|

Author

|

Message

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 513,

Visits: 153.3K

|

Pertronix Ignitor will handle a pretty wide range of voltages. It's nothing more than a Hall effect sensor/switch. What it can't handle though, is excessive current (heat).

This is why the total primary circuit resistance figure is important. I wouldn't say Pertronix info is contradictory, the problem is there are many different combinations that can be put together. People very often order the wrong parts. An ultra low 0.2 ohm resistance ignition coil paired with the original recipe series I ignitor, well, it isn't going to last very long.

You can figure it out for yourself using Ohm's Law.

|

|

|

|

|

Saltshaker

|

|

|

Group: Forum Members

Last Active: 2 Months Ago

Posts: 21,

Visits: 1.1K

|

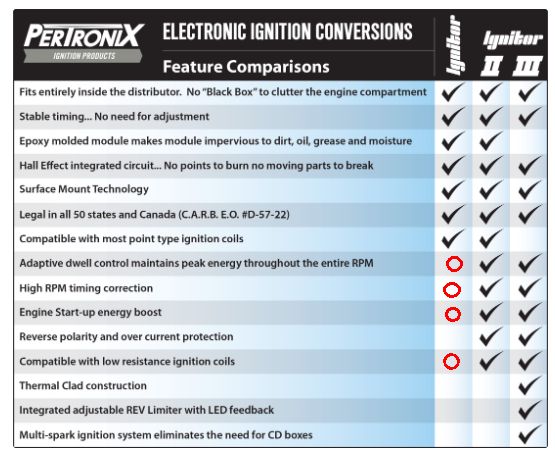

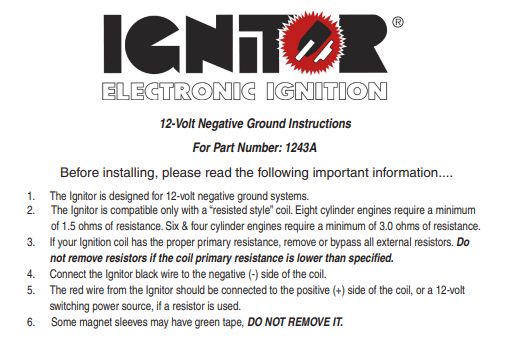

Here's a bit of conflicting info from Pertronix that came from a current document on their website. This is not the first time I have seen them doing this. Some may be caused by dated material. I think some of the uncertainty in whether to use or not use a ballast resistor comes from Pertronix selling three different versions of Ignitors, a standard Ignitor (formerly called called Ignitor I), an Ignitor II, and a Ignitor III. Pic 1. Note that one of the main differences is that Ignitor II and III have adaptive dwell. That's really not a true statement. It should say have adaptive dwell TIME. Dwell angle can't be changed, dwell time is constantly changing with engine RPM. At idle the dwell time is long and can overheat the coil. Speed it up and dwell time is extremely short, to the point of not fully saturating the coil with current. That, and point bounce will never allow a points system to be used for racing without doing major modifications such as dual points and increased point spring tension. So, go fast and the ignition misfires because of short dwell time. Go slow, and burn up the coil because of long dwell time. Pertronix II and III have adaptive dwell time control so using a ballast with them is not needed. Pertronix I does not, so there must be a balance between the ballast resistor and primary winding in the coil. Here is Pertronix's instructions on that. Pic 2

I think you have the right take on it. An 8 cylinder can use a 1.5 ohm or a 3.0 ohm coil without a ballast, but if it's not a performance issue use the 1.5  with a ballast. with a ballast.

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

I think where Pertronix may be going with the 1.5 ohm minimum requirement is to protect the Pertronix device itself. After all, it too has it's current handling limitations. They are concerned with warranty issues. It's up to the end user to figure out what electrical values any particular coil needs. Yes, the 1.5 ohm coil marketed by Pertronix IS designed for the increased current and I personally have run that coil with no resistor and no issues for several years as other folks have done. If you try coils of unknown pedigree or specifications you may be asking for roadside trouble. Yes, any coil designed to be used with a resistor must be used accordantly. It almost always states on such coil: USE WITH EXTERNAL RESISTOR or something like that. So called 12V coils are 7 V coils because during cranking, the working voltage at the coil is still 7 +- volts when the resistor is bypassed by the starter solenoid so will produce full spark energy during the cranking event. I have, years ago, mocked up an entire ignition system to run on my distributor machine. Long interesting story shortened, by simply placing a jumper across the resistor, the sound and intensity increase of the spark was very obvious along with the fragrance of ozone. IMO, the best and safest setup is the 1.5 ohm Pertronis coil. That combo will produce energy far beyond any stock system with resistor and that has to be good for better cleaner combustion/fuel burn and all that.

