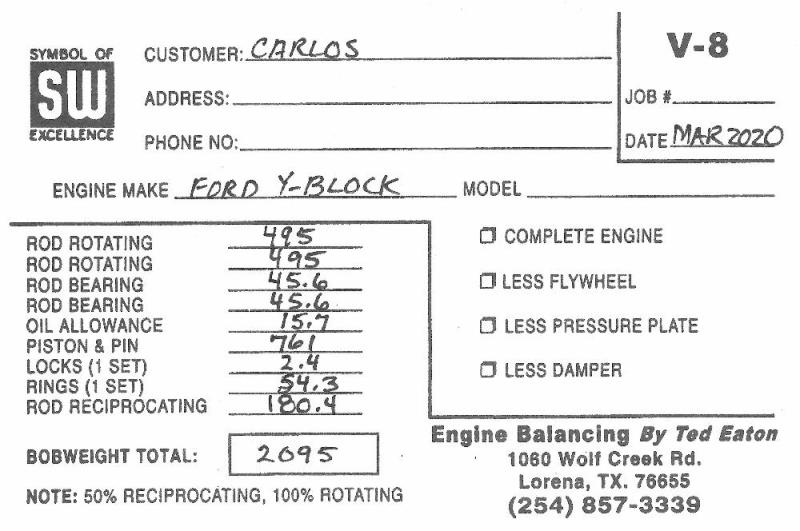

well, I have already solved two problems, I have already been able to adjust all the pistons with a difference of 0.002 "and the platforms will be milled to find a zero (1,2,3,4-0,042") and (5,6,7, 8-0.043 "). On the connecting rods I have already been able to think them and balance all the weights with a margin of 0.5gr. Now I am going to send to balance the crankshaft, damper and flywheel, I have to calculate the weight Bob but I do not know exactly how is done, I have the following:

Piston plus pin -761 gr

Rings - 54,3vgr

Pin clik-2,4 gr

connecting rod small side- 180,4 gr

connecting rod large side-495 gr

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

Do you have the rod bearing weight?

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (3/15/2020)

Do you have the rod bearing weight? 45.6gr

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (3/16/2020)

The formula for calculating the balancing bobweight for a 90° V8 is typically 50% of the reciprocating weight and 100% of the rotating weight and then adding 2 grams of oil for each rod piston assembly. The oil number is controversial and I find that the 4 grams that is added for each bobweight (2 cylinders) is on the low side. For the Ford Y, I’ll use a minimum of 15 grams for the oil number for each bobweight. Total bobweight values are rounded up to the nearest whole gram value. For your combination, the calculated bobweight value looks like this.

thank you very much Ted, you never fail, 🍻👍

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

I'm having trouble finding who performs the dynamic balancing of the crankshaft, they do it only static, around here it's not a common thing since there are usually no V-motors that go through the machine. I have found a company that does dynamic balancing but when talking to them they do not use the Bob counterweight to balance, I think it is because of what was said before they do not do it in V engines. To perform a dynamic balance of my crankshaft in that way would be worth to something, or would it be useless work and expense?

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (3/20/2020)

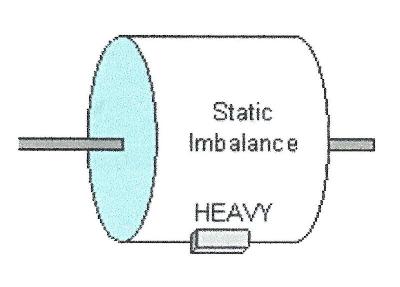

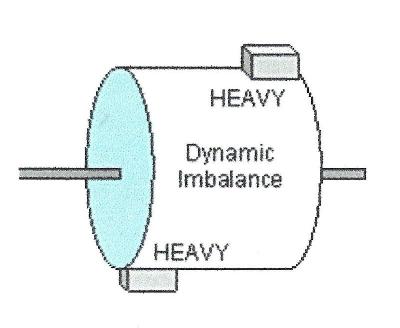

Dynamic balancing is required on crankshafts. As the weights of the pistons and rods are changed or altered from the original values, the crankshaft must be rebalanced accordingly. While something as thin as a flywheel can get away with being static balanced, anything with any length such as a crankshaft requires dynamic balancing to insure each end of the crankshaft is appropriately balanced. Here are a couple of pictures showing the fundamentals of static versus dynamic balancing.

Here’s an article that was published in The Y-Block Magazine going into more detail. http://www.eatonbalancing.com/2007/11/21/engine-balancing-part-1/ Here’s an article that was published in The Y-Block Magazine going into more detail. http://www.eatonbalancing.com/2007/11/21/engine-balancing-part-1/ In my case I only have two options, or only static or dynamic balance but without placing the counterweights, which in that case I do not know if it is of any use. I had already read your articles and I know the importance of doing things well, thanks for sharing, but if a dynamic balance is not done, will this affect any type of circulation or only in high revs?

|

|

Group: Forum Members

Last Active: Last Year

Posts: 464,

Visits: 183.3K

|

Capelo, Just curious. Where are you located?

"FREE SAMPLE"

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 279,

Visits: 4.5K

|

Lord Gaga (3/20/2020)

Capelo, Just curious. Where are you located? I am in Spain

|