Depending on the rebuilder - many of the later versions use the small block Ford distributor body (with a y-block compatable shaft). It has a "three lobed" shank running down from the distributor body to the clamping base.

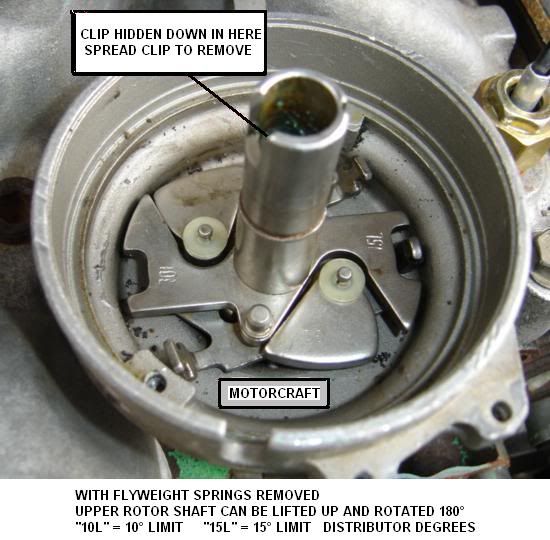

This is a "Motorcraft" distributor and the advance mechanism down inside will look like this....

The older design "Autolite" base has concentric rings around the shank like this one and the advance mechanism will differ. It will have kidney shaped flyweights with bronze bushings at the pivots.

The upper rotor shaft - that carries the point cam for the Motorcraft set-up will have a choice of two internal advance stops. They will be stamped as shown in the photo above - this one has "10L" and "15L" markings. Others can be found as well and parts can be swapped around - I usually hunt for and use the "13L" versions and they are often paired with an "18L" stamping. The tab sticking up from the base (at right in the 15L slot) sets your choice of the advance "range" (usually found with a small piece of black plastic tubing forced over it). By removing the advance springs and a clip down in the well at the top - you can spin these upper rotor shafts 180° and choose the other range of travel. So this one shown has a choice of 10° - or 15° of distributor advance - which will be 20° or 30° at the crank timing marks.

Total advance for one of these engines (that is pretty much stock) should be limited to something like 36° / 38° (with no vacuum advance). The initial advance you set at idle and distributor centrifugal advance is summed as the engine accelerates, so the rotor shaft shown could be used with 16°/18° initial and the "10L" slot - or 6°/8° with the "15L". If you want to use a different initial setting and have this pretty much figured out - you can "customize" a "10L" slot to be what you need with a rat-tail file. Just remember its easier to make them longer than shorter.... A slight increase in one of the settings can be had by simply removing the little piece of black tubing off the travel pin.

The common Y street engines like a lot of initial spark advance - 10° is a good start - but the choice of initial turns out to be a decision based on use of "live" manifold vacuum advance or "ported" vacuum advance from a specific port on the carburetor. There are proponents of both and they both can work well. My outfit runs 10° initial and live manifold vacuum - I believe that makes it start a bit quicker - and several I know use 14° initial with ported. We all end up at nearly the same 36°/38° total mechanical advance. The ported vacuum comes from a hole just above the throttle plate of the carb - so when you open the throttle, it "turns on" vacuum to the distributor and it becomes virtually the same as live manifold vacuum below the throttle plates. So it is basically using the throttle as an on-off switch for vacuum advance at idle. Keep in mind that using low amounts of initial advance - and ported vacuum - can result in the engine running relatively retarded and heat up at long periods of idle.

Springs for the centrifugal advance unit - get a set of Mr. Gasket 925D springs so you can play with the speed at which the full advance is in the engine. It will depend on engine compression - and what sort of go juice you get at the pump locally - to determine how fast you want the curve to operate. Generally 3000 rpm is a conservative, safe "all in" value - but the lower you can make it all come in without knocking, the more "bottom end" you will build into your power curve. Where you start is a judgement call - but getting it perfecto on the first try is hard to do. There is a real advantage to knowing someone with an old style SUN distributor machine that can dial this in on a bench. Fact is, that many have learned to "curve" their distributors right at home in the driveway - so it is a time honored automotive tradition.

The vacuum pots come in two varieties - an older version seen below.....

and another newer set-up that may or may not have an internal adjustment screw.

The older version can be disassembled to adjust both the full travel - and the spring rate. There is a bakelite tube inside controlling the travel - and the spring and shims are self explanatory. We have made longer pieces of tubing out of carbon fiber arrow shafting - but it doesn't have to be exotic. The vacuum advvance is a street tuning thing - it adds advance at low engine load to gain fuel economy. High engine vacuum indicates light load - vacuum adds advance - low engine vacuum says the throttle is way open and reduces advance to the mechanical (no-knock) settings.

This will get you started - ask more questions!

Steve Metzger Tucson, Arizona