|

Author

|

Message

|

|

miker

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.9K,

Visits: 194.9K

|

Steve's post with the wiring diagram has it right. Full voltage to the coil on starting, and reduced (resistor) for running to stop the arcing from burning the points. In the old days, when you couldn't afford a dual point Mallory, you ran a switch to bypass the resistor for racing on the street. Points and files were cheap and time was free. In the late '60's I had an 11.5 to 1 312, and after I bought the white pump Chevron, money for parts got a little tight.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

pcmenten

|

|

|

Group: Forum Members

Last Active: 8 Years Ago

Posts: 375,

Visits: 1.1K

|

Congratulation. There's nothing like the feeling of seeing your newly overhauled engine start right up and purr.

It is absolutely vital that you put ZDDP in your crankcase while the engine is fresh. I'd recommend getting the Red STP Oil Treatment for four cylinder engines. One of those motorcycle sunzagunz did analysis on various sources of ZDDP and found that the Red STP is the highest concentration. GM EOS might still have ZDDP. STP Blue bottle also has ZDDP.

Good luck.

Best regards,

Paul Menten

Meridian, Idaho

|

|

|

|

|

uncleaud

|

|

|

Group: Forum Members

Last Active: 13 Years Ago

Posts: 62,

Visits: 863

|

Well today was a great day. The 312 is a running breathing thing again. I got the electric buggs worked out by using the jumper around the resistor. The new out of the box Holley had a bad o ring on the needle and seat, had to solve that this morning, but after everything quit leaking I gave it a couple squirts with the accelerator pump and it fired right up. Have to say, I don't think I've ever started a new build that wanted to run like this did. It fired on all 8 and just started to purr. No spits no sputters. I let it run three or four times at high idle til it was up to temperature. It would set right at 165 which is what the thermostat dictated. I set the lifters cold like Walt Knuckles (is that the right name,? don't look right now that I've typed it) discribes, tight to zero then back them up a quarter turn and they seem to be good. How do you tell when the solid lifters get out as they seem to tick all the time anyway. I guessing it starts to sound more like a washing machine than a sewing machine  Like a said it was a good day. Thanks to all on this board that have been a help. Now to get busy on the body.

|

|

|

|

|

uncleaud

|

|

|

Group: Forum Members

Last Active: 13 Years Ago

Posts: 62,

Visits: 863

|

Its a new 12v starter. The transmission has been changed to new style overdrive so the starter was updated too. I'll jumper the resistor tonight and hope that solves it all. I haven't checked the coil, I have always been under the impression that a coil either worked or it didn't. Might be wrong. It's too simple a system to be this much trouble  Let you know later how it turns out.

|

|

|

|

|

pcmenten

|

|

|

Group: Forum Members

Last Active: 8 Years Ago

Posts: 375,

Visits: 1.1K

|

I wonder if he's got a 6v starter. A 6v starter might spin the motor right over but draw too much current to allow a good spark. Try running the ignition from a separate battery.

Edit: have you checked the coil? Measure its resistance.

Best regards,

Paul Menten

Meridian, Idaho

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

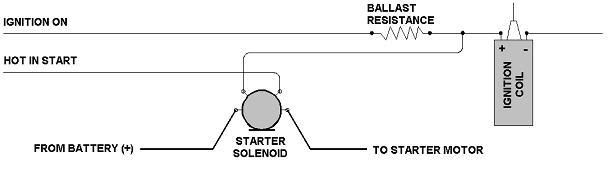

I've got this little diagram that shows the jumper from the four post starter solenoid.....

It just uses the fourth post (hot when the solenoid is energized) to provide as high a voltage as the battery can muster - directly to the ignition coil when starting. The battery voltage "sags" when you put a big load on there - the jumper around the ballast resistor keeps the coil voltage from going so low it won't make a good spark.

Steve Metzger Tucson, Arizona

|

|

|

|

|

uncleaud

|

|

|

Group: Forum Members

Last Active: 13 Years Ago

Posts: 62,

Visits: 863

|

I've got Rotella oil and STP additive plus everything was put togeather with assemby lube of course. My plan is to start it up (if and when) run it up to 1000-1200 rpm, let it come up to temp and hopefully run that way for 15 20 min. without getting hot on the temporary radiator and elec fan. After it cools down I will repeat the thermal cycle at least a couple times plus probably as many time as a buddy shows up and wants to hear it run  Think that should break the cam in enough not to have any major worries. Any other suggestions are appreciated. It's the first y-block I'v built, far fromt he first motor I've built but the first y-block. Looks like it should be a pretty foregiving motor if I done my homework. I'm sure it's put togeather better than Henery did the first time

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 3 hours ago

Posts: 6.1K,

Visits: 442.9K

|

Another thing that caught my eye. The motor is new. So are the cam and lifters new or reground? If so, set it up so you can break it in properly. You don't want to start it up for a minute and then put it away for a year with a new cam. You'll wipe all of the assembly lube off. When you start it up a year from now the results probably won't be favorable.

Lawrenceville, GA

|

|

|

|

|

uncleaud

|

|

|

Group: Forum Members

Last Active: 13 Years Ago

Posts: 62,

Visits: 863

|

My grounds are good. The cables are new, the block and all connections are clean. One cable goes to the starter lug, the ground cable is attached to a bell housing bolt. As nothing is drawing juice except the ignition the chassis shouldn't need grounded I don't believe. I can get around the resistor with no problems my concern was as you stated. I should get enough spark through the resistor to run the motor. If I jump past the resistor to make it run and eleminate it from the system, the worst that would happen is I might burn up some points, thats cheap enough to hear it run. Could very well be a bad resistor, In the famous words of Sherlock Holms, "Its all elementary Watson. It must of been too obvious and too late last night. Now to go after that new out of the box Holly that leaks out of every joint from a bad back float. So much for factory adjustment. I remember this being more fun when I was younger

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 3 hours ago

Posts: 6.1K,

Visits: 442.9K

|

The coil does get a full 12v when starting. The resistor is easy to bypass with a jumper lead when starting. But, you say that the spark is not strong enough to fire with the resistor in place, which is how it will be operating when running so you need to figure out why. Check all of your grounds. Make sure you have a good path to ground. The distributor may not ground well through the block. Use a jumper from the ground side of the points to a good chassis ground. This will eliminate any problem there. Check the voltage before and after the resistor.

Lawrenceville, GA

|

|

|

|