64F100 57FAIRLANE500

|

|

|

|

|

peeeot

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 357,

Visits: 25.5K

|

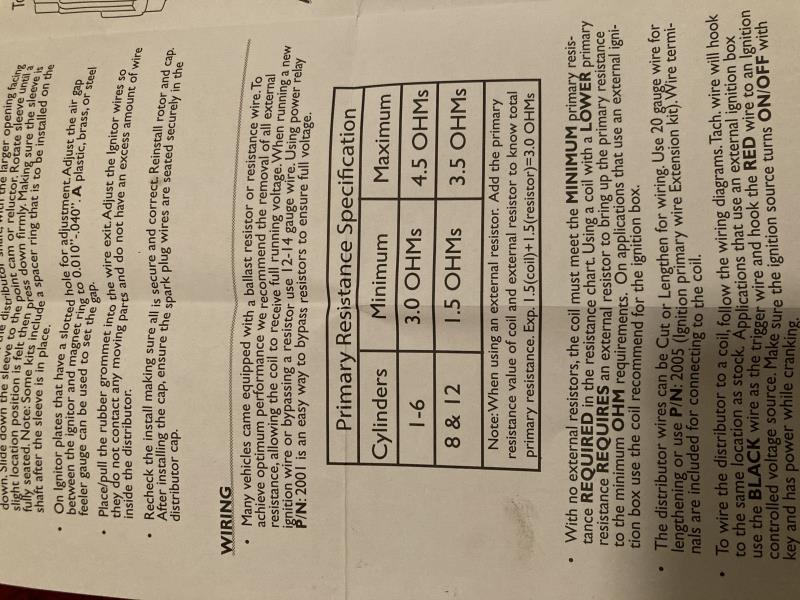

Interesting. So, reading between the lines, you (both) are implying that the 1.5 ohm coil marketed by Pertronix is designed for the doubled current afforded by losing the resistor (total primary resistance of 1.5 instead of 3.0) so both it and the Ignitor switching module can handle it. Meanwhile, stock point-type coils are not designed for the extra current and would consequently live shortened lives, even though the ignitor itself would still be fine. Am I understanding you correctly? Where my confusion comes in is that the guidance from the instructions seems to go against that. Here is a photo of the instructions included with my 1281 kit.  As I read it, any coil or coil+resistor combo is fine provided that, for a V8, total primary resistance is 1.5-3.5 ohms and 12V is supplied to the ignitor module itself. Seems like using an internally-resisted coil, or a stock coil+resistor, would be “safer” but may reduce spark energy as mentioned above. For my street-driven car I’m not sure that I’d ever know the difference. I just figured if Pertronix recommends not using a resistor, I’d go with their recommendation. DryLakes, you posted while I was writing. It does seem like a matter of preference as you say, and like you I am just looking for reduced maintenance and reliable operation. I hope I can be one to say “ten years with no trouble!”

1954 Crestline Victoria 312 4-bbl, 3-speed overdrive

|

|

|

|

|

DryLakesRacer

|

|

|

Group: Forum Members

Last Active: 4 days ago

Posts: 1.7K,

Visits: 340.1K

|

Manufacturers needed to lower the voltage and added the resister because 12-14.5 volts burned up the points! The first car I added 12 volts and a V8 to was a 53 GM car and I burned up the points in 5 miles. Because of coil heat I bought the Pertronix coil and kept the stock ballast resister after a call to them. They said either way and like others have said not quite as high of a spark under driving circumstances but with the bypass a hotter starting spark just like the stock points set up. It’s choice like they said.

To me the advantage was no more condenser failures or point maintenance.

56 Vic, B'Ville 200 MPH Club Member, So Cal.

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 729,

Visits: 112.0K

|

FORD DEARBORN

You provide great technical info which is right on, I try to keep mine short and simple because I hate typing.

I always wondered why they never built a true 12V coil, maybe they has so many 6V coils in stock it was cheaper to just add a resistor LOL

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

57RancheroJim you pulled the trigger before I did. Well said in a few words.............

64F100 57FAIRLANE500

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

I've always thought of the Pertronix as a switching device like a set of points. The yellow-top coil is not truly a 12V coil. It operates at 6-7 volts accomplished by the additional 1.5 ohm resistor. When cranking, the resistor is bypassed for ease of starting only. Eliminating the 6V drop across the resistor would put full battery voltage across the coil when the points close and since the Pertronix is taking the place of the points, it should have the same effect on the circuit. This would also double the current and that will produce a very rapid rise time for greater saturation producing a much hotter spark - the beauty of Pertronix. The current of the yellow top coil is kept in check by the 1.5 ohm resistor. With out is, the current doubles. So, the 1.5 ohm coil would work if the resistor is kept in the circuit, IMO. If the Pertronix has a current limiting feature at some threshold then I'm not aware of it and besides, that would defeat the purpose of developing a modern hot ignition. The current is not straight forward because there are other things going on like dwell time and inductance. Never the less, the book states 4.3 amps with the engine stopped and 2.5 amps idling in the primary circuit. Without the resistor, this current would effectively double but not for long. Maybe a Pertronix instruction sheet would address this?

64F100 57FAIRLANE500

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 729,

Visits: 112.0K

|

I have one engine running a stock mustard top coil with a pertronix. You need the external ballast resister to cut the voltage down from 12V to about 8V as the factory designed it or the coil will overheat and burn out. The Pertronix is best run on 12V and thats why they recommend splicing the hot ( RED ) wire for the unit into the 12V line before the resistor.

|

|

|

|

|

peeeot

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 357,

Visits: 25.5K

|

Ford Dearborn, are you saying that a conventional (not pertronix-brand) coil, such as the stock Ford yellow-top, will not work with the pertronix ignitor module unless the system has a resistor? I have the understanding that any coil having 1.5-3.5 ohms primary resistance will work with the pertronix.

1954 Crestline Victoria 312 4-bbl, 3-speed overdrive

|

|

|

|